Power Your Project: An Essential Guide to 3D Printing Durable Tank Tracks

The sight of tank tracks—relentless, powerful, terrain-conquering—evokes raw engineering ingenuity. Today, 3D printing brings this capability directly to your workshop or design office, empowering hobbyists, engineers, and manufacturers alike. Whether you’re producing detailed scale models, building rugged remote-controlled vehicles, prototyping novel industrial conveyor systems, or testing specialized mobility solutions, mastering 3D printed tank tracks can unlock huge potential. However, these components face unique pressures that require careful consideration of design, material selection, printing techniques and finishing. This guide takes an in-depth look at the key factors in creating practical, reliable 3D printed tank tracks.

Beyond Aesthetics: Understanding the Challenge

Tank tracks are not static components; they are dynamic systems subject to brutal forces:

- Continuous bending and impact: Each link flexes significantly as it rolls over the wheels/idlers and impacts uneven terrain.

- Shear and tensile forces: The connecting rods pull against each other under torque and experience lateral stresses.

- Wear: Continuous contact with the ground, wheels and adjacent links wears away at the surface.

- Complex geometric shapes: Pin joints and interlocking mechanisms require precision.

Failure usually manifests itself as pin/sidewall breakage, cracked links, or excessive wear at the hinge points. Success depends on mitigating these failure modes through smart choices at every stage.

Phase One: Basic Design Selection

-

Linking geometry is crucial:

- Pins and integrated hinges: Individual pins offer modularity and potential strength, but require precise printing and assembly. Integrated hinges simplify printing, but require careful design to avoid weak links in the hinges. Flexible filaments are often effectively used in integrated designs.

- Side wall thickness: Too thin = brittle, too thick = heavy and inflexible. Smartly reinforce high-stress areas with ribs or gussets.

- Lubrication path: Consider channels or low-friction pads where the links rub against each other.

- Guide teeth: Essential for tracking alignment. Designed with sufficient height and strong root attachment.

- Optimize printing direction and support:

- Prioritize strength: Orient the links so that the ply lines are parallel to the direction of the primary tensile load (e.g., along the length of the pin). Avoid placing critical structural elements perpendicular to the build plate, as weak layer adhesion can have catastrophic consequences.

- Minimize support: Strategically design overhangs or angled features below critical thresholds. Soluble supports can illuminate complex geometries buried within components.

Phase Two: Materials – Matching Performance to Needs

The harsh working environment places stringent requirements on materials. While PLA is great for static display models, the functional rails need to be better:

-

Nylon-based filament (PA, PA-CF, PA-GF):

- advantage: Excellent toughness, fatigue resistance, impact strength, wear resistance (especially CF/GF filled variants). The natural friction coefficient is low.

- shortcoming: Hygroscopic (requires drying), challenging printing (warping, requires heated chamber/hot end), surface finish may be rougher. PA-GF is more rigid and PA-CF has excellent wear resistance/surface finish.

- Best for: High performance RC models, industrial prototypes that stand up to wear and tear.

-

PETG and PETG-CF:

- advantage: It has a good balance of strength, toughness, and chemical resistance, and is easier to print than nylon. Less hygroscopic. PETG-CF significantly increases stiffness and wear resistance.

- shortcoming: It is naturally less slippery than nylon and may be sensitive to notches.

- Best for: Sturdy RC rails, functional prototypes require better durability than PLA.

-

Flexible filament (TPU, TPE):

- advantage: Excellent impact resistance and inherent flexibility simplify articulation. Typically fewer pins/complex hinges are required.

- shortcoming: Significant horizontal expansion during printing requires careful calibration. May be susceptible to wear and permanent deformation over time.

- Best for: Smaller scale models, racetracks requiring extreme consistency, damped prototypes.

-

Advanced polymer powder (nylon 11/12, TPU):

- advantage: Excellent isotropic mechanical properties, intricate details, excellent surface finish, complex geometries, and no problematic supports.

- shortcoming: High cost and requires the use of SLS/SMJ/MJF printers.

- Best for: Complex designs require maximum polymer performance and detail.

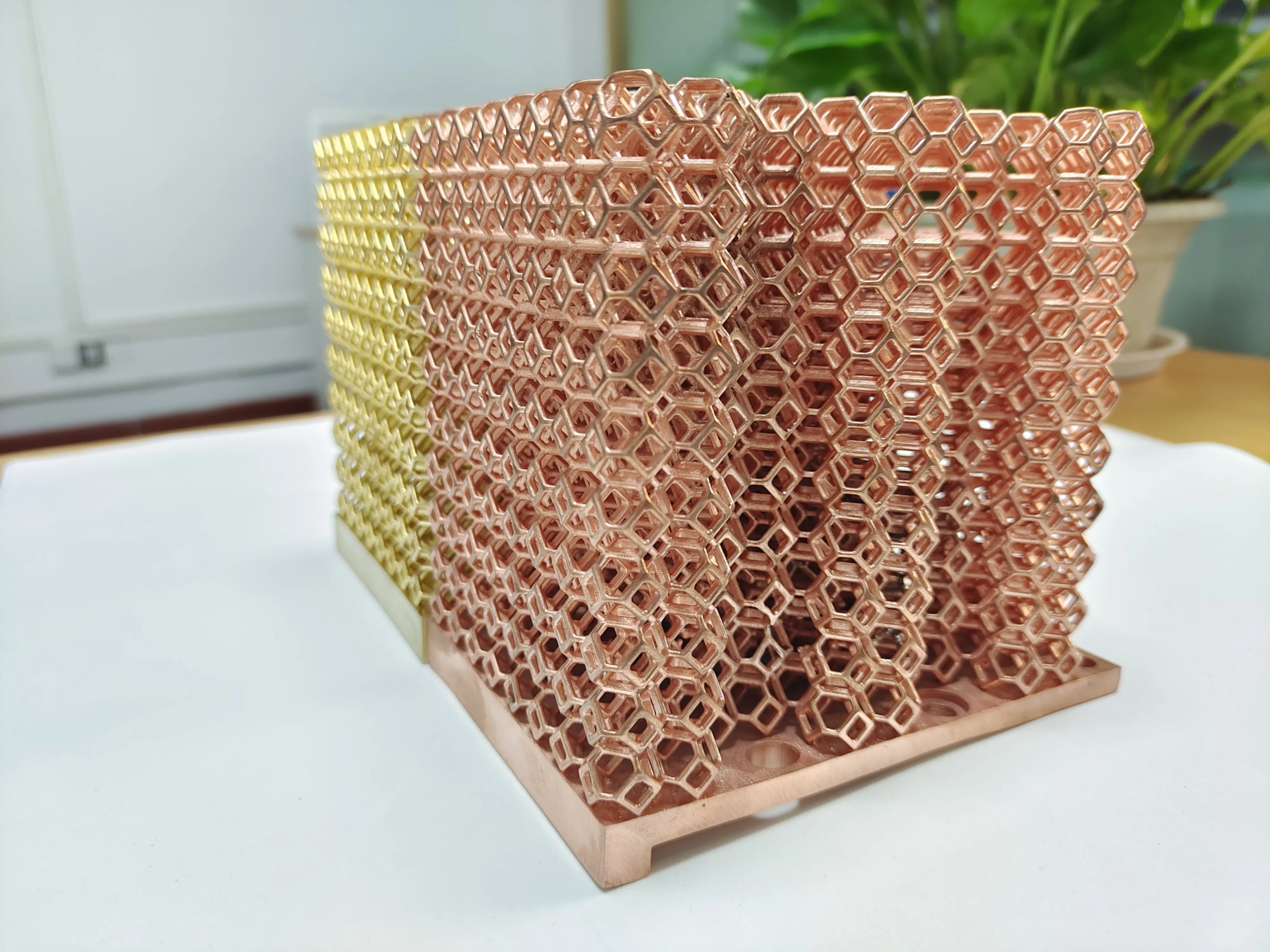

- Metal powder (stainless steel, titanium, aluminum alloy):

- advantage: Unparalleled strength, wear resistance, fatigue life and temperature resistance. Crucial for demanding industrial machinery or aerospace prototypes.

- shortcoming: Significant increase in cost and complexity (requires SLM/DMLS printer). Advanced post-processing is required.

- Best for: Full-scale industrial equipment tracks and ultra-high-performance prototypes place high demands on metal performance.

The third stage: Optimize the printing process-rigor is the key

- Calibrated perfectly: Bed leveling, extruder E-step, flow and PID adjustments must be accurate. A track is only as strong as its weakest printed layer.

- Strong layer adhesion: Increase the nozzle temperature slightly (within the material limits), optimize layer height vs. line width, ensure adequate extrusion width, slow down the print speed on critical layers, and use shells (especially for nylon/engineered polymers).

- Volume flow limit: Know your hot end’s maximum volumetric flow capability. Pushing too fast creates weak layers—affecting speed rather than strength.

- Support strategy: Choose supports carefully. Tree supports minimize contact points. Consider the detached soluble interface in critical areas.

- Fill strategy: A high fill percentage near hinge points and pins is critical. Use fill patterns such as spirals or straight lines to provide good all-around strength. A solid top/bottom layer is non-negotiable.

- Low speed test: Slowly print individual links before doing a full trace to test interlocking, pin fit, and strength.

The fourth stage: critical post-processing

- Thorough cleaning: Carefully remove all support material, especially from the pin holes and bearing surfaces. Compressed air and a special pick/scraper are essential. Smoothing may be beneficial for nylon tracks.

- Precision assembly: The pins must fit snugly and not jam. Light lubrication using PTFE spray, silicone oil or special grease can significantly reduce friction and wear. Dry lubricants such as graphite/molybdenum disulfide are ideal for hot environments or pollution issues.

- Heat treatment (metal): Stress relief annealing is critical for DMLS/SLM rails to prevent premature cracking under load. HIP can significantly improve fatigue life and eliminate porosity.

- Surface enhancement: Shot peening improves the fatigue resistance of metals. Hard coatings such as tungsten carbide or DLC for HVOF applications can improve wear resistance.

- verify: Destructive testing of alternate links can help quantify strength limits. Non-destructive testing (metal dye penetrants, magnetization/sound inspection) ensures integrity.

Conclusion: Improving potential through advanced prototyping

3D printed tank tracks represent an exciting intersection of complex engineering challenges and advanced manufacturing possibilities. Success requires more than just hitting the ball "Print";It requires meticulous engineering thinking in design, materials science, process parameter optimization and post-manufacturing finishing.

For prototypes that go beyond hobby-grade materials or complex designs that require performance-grade polymers or metals, working with an expert prototyping service becomes extremely valuable. GreatLight is a dedicated rapid prototyping partner equipped with cutting-edge industrial SLM 3D printers and a comprehensive suite of finishing technologies. Our deep expertise in metal powder bed fusion (SLM/DMLS) provides unparalleled strength and durability for tracks that need to perform like pure steel under intense pressure. In addition, our expertise extends to high-performance polymer processes and meticulous post-processing, including certified heat treatments and advanced metal surface coatings. If your project involves driving innovation through custom-designed mobility solutions, conveyor systems, or specialized crawler prototypes that require precision machining and quick turnaround, GreatLight provides efficient one-stop expertise. Explore the potential – Submit your track design requirements today and take advantage of true industrial-grade rapid prototyping capabilities at a competitive price.

3D Printed Tank Tracks FAQs

- Q: What material is best for tank tracks?

- Answer: There is no single "The best." This depends heavily on the application:

- Functional RC/Rugged Model: PA-CF (nylon carbon fiber) or PETG-CF provide an excellent stiffness/weight/wear balance.

- Small scale/high consistency: TPU works great.

- Ultimate Performance/Durability: SLM/DMLS metals (stainless steel, aluminum) are unmatched.

- Balanced prototyping: PETG is a good overall value.

- Answer: There is no single "The best." This depends heavily on the application:

- Q: Why do my plastic tracks keep breaking?

- A: Common culprits: Print pin perpendicular to the print plate (weak layer adhesion), poor pinhole clearance leading to stress concentration, poor material selection (PLA/PETG is brittle compared to Nylon/TPU), pin diameter/insufficient padding around the hole, too high a layer height weakening the pin structure.

- Q: Is flexible filament (TPU/TPE) realistic for large functional tracks?

- A: Suitable for small and medium sizes if printed accurately. Challenges: Tends to stretch/creep under high tension, difficult to print large parts consistently, wear resistance is generally lower than rigid composites/nylon/metals. Offers excellent impact resistance and conformability to uneven surfaces.

- Q: Does the metal 3D printed runway require finishing?

- Answer: Absolutely, and it is of great significance. SLM/DMLS printed metal parts require stress relief annealing to prevent cracking. Removing supports is critical and complex. Surface finishing (grinding, sandblasting, polishing) improves aesthetics and reduces friction. Secondary machining ensures hole and surface accuracy. Coatings significantly improve wear resistance.

- Q: How important is lubrication?

- Answer: Essential for longevity. Dramatically reduces friction, heat build-up and abrasive wear between pins and links, link guides and tread surfaces. Use PTFE spray/dry lube, silicone lubricant (check compatibility) or special grease. Reapply regularly.

- Q: Can I print the entire track assembly in one go?

- A: Integrated hinges can sometimes be used to achieve extremely complex SLS/SMJ designs or flexible TPU printing. However, printing the links individually optimizes orientation/fill strength, facilitates replacement, and simplifies post-processing/support removal, making it a standard approach.

- Q: What’s the key to avoiding excessive track noise?

- Answer: The joint points are smoother. This is achieved by:

- Precise printing ensures a smooth surface.

- Thoroughly clean burr/support residue.

- Make sure the pin hole clearance is correct and don’t be sloppy.

- Lubricate well.

- Consider softer materials or bushing inserts.

- Answer: The joint points are smoother. This is achieved by:

- Q: How scalable is the 3D printed track design?

- A: Expansion involves complex engineering considerations. Simply scaling up small designs often fails for physical reasons (different stress magnitudes). Zoom down Usually works better. Larger tracks require thicker walls, larger pins/pin holes, possibly different materials/structures, and constant re-evaluation of adhesion/layer stress throughout the printing process. For larger feature tracks, working with an expert, especially a metal expert, is highly recommended.

- Q: What post-processing options can extend the life of plastic runways?

- A: Dye/steam smoothing (nylon) improves surface finish and reduces friction/snag points. Annealing PETG removes residual stress. Precision grinding/polishing