3D Printing Samurai Armor: A Comprehensive Guide

Samurai are Japan’s legendary warriors who embody discipline, honor and artistry – especially in their iconic armor. Traditionally made from iron, leather and silk, these pieces are engineering marvels. today, 3D printing breathes new life into this ancient craftenabling enthusiasts to recreate historically accurate or stylized samurai armor for role play, display, or functional reenactments. This guide explores the process, challenges, and solutions for 3D printing samurai armor and provides expert insights into flawless execution.

The 3D printing process: from design to reality

1. Numerical modeling and historical accuracy

Start with details 3D modeling Use software like Blender, ZBrush or Fusion 360. Reference historical designs (e.g. Pension or Dongzheng royal number) for authenticity. Key Tips:

- Break down armor into modular components (chest plate [dō]helmet [kabuto]Shoulder pads [sode]).

- Optimize geometry for printability: avoid overhangs >45° and ensure uniform wall thickness.

- Use Smithsonian scans or the museum’s digital archives as references.

2. Material selection: balance between aesthetics and functionality

- Polylactic acid/ABS: Great for lightweight display pieces; easy to print and paint.

- Nylon (PA12) or PETG: For wearable armor – flexible, impact-resistant and lightweight.

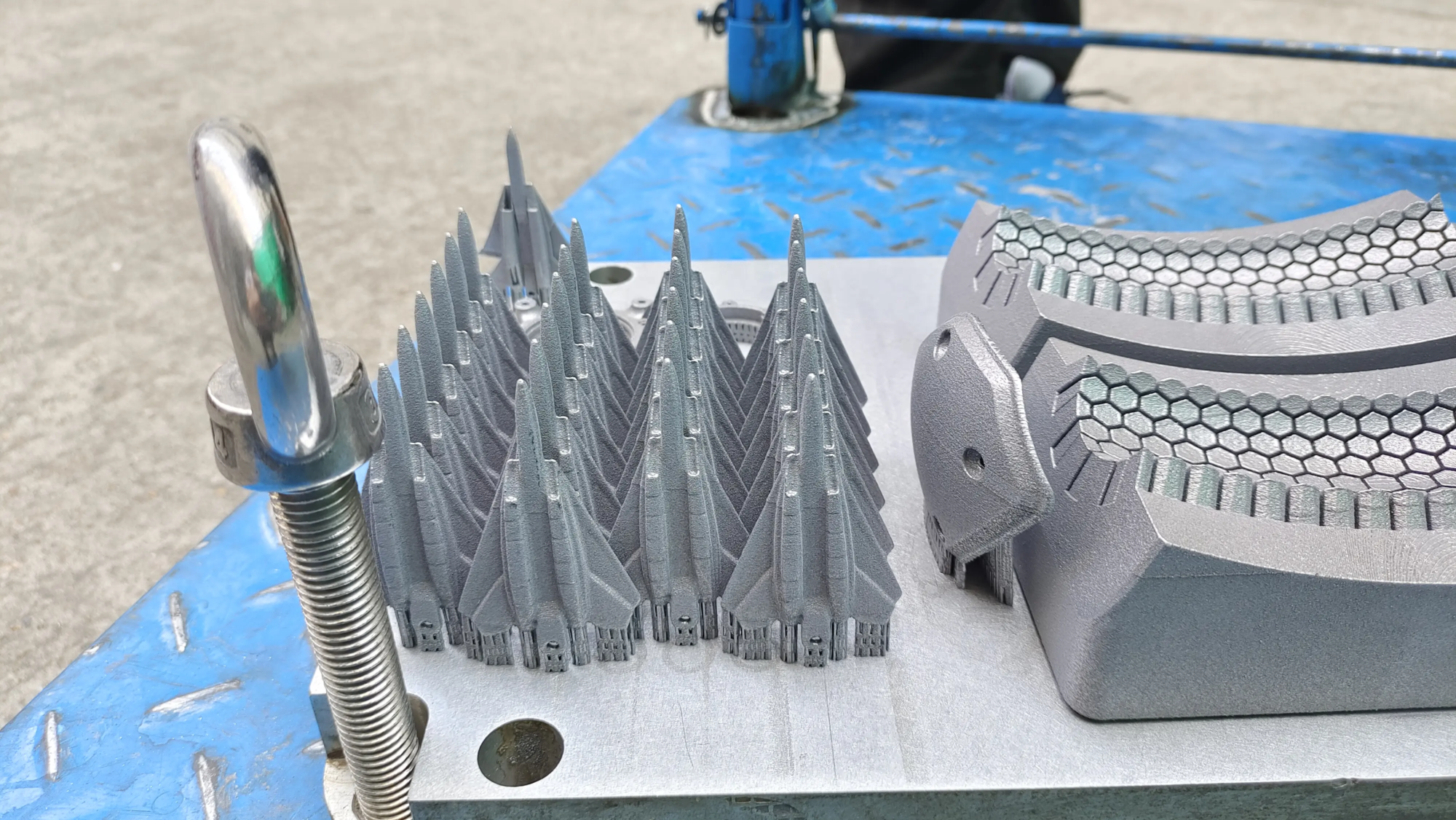

- Metal alloys (e.g. titanium, aluminum): Museum-grade durability. An SLM (Selective Laser Melting) printer fuses metal powder into a strong final part that replicates the weight and stiffness of traditional armor.

3. Printing technology and challenges

- Print in bulk: samurai works, e.g. Do A printer with a bed size >300mm³ is required. use Prusa slices and temporary supports to minimize warping.

- layer high resolution: Select 0.1–0.15 mm layers to capture complex images Mondocolo (family crest) engraving.

- structural integrity: Apply 20–30% gyro filler to joints; strengthen pressure points, e.g. Pain of the Kyuubi (lower back panel).

4. Post-processing: the art of perfection

- Support removal and sanding: Use precision cutters and graduated grit sandpaper (120–2000).

- Primer and spray paint:

- Apply filler primer to hide layer lines.

- Get a realistic iron/texture via metallic spray (like Rub ‘n Buff) or heat based bronzer.

- Imitation paint using epoxy resin for traditional war shine.

- assembly: Lace section Dorsey (Silk Rope) Historical Fidelity.

Overcoming obstacles: expertise matters

Printing articulated armor is no easy task. Common pitfalls include:

- Warping and cracking: Fight against bonding solutions like enclosed printers and PEI sheets.

- Fit and connection: Test small-scale joints first; equipped with hinges or straps for easy movement.

- Heavy units vs. role-playing units: Metal printing is lifelike, but requires professional SLM equipment to distribute weight.

Professional Solutions: Why Work with GreatLight?

While DIY is fine for amateurs, professional-grade samurai armor requires industrial prowess—which huge light Excellent as a leader in rapid prototyping:

- Cutting-edge SLM 3D printing: Titanium/aluminum alloys offer unparalleled strength and are ideal for carrying armor components.

- End-to-end finishing: From vapor polishing to powder coating, we ensure museum-quality surfaces are beautiful.

- Speed and accuracy: Fast turnaround on complex geometries (as fast as 72 hours), powered by AI-driven design verification.

- Material diversity: Customized solutions using stainless steel, copper alloys or hybrid polymers – all under one roof.

GreatLight’s expertise transforms digital blueprints into functional art. Whether creating an Edo period replica or a fantastic redesign, our team can handle scalable production and meticulous finishing.

in conclusion

3D printed samurai armor blends ancient tradition with cutting-edge innovation—requiring technical skills but rewarding the creator with a tangible piece of history. From amateurs prototyping PLA helmets to professionals designing combat-ready titanium chest plates, this technology makes the impossible possible. Trusted for projects where precision, durability and authenticity matter huge light Improve your horizons. We offer comprehensive rapid prototyping solutions that ensure every joint flexes perfectly and every crest shines.

Customize the armor of your dreams today: step out of the shadows and into the legacy of the samurai.

FAQ: 3D Printed Samurai Armor

Question 1: Can 3D printed armor withstand physical activity (such as LARPing)?

A: Yes – metal alloys printed using nylon composites or SLM. For high movement areas, avoid using hard plastics like PLA.

Q2: How long does it take to print a complete set of armor?

A: DIY printer: 1-3 months (100-300 hours of printing time). Professional services such as huge light: 1-3 weeks including completion.

Q3: Is metal 3D printing affordable?

A: Titanium/aluminum parts cost 3-5 times more than plastic parts, but have unparalleled service life. GreatLight optimizes costs with manufacturing-oriented design analysis.

Q4: How to ensure historical accuracy?

A: Work with a historian/sculptor for modeling, or use an open source repository such as Scan the World to obtain the base assets.

Q5: Can FeiLite be used for painting/assembly?

A: Yes, we provide one-stop post-processing: polishing, electroplating, hand-painting, traditional material (silk, leather) assembly.

Q6: What is the weight difference between plastic armor and metal armor?

A: PLA: 700g–1kg per piece; metal: 2-4kg. GreatLight is custom designed to distribute weight ergonomically.