Hat Brims and Skirts: The Ultimate 3D Printing Bed Bonding Guide

Struggling with warped prints, corners lifting off the build platform, or an inconsistent first layer? you are not alone. Bed adhesion remains one of the most common challenges in 3D printing, especially with materials that easily heat shrink, such as ABS, nylon or polycarbonate. Two powerful tools –edge and skirt– Work hard to solve these problems. While they may look similar at first glance, understanding their unique features and best applications is critical to printing success.

What is a hat brim?

The brim is one Flat, horizontal extension Extend outward from the edge of the first layer of the model. Unlike a raft (a raft is located in below print) with the edge attached directly to the bottom of the part. it works like a "welding," Secure the edges securely to the build platform plate.

How it works:

- Increase surface contact area Between the print and the bed.

- Disperse the internal stress generated by cooling to prevent warping.

- Acts as a thermal insulator to maintain a stable temperature around the print.

When to use a hat brim:

- print narrow and tall objects (vases, towers).

- Small footprint model (<5 cm² base area) Features critical edge detail.

- High warpage risk materials (ABS, nylon, PC).

- Bottom printing scar removal is not a critical issue.

Pros and cons:

- ✅ Advantages: Excellent warpage resistance and improved bed bonding strength.

- ❌ Disadvantages: May leave visible scars on the edges of the print with extra material.

What is a skirt?

A skirt is one or more pieces Print outline around print object No touch it. Its main purpose is preparation: Start the nozzle and stabilize the extrusion flow rate forward Actual printing begins.

How it works:

- Ensure smooth material flow by removing residue or inconsistent filaments.

- Help with leveling verification: Visualize nozzle height irregularities.

- Minimal thermal impact: Prints can be framed without heat binding.

When to use skirts:

- Reliable PLA printing Covers a large area (>10 cm2 base).

- Printing requirements Clean edges, no post-processing required scar.

- need situation Only the flow is stable (e.g. after nozzle pause).

Pros and cons:

- ✅ Advantages: Less material waste, easy disassembly, and convenient nozzle filling tool.

- ❌ Disadvantages: Zero anti-warping benefit.

Hat brim vs. skirt: main differences

| feature | edge | skirt |

|---|---|---|

| Contact Printing | Touch model edge | No connection with the model |

| Purpose | Enhance adhesion | Nozzle Prime/Flow Check |

| Prevent warping | high | without any |

| Materials used | Medium/High (approximately 3–5% extra) | Minimal (1-2 cycles) |

| Post-processing | Needs trimming/scarring | without any |

| most suitable material | ABS, nylon, PETG, PC | PLA, TPU, wooden PLA |

Advanced tips and techniques

- Adaptive brim: For complex bottom geometries (non-linear edges), gently increase "brim width" or use "Only inside the brim" (in microtome like Cura) to avoid scarring in visible areas.

- Filament and edge tolerances: Materials and <0.1mm shrinkage difference (e.g. PETG) Edge width 5-8 mm works well. High shrinkage alloys and composites (carbon fiber-nylon) require 10-15 mm.

- Span edge: Use skirts with localization when printing large parts that require mobility but low warpage "mouse ears" (Manually place the small rounded edges below the corners).

- Temperature adjustment: Matching hat brim +5–10°C bed temperature offset In the first 15 layers, especially for builds prone to warping.

Conclusion: The method matches the task

When fighting shrinkage-driven separation, edges are your ally, especially with engineering-grade metals or high-temperature polymers. Skirts perform well in priming tasks or prints where aesthetics outweigh the risk of adhesion. Remember: Proper bed adhesion strategy depends on the physical properties of the filament and the fragility of the geometry.

Why choose Gretel Precision Printing?

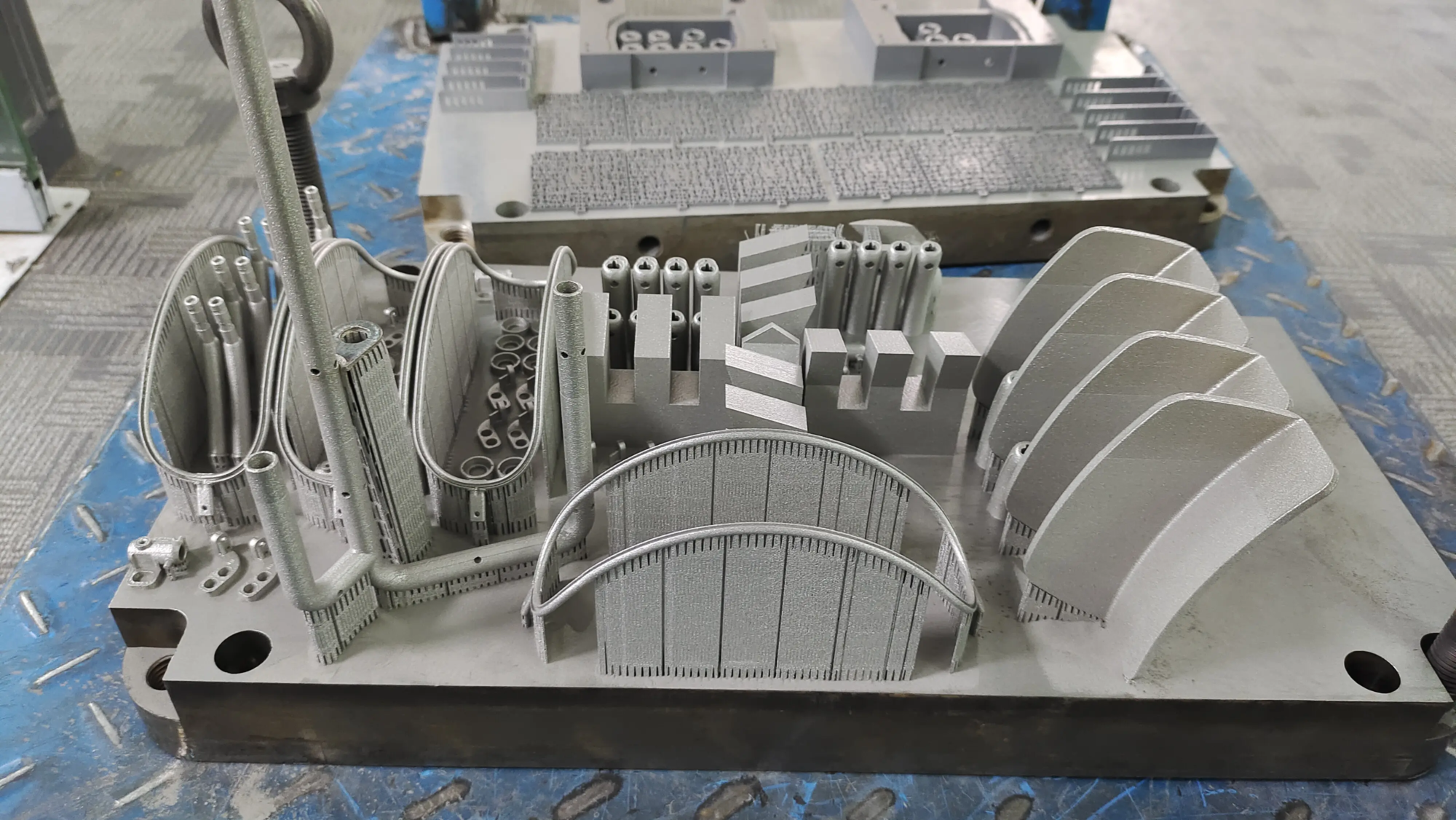

exist huge lightwe combine expertise in industrial-grade selective laser melting (SLM) systems with deep materials science insights. As a leader in rapid prototyping, we specialize in Metal parts manufacturing Utilize advanced bed adhesion strategies tailored for high-performance alloys. Whether you need titanium aerospace prototypes or copper-nickel thermal parts, our end-to-end services, from slice optimization to HIP post-processing, ensure warp-free results.

Experience the GreatLight advantage: custom precision-engineered parts with turnkey finishing at competitive prices and guaranteed dimensional accuracy.

FAQ: Hat brims, skirts, and more

Q1: Can I combine the brim/skirt with the raft?

Rarely constructive. Raft essentially adds a sacrificial layer underneath the part, eliminating the need for gluing. Adding edging to the roof of your raft just wastes material.

Question 2: Will edges ruin the detail of a miniature print?

There is potential. For miniatures (e.g. tabletop statues) please use <4mm edges and trim with a heated flat cutter. Or, switch to PEI/texture board for enhanced grip without the need for additives.

Q3: How to optimize skirt parameters?

put 2–3 skirt lines 0.2–0.5mm clearance from printed matter. If extruder bounce occurs after cleaning on a long print, increase the number of cycles.

Q4: Why does the brim of my hat turn up?

Insufficient edge adhesion means:

- Unbalanced bed leveling (recalibrate!)

- Filament contamination (clean plate with IPA)

- Uneven cooling – add crust.

Q5: Is the brim/skirt related to the resin printer?

greatly reduced. Resin printers rely on peeling force, not thermal stress. "Manual brim" (raft base) helps increase suction resistance – enabling automation in applications like Lychee Slicer.