The ultimate solution to cable clutter: Design and build the perfect 3D printed USB holder

Tired of the constant tangle of USB cables clogging your desk, drawers, and life? you are not alone. In our increasingly connected world, USB cables for cell phones, external drives, peripherals, and countless gadgets have become a major headache today. Off-the-shelf organizers often fall short and cannot be adapted to the specific combination of cable types, lengths, and connectors you have. This is where precision and flexibility come in 3D printing Really shine with custom solutions: custom 3D printed USB holders.

Beyond the Tangle: The Power of Customized Organizations

Standard USB holder designed for "average" user. But what if your needs are uneven? Maybe you have an unusual combination of USB-A, USB-C, and micro-USB cables. Maybe you need a stand that clips neatly to the side of your standing desk, integrates with a monitor stand, or even mounts inside a drawer for ultimate simplicity. 3D printing enables you to design brackets exactly For you:

- Cable Stock: Slots are designed to fit every connector type and thickness, preventing slipping and tangling.

- Space restrictions: Create a bracket that fits a specific spot on your desk, pegboard, wall, or cabinet. Vertical, horizontal, tilted – the design freedom is unparalleled.

- Aesthetic vision: Match your workspace decor. Choose from a variety of filament colors and plastic finishes, or go for a sleek, professional metallic look.

- Functional additions: Incorporate cable management features like hooks for wrapping excess cables, integrated tabs, or even cubbies for adapters or flash drives.

Design journey: from idea to digital blueprint

Creating the ideal USB stand requires careful planning:

- Needs assessment: What cables do you need to organize? How many of each are there? Where will it live? What are your aesthetic preferences? Draw your ideas!

- Digital modeling: Convert sketches into accurate 3D models using CAD (computer-aided design) software such as Fusion 360, Tinkercad, or FreeCAD. Key considerations:

- Slot size: Sockets are accurately modeled to your actual connector (including tolerances for easy insertion/removal).

- Basic stability: Ensure a sturdy base or secure mounting mechanism.

- Cable path management: Design features (hooks, channels, rails) neatly route excess cable length.

- Strength and durability: Model adequate wall thickness and strong connections between parts (critical for functional parts).

- Virtual prototyping: If possible, use software simulation to check stability and fit before printing. Share the model to get feedback.

Materials matter: choose the right material for your stand

Material choice can significantly affect the look, feel, and durability of your stand:

- PLA (polylactic acid): Affordable, easy to print, and colorful. Ideal as a basic desk organizer. It becomes brittle over time and is easily deformed by heat.

- PETG (ethylene glycol modified PET): Stronger, tougher, and more heat/chemical resistant than PLA. Most desktop USB stands offer the perfect balance of usability and durability.

- ABS (acrylonitrile butadiene styrene): Durable and impact resistant, suitable for functional parts. Due to the smoke, heated beds and ventilated spaces are required. It may become deformed during printing.

- nylon: Extremely strong, durable and flexible. Ideal for parts under pressure. It can be tricky to print, and the filament may need to be dried beforehand.

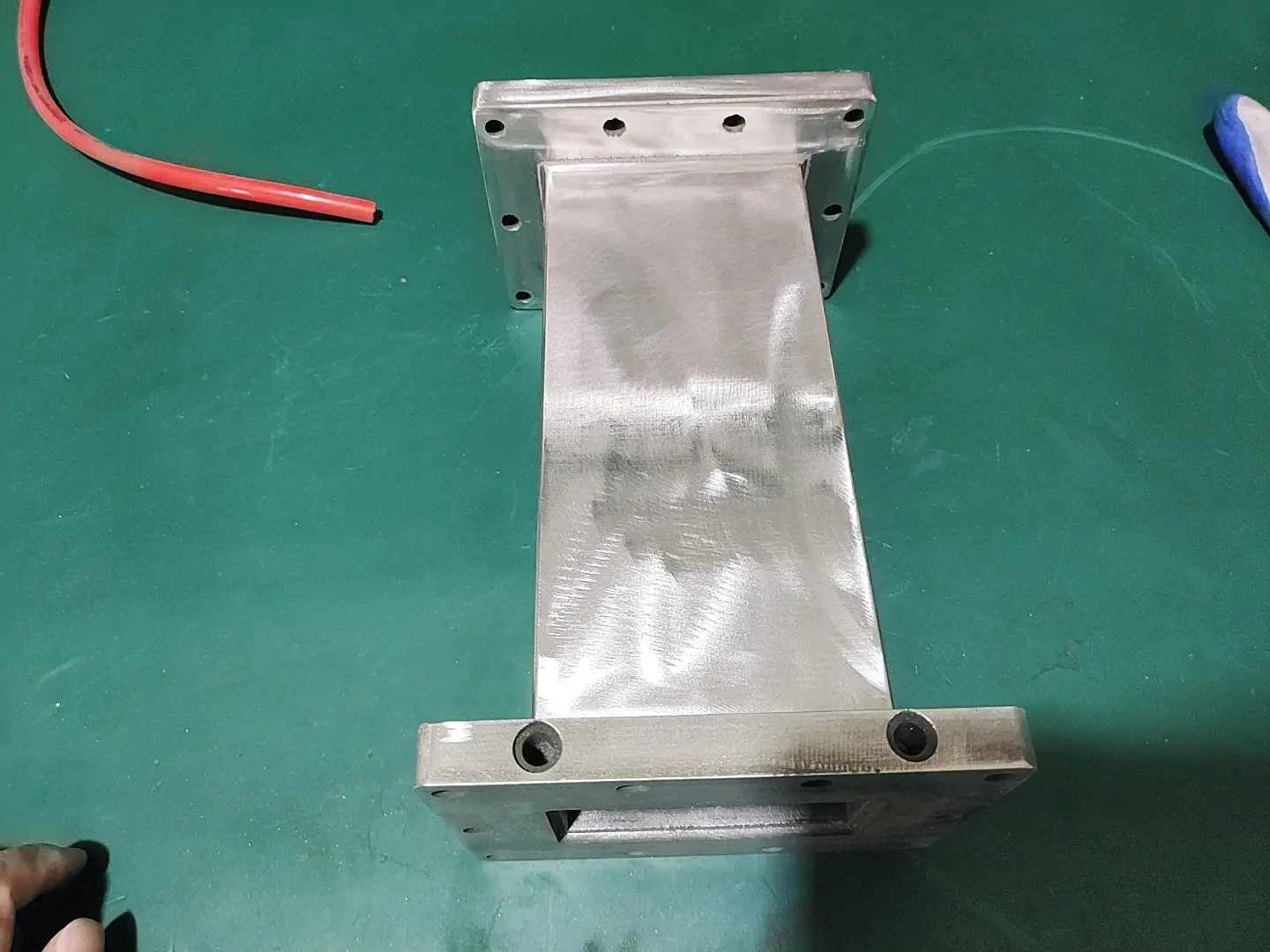

- Metal (stainless steel, aluminum, titanium): The ultimate in durability, strength, heat resistance and beauty. Ideal for demanding environments (e.g. workshops, shared/communal spaces) or a high-end look stand. The process of choice: Selective Laser Melting (SLM). That’s where partners like this come in huge light Leverage advanced SLM technology for outstanding performance.

Unleashing the Power of Metal: GreatLight’s SLM Expertise

When your application requires the highest level of performance or professionalism, metal 3D printing with Selective Laser Melting (SLM) This is often the answer. SLM uses high-power lasers to selectively melt fine layers of metal powder, fusing them together to create extremely strong, dense and complex components directly from CAD models. Why choose SLM as your high-end USB holder?

- Unparalleled Strength and Durability: Metal brackets are more resistant to impact, deformation, heat and wear than plastic brackets.

- Premium aesthetics: Achieve fine, smooth metal surfaces (can be polished).

- Microscopic precision: SLM captures the intricate design details necessary to perfectly fit different connector types.

- Design freedom: Create complex internal structures to reduce weight or unique mounting solutions not possible using traditional machining.

huge lightis a leader in rapid prototyping and precision manufacturing in China, with state-of-the-art SLM equipment and deep additive manufacturing expertise. We don’t just print parts; we provide Comprehensive solution:

- Material Savvy: Expertise in selecting the best metal alloy (stainless steel, aluminum alloy, titanium, etc.) based on your specific stent requirements (strength, weight, corrosion resistance).

- Processing accuracy: Advanced SLM technology ensures precise, high-density printing with minimal internal stress.

- Post-processing mastery: Provide a full range of organizing services:

- Stress relief and heat treatment: Optimizing material properties.

- Precise support removal: Carefully remove support structures.

- Surface treatment: Sand blasting, polishing (mirror, brushed), tumble burnishing for a smooth, professional finish.

- Advanced Coatings: Optional protective or decorative coatings (e.g., anodizing, electroplating of aluminum).

- High Pressure Processing (HIP): Suitable for critical applications to eliminate any residual porosity and maximize strength and durability.

- Expert consultation: Design for Additive Manufacturing (DfAM) guidelines optimize your USB bracket model for functionality and manufacturability on our SLM systems.

From Prototype to Perfection: Why Printed USB Holders Can Improve Your Life

Beyond the prototype stage, a well-designed and reliably manufactured 3D printed USB holder can deliver tangible benefits:

- Instant organization: Eliminate frustrating cable tangles and frantic searches for the right cable.

- Save time: Grab the cable you need now.

- Workspace optimization: Reclaim valuable desk space and create a cleaner, more professional look.

- longevity: A quality bracket, especially a metal bracket, can protect your valuable cables from wear and damage caused by improper storage.

- Customized satisfaction: The personalization aspect is very satisfying – it was designed with an organizer in mind by you, for you.

Conclusion: The future of perfect organization awaits you

The problem of tangled USB cables can be solved. 3D printing enables you to design and create precise The stand you need, perfectly customized to your cables, space and style. Whether you choose a vibrant and functional plastic version that you can print at home, or you’re looking for the ultimate in durability and a premium finish, Metal SLM printed bracketthe organization’s path is clear.

For those looking for peak quality, strength and a professional look, work with professional rapid prototyping experts such as huge light is the key. With our cutting-edge technology SLM 3D printing technology and extensive Organizing serviceswe transform your custom USB stand design into a sturdy, high-precision, and beautiful reality. We are committed to solving complex rapid prototyping challenges efficiently and cost-effectively, providing one-stop solutions and fast turnaround times for custom metal parts. Don’t settle for ready-made frustration. Design it. Print it out. Get organized. Contact GreatLight today for a quote on your custom precision USB stand or any other rapid prototyping needs.

FAQ: Answers to your 3D printed USB holder questions

Q1: Is 3D printing strong enough to create a durable USB holder?

- one: Absolutely! If designed correctly (adequate wall thickness, strong connections) and printed with the right materials (PETG, nylon, ABS), plastic stands are very durable and suitable for everyday desktop use. For industrial environments or demanding applications, Metal SLM printing (as provided by GreatLight) Offers superior strength, heat resistance and longevity that far exceeds that of plastic.

Q2: How to design slots for different USB interfaces?

- one: Measure your actual connector carefully (width, height, thickness). Use calipers to ensure accuracy. Model the socket so that it is slightly larger than the size of the connector (add about 0.2mm to 0.5mm tolerance on each side, depending on material and printer accuracy) to allow for easy insertion and removal without being too loose.

Q3: If I don’t have a printer, can I 3D print the USB holder?

- one: Yes! Options include:

- Online 3D printing services: Upload your design file and choose your material (plastic type, usually metal too).

- Local makerspace/library: Many companies offer 3D printers to the public for a small fee.

- Professional prototyping services (such as GreatLight): Ideal for high-quality plastic prototypes, especially professional-grade metal SLM printed supports with expert finishing.

Q4: What design software should I use?

- one: Beginner: Tinkercad (browser-based, easy). Intermediate: Fusion 360, Onshape, SketchUp (free version for amateurs). Advanced: SolidWorks, Siemens NX. Choose an option that matches your skill level from the start.

Q5: Why choose metal instead of plastic for something like a USB holder?

- one: While plastic works well for many people, metal offers significant advantages:

- Durability: Highly resistant to impact, breakage and abrasion.

- Heat resistance: It will not deform if left in a hot car or near a heat source.

- Premium feel and look: Instantly enhance the aesthetics of any workspace.

- health: Easier to clean thoroughly (important for shared environments).

- weight: Increased stability (alloy dependent).

Q6: How does Honglait ensure the accuracy and quality of the metal USB holder?

- one: Weiguang uses Precision SLM printer Ability to handle complex details. We employ strict process monitoring and quality control inspections. our extensive Post-processing capabilities (Precise support removal, surface finishing techniques such as polishing, heat treatment, HIP (if required)) ensure the final part meets high standards of dimensional accuracy, surface quality and mechanical properties.

Q7: Is Glow’s rapid prototyping service fast and cost-effective?

- one: Absolutely. As dedicated rapid prototyping experts, GreatLight focuses on speed without compromising on quality. Leveraging our advanced technologies (such as SLM) and streamlined processes, we offer competitive prices for: Custom metal parts and deliver prototypes or small to medium batches quickly. Our one-stop service (design advice, printing, post-processing) saves you time and hassle.