Bringing the Digital Battlefield to Life: A Comprehensive Guide to Halo Infinite 3D Printing and Modeling

The release of Halo Infinite has reignited the passion of countless Spartan and Covenant fans. In addition to the immersive gaming experience, it unleashes a burst of creative potential with stunning 3D models. Transforming these digital designs into tangible collectibles, cosplay pieces, or intricate display pieces has become an exciting pursuit for fans and makers alike. This guide takes a deep dive into the world of Halo Infinite 3D printing, covering everything from sourcing models to achieving a professional-quality finish, with a special emphasis on things like huge light Unlock amazing results.

Learn about the Halo Infinite 3D model

The journey begins with a digital blueprint. Halo Infinite features extremely detailed character models (Spartan, Elite, Barbarian), iconic weapons (M41 SPNKR, MA40 Assault Rifle, Energy Sword), vehicles (Warthog, Ghost, Scorpion Tank) and environmental assets. Thankfully, many of these models are accessible:

- Official source: While 343 Industries does not distribute game-ready print files directly, concept art and official renders inspire community creations.

- Community Market: Sites like Cults3D, Thingiverse, Printables, and MyMiniFactory are all treasure troves. Talented designers painstakingly recreate game assets, often optimized for 3D printing. search "Halo infinite," "Mk VII armor," "needle punching machine," ETC.

- Professional modeling website: Platforms like Gambody occasionally offer high-detail, professionally modeled Halo theme kits.

- Model extraction: (Advanced/Warning!) Tools exist to extract models directly from game files. However, this often involves complex cleanup in CAD software (Blender, MeshMixer) to make them printable, and requires ethical considerations regarding asset use. Make sure to comply with the terms of service.

Key considerations when choosing a model:

- Purpose: Is it a small tabletop toy, a detailed scale model, or wearable armor? The size determines the level of detail and printing method.

- complex: Evaluate the geometry of the model. Complex designs such as detailed armor or energy weapons often require careful slicing and support strategies.

- File format: Make sure the model is in a printable format (STL or OBJ are common).

- optimization: Look for models that come pre-supported (saves slicing time) or pre-sliced. Clearly marked model number "Printable" Factors such as built-in wall thickness often need to be considered.

- scale: Verify the dimensions of the model. Rescaling can significantly affect printability and detail.

Master the printing process for Halo creations

Transforming digital Spartan into physical reality requires careful planning:

- Software settings: Use powerful slicing software such as Ultimaker Cura, PrusaSlicer, or Lychee Slicer (for resin). They convert your STL into printer-readable instructions (G-code).

- direction: Strategically positioning the model can minimize supports on critical surfaces and reduce visible layer lines. For armor components, vertical orientation generally produces the best exterior surface finish.

- support: Halo models, especially with overhanging weapons or grooved armor, will always need support. Use organic/tree supports in software wherever possible to reduce contact traces and material usage. Fine-tuning support density and contact point size is critical.

- Floor height: For FDM (filament) printers, 0.1 – 0.2 mm layers capture finer details. Resin printers are inherently good at detail, but require meticulous post-processing.

- Material selection: This heavily affects the final look and feel:

- People’s Liberation Army: Default Selection – Easy to print, available in countless colors (including Halo-themed metallics!). Ideal for displaying models and larger armor pieces.

- Polyethylene glycol: Tougher and more heat-resistant than PLA, ideal for functional parts or props that are frequently handled.

- ABS/ASA: Excellent durability and temperature resistance, but requires housing and careful ventilation; ideal for long-lasting role play elements.

- Resin (SLA/DLP): Unparalleled detail, perfect for miniature Spartan warriors, infantry soldiers, complex weapon assemblies or highly detailed helmet displays. Requires isopropyl alcohol for cleaning and curing.

- Nylon/Carbon Fiber: For extremely durable functional parts (hinges, moving mechanisms). Harder to print.

- Print calibration: Ensure bed is flat, optimal temperature, extruder calibration and retraction settings to prevent stringing and spotting. For complex Halo models, a well-tuned printer is crucial.

The art of post-processing: from print to masterpiece

Original prints rarely capture the full appeal of Halo designs. Post-processing improves them:

- Support removal: Carefully remove the supports using flat nose pliers, pliers and a file.

- clean: For resin prints, they must be thoroughly cleaned in IPA and UV cured. Clean dust/dirt from FDM parts.

- Polishing: Mastering the sanding process (starting with about 120 grit and gradually finer to about 600-2000 grit) can smooth out layer lines. Wet sanding helps prevent the plastic from overheating.

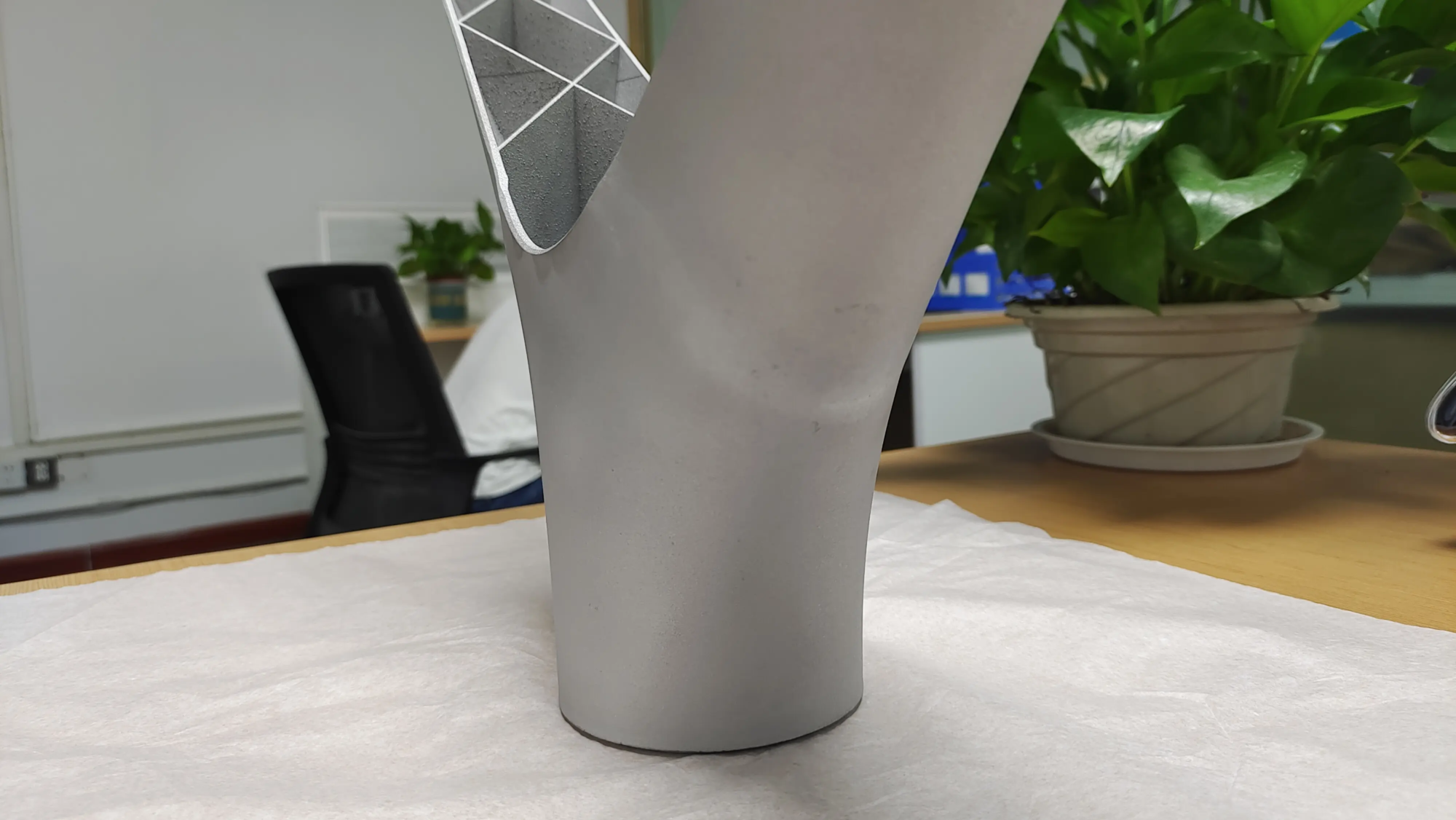

- Gap filling: Use filler primer, epoxy putty (Milliput), or spot putty to fill layer lines, support scars, and gaps between assembled parts. Then smooth it with sandpaper.

- Primer: Use a high quality primer (spray can or airbrush) to create an even surface and reveal imperfections that require more filling/sanding.

- painting: This is where your creation comes to life:

- Primer: Acrylic model paint is preferred. Use a spray gun to get smooth surfaces and large surfaces.

- Detail work: hand-painted badges, intricate patterns, weathered effects and LED integration points.

- Weathering: Techniques such as dry brushing, washing (panel lining) and chipping add realism.

- assembly: Use CA glue (superglue) to glue components for quick bonding, epoxy for strength, or mechanical fasteners for durability (especially for cosplay). Magnets are great for modular armor.

- Finishing touches: Varnish (matt, satin, gloss) protects the paint surface and provides the desired final shine. Consider specialized metal plating services for your iconic energy sword.

Accelerating excellence with expertise: The GreatLight advantage

While DIY printing offers great satisfaction, the real Professional-grade, durable metal replicas – Especially for complex designs or demanding applications – where advanced functionality is required. where is this huge light Sparkling.

as a leader rapid prototypingGreatLight utilizes state-of-the-art technology Selective Laser Melting (SLM) 3D Printing technology. SLM creates strong, high-density metal parts directly from powder, making it ideal for:

- Metal Weapon Replicas: Print intricate energy sword hilts, detailed BR75 receiver components or durable armor pieces using materials like stainless steel, titanium or aluminum alloys.

- Highly detailed character logos: Tiny yet intricate symbols are rendered in gleaming metal.

- Functional components: Parts requiring structural integrity (mechanisms within scale vehicles, durable armor clips/buckles).

- Main mode: Create extremely detailed metal masters for cast replicas.

In addition to printing, GreatLight’s one-stop-shop services include critical post-production:

- Expert support for removal: Remove carefully, minimizing stress on delicate metal parts.

- Precision grinding and polishing: Achieve a mirror gloss or controlled satin/matte finish on metal surfaces.

- Advanced surface treatment: Includes sand blasting, close tolerance CNC machining, electroplating (chrome, gold, nickel), intricate engraving or custom patina.

- Heat treatment: Enhanced material properties for increased strength and durability.

- Quality inspection and assurance: Ensure size and integrity meet strict standards.

GreatLight leverages proven production workflows and materials science expertise to provide fast turnaround and competitive pricing for custom metal parts. Whether you need a metal energy sword core, a titanium Spartan badge, or an aluminum MA40 component, their team of professionals can efficiently solve complex prototyping challenges. Explore their abilities and improve your Halo creations: [Link to GreatLight’s Service Page – Customize your precision Rapid Prototyping parts now at the best price!]

Conclusion: Build your legacy

3D printing opens an exciting portal to owning tangible parts of the Halo universe. From sourcing or creating models to tackling complex printing issues and mastering post-processing, the entire process makes sense. Tackle DIY projects can build skills, but keep in mind that getting a museum-quality metal replica or an ultra-durable functional cosplay piece will often benefit greatly from professional rapid prototyping services. company likes huge lightWith advanced SLM printing and comprehensive post-press expertise, creators are able to push boundaries and realize their visions of unparalleled quality and durability. So, get ready, Spartan! Your next iconic Halo Infinite masterpiece is waiting to be created.

FAQ: Halo Infinite 3D Printing

-

Q: Are there any legal issues with printing Halo Infinite models?

Answer: Printing is used for Personal use/non-commercial display Generally considered acceptable under fair use and tolerated by the community/platform hosting the file. Selling Printed Models Building directly on extracted game assets or copyrighted designs without the express permission/permission of Microsoft/343 Industries is illegal and infringes copyright. Ethical sourcing from creators who offer licensing models is critical to commercial sales.

-

Q: What is the best Halo model for beginners to print?

Answer: Start small! Highly rated, pre-supported community models such as "Hybrid car chip" (Cortana), a simple BR75 receiver detail, a basic grunt head, or a simple badge/emblem are all great options for practicing bracing and finishing before tackling a complex armored helmet or vehicle.

-

Q: FDM vs. Resin: Which is best for Halo printing?

Answer: It depends on:

- Frequency division multiplexing: Best suited for larger parts (armor, helmets, warthog parts) due to cost effectiveness, material strength/variety and size capabilities. More post-processing is required to obtain a smooth surface.

- Resin: It’s unparalleled for the miniature Spartan/Covenant figures, intricate weapon details like ammo counters/sights, and the highly detailed small helmet (for display). Requires extensive post-processing (cleaning/curing) and can be brittle.

- Q: How do you make 3D printed armor tough enough for cosplay?

Answer: Use elastic materials such as PETG, ABS or reinforced wire (nylon/CF). Increase wall thickness/girth and infill density (15-25%+ for larger pieces). Reinforce internal high stress areas using fiberglass resin/epoxy coatings