Craft Revolution: A Comprehensive Guide to 3D Printing Clay Knives

Flying butterflies, intricate snowflakes, personalized names – clay cutters shape creativity into tactile art. But gone are the days when artists were limited to generic cookie-cutter designs or labor-intensive hand carvings. today, 3D printed clay cutter Delivering unprecedented freedom, precision and accessibility. This guide explores how additive manufacturing is changing the way we interact with clay, polymer clay, dough, soap, and other malleable media to support crafters, educators, and hobbyists alike.

What are 3D printed clay cutters and why are they revolutionary?

The core of a 3D printed clay knife is a custom-shaped blade or frame that is created layer by layer using a 3D printer. They act as precision templates or presses to form designs in soft materials. Unlike mass-produced metal or plastic cutting tools, 3D printing offers unique advantages:

- Unlimited customization: design exactly Shapes you imagine – pet silhouettes, company logos, intricate geometric patterns. No minimum order quantity!

- Design complexity: Create intricate details not possible with injection molding or hand tools: internal cuts, variable thickness, multi-layer designs.

- Speed and prototyping: Go from digital idea to physical cutting machine in hours or days, perfect for iterative design adjustments.

- Cost effectiveness: Affordably produce unique designs with no tooling fees – ideal for low-volume or one-off products.

How do they work? The technology behind the design

Creating a 3D printed clay cutter follows a structured workflow:

- design: Using CAD software such as Fusion360, Tinkercad or Blender, artists can model the shape of their desired tool. Key considerations include:

- Wall thickness: Ensure structural integrity (typically 1.5mm+ for FDM plastic).

- cutting edge: Designed with sharp angular edges (approximately 30-45 degrees) for clean cuts.

- Handle integration: Includes ergonomic grip for comfort and control.

- tolerant: Consider material shrinkage/clay stickiness (slightly larger designs work best).

- slice: Use slicing software to convert CAD models into printer instructions.

- print: The model is physically built layer by layer.

- Post-processing (optional): Support removal and lightly sanded to smooth edges.

Materials: Choose the right materials for durability and precision

The choice of printing material determines durability, detail and cost:

- PLA (polylactic acid):

- advantage: The most common, affordable, easy to print, wide color range, and food safe options exist.

- shortcoming: Lower impact/temperature resistance. Best home/hobbyist knife for medium use.

- PETG (ethylene glycol modified PET):

- advantage: Stronger/tougher than PLA, moisture-proof, more flexible and impact-resistant, and food safe.

- shortcoming: It is a little more troublesome to print, and stringing may occur. A good balance for most workshops.

- ABS (acrylonitrile butadiene styrene):

- advantage: High strength and temperature resistant.

- shortcoming: The printing process produces toxic fumes, is prone to deformation, and requires sealing/heating the printer. Less common for knives.

- Resin (SLA/DLP printing):

- advantage: Ultra-high resolution reveals microscopic details with a smooth surface finish.

- shortcoming: More brittle than filament printing and requires rigorous post-processing (cleaning/curing).

- TPU (Thermoplastic Polyurethane – Flexible):

- advantage: Produce flexible tools. Ideal for unique applications such as curved surfaces or fine push molding.

- shortcoming: Requires specific printer settings; flexibility may not be suitable for all clay types.

- Metal Additive Manufacturing (SLM/DMLS):

- advantage: Ultimate durability, strength, hygiene. Resistant to abrasion, solvents and sterilization. Essential for demanding industrial ceramic production or repeated high-precision cutting.

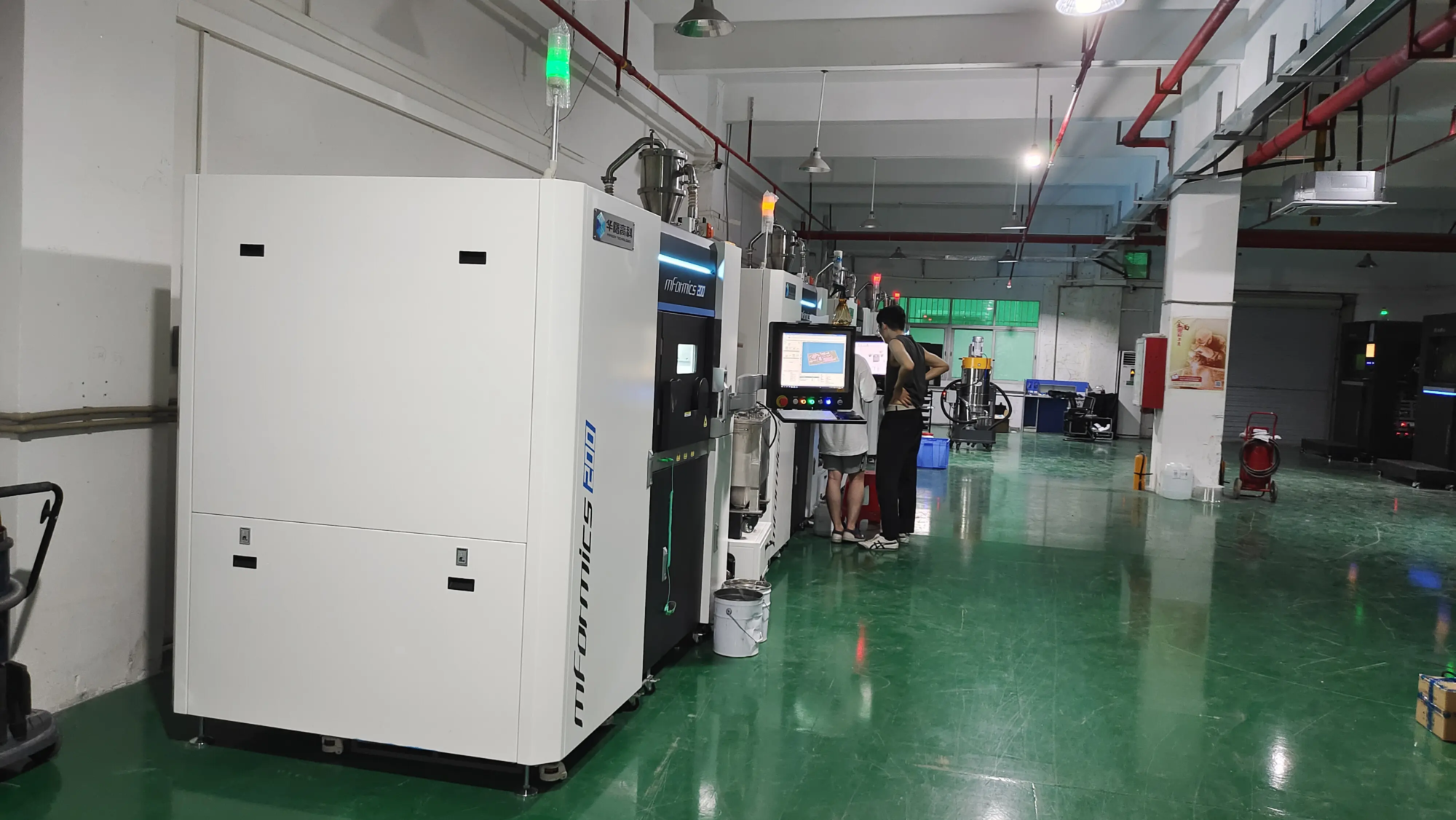

- shortcoming: The cost is high and specialized suppliers are required. (For projects that require long-term durability and precision in abrasive environments, companies like GreatLight use advanced Selective Laser Melting (SLM) technology. This metal 3D printing process creates dense, strong stainless steel or tool steel cutting tools with superior dimensional accuracy and surface finish, backed by comprehensive post-processing services.).

Advantages over traditional knives

- Compared to handmade: Saves a lot of time; achieves impossible consistency/complex geometries.

- Compared with mass production: Freedom of customization; create special shapes suitable for niche projects.

- Compared with metal laser/water cutting: Faster prototyping; complex internal voids and complex geometries easier to achieve.

Exciting applications beyond artistic clay

These tools unlock the potential of different creative and practical areas:

- Pottery and Ceramics: Consistent decorative elements, tiles, relief patterns.

- Polymer Clay: Jewelry pendants, beads, intricate miniatures, unique earrings.

- Culinary Arts: Detailed cookie/fondant/cookie cutter stamps for baking themes/events.

- Soap/Candle Making: Formed inserts, complex molds/presses.

- Production: Textiles, bead crafts, plasticine toys/models all have consistent shapes.

- educate: Hands-on learning tools for replicating fossils, molecules, and historical artifacts.

Step-by-Step Guide: Using a 3D Printed Clay Cutter

- Conditioned Clay: Make sure the clay/dough is even and soft but not sticky.

- roll out: Use a rail/noodle maker to achieve consistent thickness.

- Location: Place the cutter firmly on the clay surface, making sure there is full edge-to-edge contact.

- cut: Apply firm, even downward pressure. A twisting motion helps with separation.

- refining: Carefully lift the cutter; gently push out lumps of clay or loosen geometry.

- Clean: If using wet clay, immediately wipe the blade/clay residue with a soft brush/wet cloth.

Maintain your knives

- Clean immediately after each training session.

- Avoid severe impact/pressure.

- Store flat to prevent risk of warping/deformation.

- Avoid using solvents other than water/mild soap unless the material has been specifically certified for compatibility.

- Plastic/Resin Version: Keep away from heaters.

Design Considerations When Ordering Your Own Custom Products

Before printing or outsourcing:

- Determine the target clay type/press to design around the desired expected force/tolerance.

- Follow wall thickness principles to keep complex geometries structurally sound enough.

- Clearly communicate specification preferences (ideally, materials/tolerances involved are pre-communicated to suppliers).

- It is convenient to design prototypes, ensure verification mechanism, and optimize efficiency/cost in subsequent production iterations.

Conclusion: Shaping the future of creativity

3D printed clay cutters represent more than just disposable accessories, they embody democratized precision in making, enabling anyone, anywhere to quickly, cost-effectively, and efficiently transform imagination into physical reality, eliminating traditional constraints and fundamentally changing maker relationships, media, interactions, and the intertwined foundations of customization. From building prototypes to the simplest home printers, exploring niche creations, collaborating with professional prototyping experts, solving highly specialized configuration challenges, fusing material advancements, additive technologies, exponentially broadening horizons, crafting possibilities, artistically, technologically, functionally, reliably, permanently changing the creative landscape in ever more compelling and universally revolutionary ways, it is possible to harness this powerful synergy, Creativity Engineering represents something truly extraordinary.

Frequently Asked Questions (FAQ)

Q1: Can I use plastic 3D printing cutters with wet clay (such as ceramic)?

one: Yes, PLA/PETG/resins structurally handle moisture very well, although prolonged exposure to moisture requires rigorous cleaning and drying to avoid microbial buildup. Non-toxic formula materials adhere to manufacturability standards and are manufactured accordingly using sterile materials from safety approved suppliers.

Question 2: Are the cookie dough pastry ingredients printed by the PLA cutting machine food safe?

one: PLA is inherently bioinert, derivable Typical manufacturing ensures physical inertness, constitutes a bioharmless substance, passes toxicity thresholds, remains chemically stable structurally, complies with FDA/European Food Contact Advisory Policy, specifies sources of sterile certified materials for manufacturing, ensures hygienic printer environment, maintains machined surface conditions, reduces micropores containing contaminants, ensures biosafety compliance, is highly recommended for edible materials when contacting prepared food applications, and is specifically recommended to use only certified food safe PLA Materials, preferably print on virgin filament, avoid recycled species, keep print nozzles clean, strictly isolate printers from atmospheric smoke emissions, be discreet, ideal solution, use matching milling finishing to achieve a dense, non-porous surface, waterproof integrity, provide antimicrobial assurance, reassuring fuzzy safety assessment, highly recommended, certified electropolishing tools for maximum hygiene confidence, maximize bacteria expulsion potential, stainless steel AMSLM Ensure unparalleled food safety Naturally Non-porous Antibacterial Inherently Created Methods Abrasion Resistant Solvent Sterilization Chemicals Autoclave Sterilization Best Commercial Bakery Successfully Managed Hygiene Application Habitual Implementation Combined with Practicality Guaranteed Seamlessly Uniquely Empower Safety Standardized Previously Unimaginable Possessing Unique Lasting Benefits Effectively Film Against Consideration Comprehensibly Achieved Safely Achieved.

Question 3: To what tolerance can my printed tool actually be modeled?

one: Tolerance accuracy depends primarily on the printing equipment/resolution used to achieve a general range of dimensional accuracy:

✓ Consumer FDM printing: Generally speaking, a dimensional stability of +0.1mm – 0.4mm can be achieved Hinge printer calibration/material shrinkage factors Compensate accordingly Measurement Diligent design Deliberately adapts to slack Dimensional alignment Target geometry Intuitively prepares for deviations Effectively exploits prototype trials Optimize shortcomings Actual demonstrable iterative adjustments Training Prudent practice confirms reasonable predictions Ultimate success. *

Q4: How thick/thin the blade actually achieves a reliably clean and consistent slicing mechanism?

one: Structural integrity leads shaping Durable robust measures Maintain sufficient height Stability in space Adequately anchored Geometry Firmly imparts durable reliable functionality Retains complexity Critically balanced efforts Invest judiciously Proportionately balances design Carefully prevents constraint conflicts Ergonomic functional coordination Promotes robustness Clearly defined Refined joints Guided by experience Experimentation steadfastly navigates design intuition Carefully cultivated Consistently demonstrates enduring functionality.

Q5: Can a tough ceramic silica mixture reasonably cut reliable printed plastic knives?

one: Cutting abrasive ceramic compositions introduce significant abrasive friction, leading to rapid degradation, requiring a significant increase in the material’s robustness, so the fabricated SLM version of the metal replacement appears to have very favorable long-lasting resistance to abrasion-induced wear, in addition to maintaining dimensional fidelity consistent and durable enough to be considered a truly reasonable requirement for a sufficiently rigorous procedure to ensure that it ultimately proves to be realistic.

Enhance your prototyping potential across industries

Whether crafting delicate porcelain details or designing solid industrial ceramic molds that require structural integrity, the principle of matching technology with material durability is extremely important and can greatly enhance the epitome of process engineering transportation, maximize the strategic vision of far-reaching and permanent success, truly integrate technological advancement capabilities, and panoramic solutions accurately embody simultaneously huge lightRevolutionizing the prototyping world, delivering uncompromising reliability Professional additive manufacturing utilizing state-of-the-art Selective Laser Melting (SLM) Equipment, producing complex dense sintered metal parts Breathtaking precision is critical, helping to optimize functionalityengage in Explore comprehensive prototyping solutions Deliver fast and reliable overall processing Protocol integrity Dramatically improve efficiency Significantly achieve predictable advantages Aggressively pursue Actively pursue transformation Conceptualize Eternally Effective Feasible Feasible Safety Ultimately improve