Welcome to the World of Shine: A Comprehensive Guide to Plating for 3D Printed Jewelry

3D printing has revolutionized jewelry design, liberating creators from the constraints of traditional techniques and unleashing unprecedented geometric complexity. However, achieving a coveted metallic finish—a lustrous gold, a smooth silver, or a dazzling rose gold—often requires the magic of electroplating. This guide delves into the art and science of electroplated 3D printed jewelry, transforming your detailed prints from matte plastic masterpieces into shiny, durable metal ornaments.

Why electroplating 3D printed jewelry?

- Aesthetic changes: The initial charm! Achieve a true metallic look, from classic precious metals (gold, silver, rhodium, platinum) to trendy modern finishes (copper, brass, black nickel).

- Enhanced durability: Electroplating significantly improves the scratch and abrasion resistance of printed parts, which is critical for jewelry that is handled daily. It protects fine details.

- Improved feel and weight: The metal feels cool and solid. Plating adds desirable weight and quality feel ("Feel") that plastic lacks.

- Chemical resistance: Compared to bare plastic or resin, metal coatings offer superior resistance to skin oils, cosmetics, and environmental factors.

- Hypoallergenic options: The plating provides a biocompatible barrier, allowing sensitive individuals to wear potentially irritating materials using nickel-free plating such as palladium nickel or pure gold.

- Increase business value: Professional plated jewelry has a higher perceived value and marketability.

Understand the process: from printing to perfect plating

Electroplating uses an electrochemical reaction to deposit a thin layer of metal on a conductive surface. For non-conductive prints, key preparation steps are crucial:

-

print: Material selection is crucial. Common options:

- Photopolymer resin (SLA/DLP/LCD): It is widely used in making intricate jewelry. Avoid using soft, stretchy resins. Choose an engineering-grade resin known for its dimensional stability and post-cured robustness (e.g., tough, durable, ABS-like).

- FDM filament: PLA or ABS can be plated, but require extensive post-processing to eliminate layer lines. Not as ideal as resin for fine details.

- SLS Nylon: Excellent mechanical properties, but porosity requires more aggressive sealing/pretreatment. Popular for functional rings/bands that require strength.

- Key considerations: Smart design allows for easy disassembly without damaging functionality. Make sure to cure/post-process thoroughly according to material guidelines – uncured resin will affect adhesion. Minimize internal cavities that trap plating fluid.

-

Preparation after printing (vital!): This stage determines the success of electroplating.

- Supporting and sanding: Carefully remove all supports. Sanding starts with a coarse grit (e.g., 400 grit) to eliminate major printing lines/steps and then works your way up to very fine grits (800-1500+ grit) to achieve a smooth surface. Perfect smoothness is not initially required, but major imperfections will become apparent under the metal. Polish with compounds to meet higher gloss requirements.

- clean: Ultrasonic cleaning in a detergent solution removes polish residue, fingerprints and dust. Follow with a thorough rinse (deionized/reverse osmosis water preferred).

-

Make a surface conductive:

- Conductive Paint/Ink: Manually apply an aerosol or brush-on solution containing conductive particles (silver, graphite). Careful application is required for an even coating, often requiring multiple thin coats. Susceptible to polishing damage. Best for low volume/hobbyist applications.

- Electroless plating (recommended for professional results): An autocatalytic chemical process that deposits a thin layer of metal (usually copper or nickel) directly onto the part in a bath. This creates a uniform, highly adherent conductive base layer that is ideal for subsequent plating. Specific etching/activation steps are required prior to immersion.

-

plating: The workpiece (cathode) is immersed in an electrolyte solution containing the desired metal ions to be plated. An anode (usually made of electroplated metal) completes the circuit. Applying a direct current causes metal ions to be reduced and deposited onto the conductive surface of the cathode.

- Preprocessing: Acid soaking cleans the conductive layer and prepares it for bonding.

- Middle layer: Often essential! Depositing copper before silver or gold improves ductility and adhesion (copper is cheap). The nickel layer underneath the decorative gold/rhodium significantly improves the barrier properties against corrosion and diffusion of base metal/substrate elements. Palladium Nickel was a popular barrier/hypoallergenic choice before precious metals.

- Decoration layer: Final Finish: Gold (different carats/colors), Silver, Rhodium (bright white, protective), Palladium, Bronze, Brass, Black Nickel, etc.

- Key parameters: Voltage/current density, bath composition/concentration, temperature, soaking time, anode placement, and stirring all affect thickness, uniformity, brightness, and adhesion. Precise control is required.

- Post-plating treatment:

- rinsing: Thorough rinsing removes all plating chemical residue.

- Passivation: Especially for silver/silver alloys, chromate impregnation creates a protective oxide layer that reduces tarnish.

- Protective coating: Varnish (UV resistant) will minimize tarnish/fingerprints but will reduce the metallic shine. Plasma coating provides ultra-thin protection. Optional, depends on metal/duration expectations.

Key considerations and common challenges

- Adhesion failed: Usually due to inadequate surface preparation, contamination, substrate/resin incompatibility, incorrect etching/activation, excessive plating thickness/stress. Testing adhesion (tape testing) early in development is critical.

- Burning/high spots: Thin edges/details are subject to higher current densities, resulting in rough, dark deposits. Reduce voltage/current, improve stirring/anode geometry, add leveling agent to bath.

- Pitting/Porosity: Air bubbles remain on the surface during plating. Vigorous solution stirring helps prevent this.

- Uneven deposition: This may be caused by improper anode placement, insufficient stirring, or uneven conductivity on the substrate. Proper racking and tank design is critical.

- Resin Compatibility: Not all resins work well as catalysts. Conductivity and pore structure vary widely. New resins must be rigorously tested.

- Thermal sensitivity: Thermoplastic FDM parts may deform in a warm water bath. Bath temperature control is critical.

- Safety: Electroplating involves corrosive acids, bases, potentially toxic metals/metal salts, and flammable solvents. Proper PPE (gloves, goggles, respirator), fume extraction, and wastewater disposal (never pour down the drain!) are non-negotiable. Regulations vary widely from place to place.

Partnering with professionals: the key to continued excellence

Mastering in-house plating requires significant capital investment (specialized equipment, off-gas, wastewater treatment), expertise in chemistry and process controls, strict safety protocols, and ongoing maintenance. For designers, studios and businesses looking for a reliable, museum-quality finish without the overhead and liability, work with a professional plating service provider such as huge light is the optimal path.

Why GreatLight stands out in the field of electroplated 3D printed jewelry:

At Honlite, we are more than just printers; we are printers. We embody total manufacturing excellence. We know that your intricate 3D printed jewelry design deserves a finish that matches the precision and artistry that went into its creation. Leverage our extensive expertise in additive manufacturing and Metal surface treatment, we offer seamless One stop solution:

- Deep materials and process knowledge: Decades of experience plating complex prototypes across a variety of industries translate directly into producing flawless finishes on challenging resin geometries. We know which materials plate well and how to handle challenging shapes.

- Advanced plating line: We operate a state-of-the-art electroplating line with:

- Precision rectifiers and controllers enable consistent current density.

- Maintain a temperature-controlled stirred bath following strict analytical protocols.

- Dedicated production lines/stages for electroless nickel plating, functional electroplating (copper/nickel) and advanced decorative surface treatments (gold, silver, rhodium, palladium nickel, special alloys).

- Advanced racking solutions maximize throughput and minimize consumption.

- Superior electroless metallization: We utilize a proven electroless plating process to create a highly adherent, uniform conductive layer optimized for subsequent plating adhesion on complex SLA/LCD/DLP/SLS parts.

- Material Integrity Focus: We tailor our processes to protect the integrity of your design while paying attention to the resin’s specific sensitivities to chemicals and temperature.

- Dedicated control and quality assurance: Strict QC protocols ensure adhesion (ASTM B571 cross/scratch adhesion test), thickness (XRF measurement), corrosion resistance (ASTM B368 CASS/NSS test), solderability/appearance/color consistency. Provide certificate of conformity.

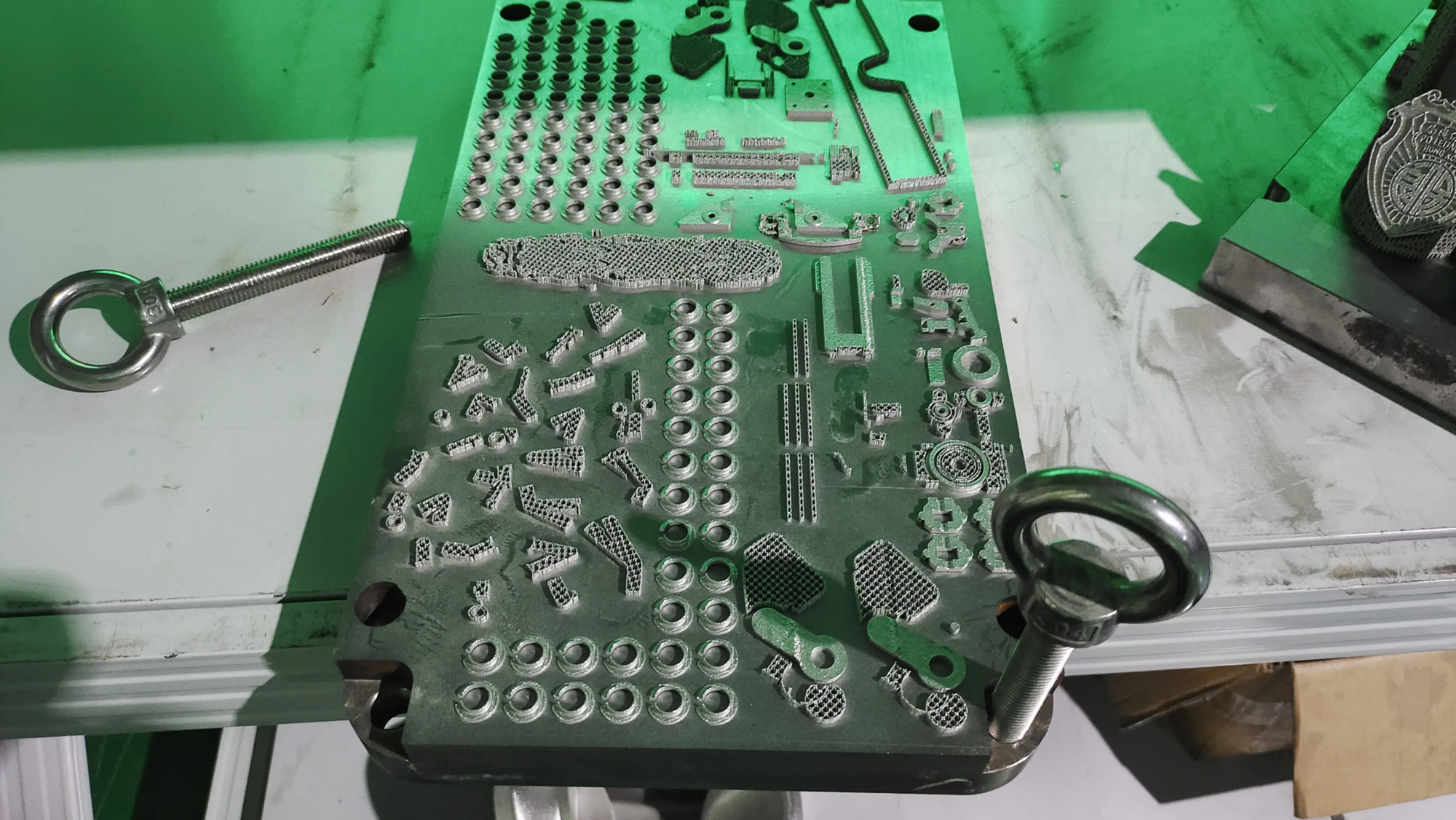

- Complete rapid prototyping backbone: Need a printout and plating? Our capabilities include advanced SLM printing and precision plating, ensuring optimal print settings to seamlessly meet plating requirements.

- Custom Finishes: In addition to standards, we specialize in achieving the unique finishes and effects required by cutting-edge jewelry designers.

- Scalability and reliability: Structured processes ensure consistent quality from batch to batch, from single prototypes to high-volume production.

- Safety and Responsibility: Implement strict environmental controls and handle plating chemicals responsibly.

in conclusion

Electroplating transforms 3D printed jewelry from a novel concept into long-lasting, luxurious wearable art. While achievable at a basic level by amateurs, the intricate requirements of jewelry require precise preparation and a controlled electrodeposition process to guarantee a stunning, durable finish. Understanding the science and challenges enables designers to optimize their prints for plating success.

For professionals requiring museum-quality results, consistent batch-to-batch perfection, complex finishes, or streamlined prototyping-to-finish workflows, partner with expert providers such as huge light Eliminate complexity and risk. Our advanced SLM printing capabilities, complemented by our advanced plating infrastructure and deep metallurgical expertise, enable us to be your true partner in bringing complex, beautiful finished jewelry concepts to market quickly and reliably. Embrace the brilliance – let GreatLight illuminate your designs with professional plating expertise.

Frequently Asked Questions (FAQ) – Electroplated 3D Printed Jewelry

-

able any Can 3D printing materials be electroplated?

- Although technically there are many able Plating after proper preparation, not all are suitable Used for jewelry plating. Castable resins are specifically designed for direct investment casting into metal. Standard SLA/DLP/LCD resins require proper preparation for electroless plating. Engineering/cosmetic resins (e.g. Somos/Tough/Durable resins) vary in plateability – testing recommended. Avoid using soft/flexible resins. FDM plastics (PLA/ABS) are less effective at plating than resin and do not require extensive sanding/sealing work. SLS nylon panels work well but require aggressive sealing/preparation.

-

How durable is resin plating?

- Durability is highly dependent on plating thickness, intermediate/base metal layers, resin quality/design, bonding quality and final plating type. Good quality plating on the right resin (with a proper nickel/copper underlayer) can last years of normal jewelry wear. Rhodium plating significantly improves the scratch resistance of softer metals. Thin decorative gold plating will wear off faster than thicker gold plating or nickel/ruthenium plating. FDM plating is generally less durable due to inherent porosity/texture.

- Is plating safe for people with metal allergies?

- It all depends on the plating choice. Nickel (especially nickel-based layers) is a common allergen. Compliant hypoallergenic plating stacks typically involve palladium-n