The critical role of 3D printer size in helmet manufacturing: a comprehensive guide

In the rapidly growing field of additive manufacturing, creating functional helmets—whether for aerospace, motorsports, medical safety, or apparel design—comes with unique challenges. Unlike smaller components, helmets require exceptional precision, material durability and, most importantly, Sufficient build volume. Since the helmet exceeds typical print bed dimensions, understanding 3D printer size limitations became critical. At GreatLight, we use cutting-edge large-format 3D printing to overcome these obstacles and provide industrial-grade solutions for complex helmet projects.

Why Size Matters: Helmet Printing Challenge

Modern helmets are more than just aesthetically pleasing pieces; They are engineered for impact resistance, ergonomic comfort and weight optimization. Standard adult helmet required Minimum build volume 300 x 300 x 350 mmbut larger designs (such as motorcycle or space helmets) may exceed 500 mm in diameter. Standard desktop printers typically have a maximum size of 250 mm³, forcing users to split the design into multiple parts. This creates weak joints, increases post-processing labor, and compromises structural integrity. Large format industrial printers eliminate these trade-offs by enabling Single piece production.

Helmet 3D printing technology

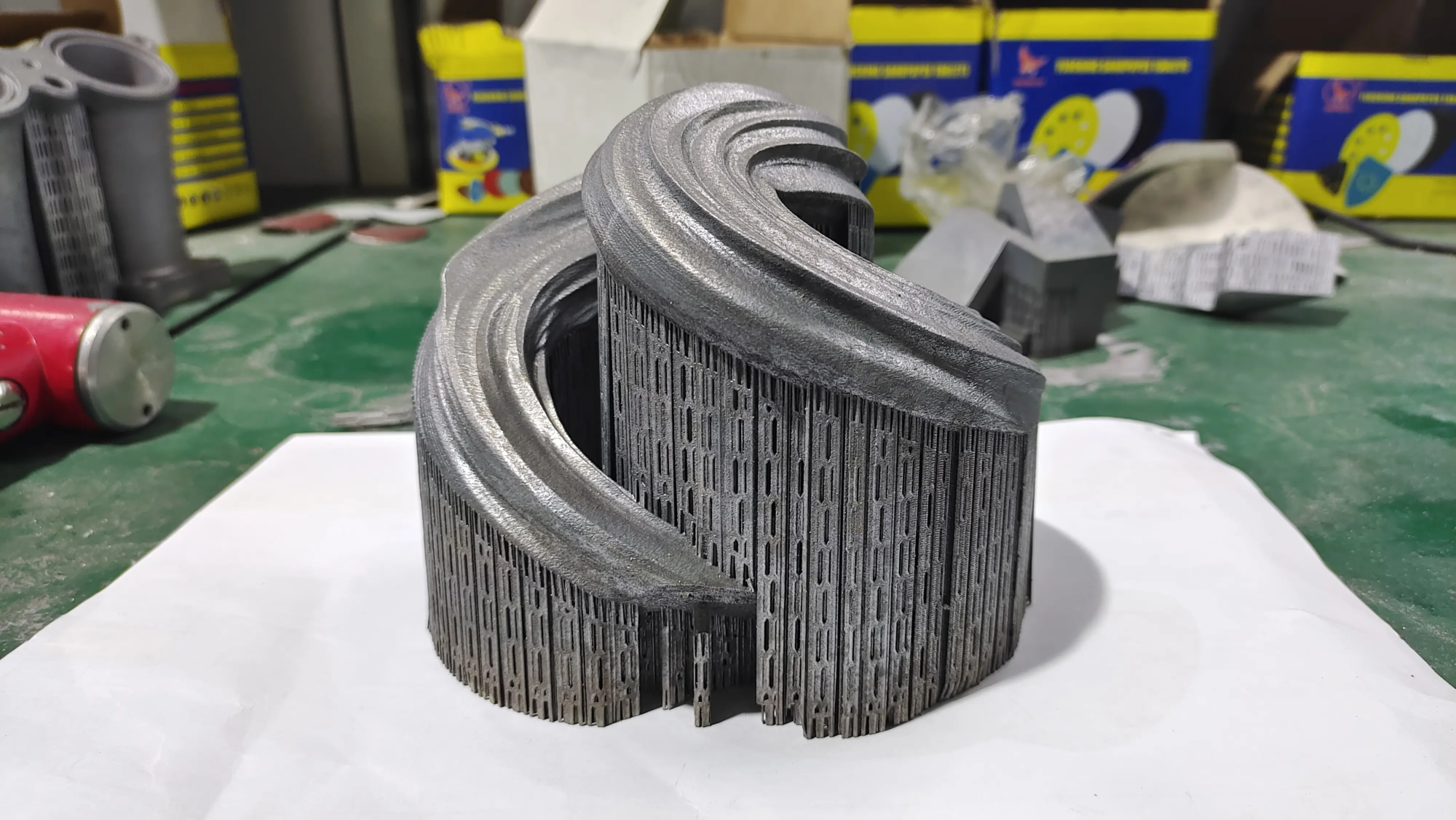

- FDM (Fused Deposition Modeling):

Ideal for low-cost prototyping using thermoplastics such as ABS or PETG. However, layer lines and size limitations make it unsuitable for a final functional helmet unless printed in sections. - SLA/DLP (stereolithography/digital light processing):

Ideal for high-resolution cosplay or medical helmets using resin. Build volumes are often limited to single-piece printing, requiring assembly. - SLS (Selective Laser Sintering):

Use powder materials (nylon, TPU) to create strong, flexible parts. Industrial SLS systems can handle larger helmets, but have difficulty handling fine surface finishes. - SLM (Selective Laser Melting):

Our specialty at GreatLight. Metal helmets (aluminum, titanium, Inconel) used in aerospace or defense require the precision and strength of SLM. We deploy the printer 1,000 x 600 x 500 mm volumeenabling full-size, single-print manufacturing.

Beyond Dimensions: Materials Science and Engineering

Size alone is not enough –Material selection determines performance:

- thermoplastic It’s lightweight for a sports helmet, but the thickness needs to be optimized to absorb impact.

- metal alloy (Printed via SLM) Provides an unparalleled strength-to-weight ratio for extreme environments.

- mixed methods Combine printed structures with composite linings such as Kevlar-infused upholstery.

Our engineers perform topology optimization to reduce weight without sacrificing durability and ensure compliance with ISO or ASTM safety standards. Post-processing (heat treatment, polishing, coating) further enhances functionality.

Gretel’s Capabilities: Creating Large-Scale Solutions

Features of our facilities Industrial SLM Printer Build volumes up to 800 mm³ with multi-jet fusion and SLA systems. This allows us to:

- Print full size aviation helmets within 24/48 hours.

- Achieving ±0.1 mm tolerance and seamless integration with visor/pad.

- Scale prototypes to volume production with tool-free manufacturing.

Customers can get one-stop service including HEM (Hybrid Additive Manufacturing) Used to embed electronics or cooling channels into designs.

Case Study: Customization Simplified

A Formula 1 team requires 20 titanium helmets with integrated cooling ducts. Our workflow:

- Used SLM printed titanium frame (single piece; 550 mm high).

- Incorporating the airflow grid structure, the weight is reduced by 35%.

- Sandblasted and heat-resistant coated.

Total delivery time: 4 days compared to 3 weeks using traditional methods.

Conclusion: Helmet production for the future

3D printer dimensions are the basis for helmet innovation. One-piece printing eliminates weak points, speeds up production, and unlocks complex geometries previously unachievable through molding or subtractive methods. At GreatLight, we combine massive production volumes with SLM expertise to deliver end-use helmets that are safer, more customizable and faster than traditional alternatives. Whether prototyping or large-scale production, our solutions combine scientific precision with boundless creativity.

FAQ: 3D Printed Helmets

Q1: Can you print a complete helmet?

Yes – with industrial printers. We use SLM and SLS machines (500–800 mm build volume) for monolithic printing. Desktop printers require segmented design.

Question 2: What materials are best for safety-critical helmets?

Metals (titanium/aluminum) via SLM for impact resistance, or engineering polymers (PEKK, nylon) via SLS for lightweight applications. Material selection depends on certification requirements.

Q3: How do you handle interior padding/ergonomics?

We use topology optimization software to design hollow structures with lattice filling. The foam/padded cavities are integrated and pre-printed ensuring weight distribution and comfort.

Q4: Are 3D printed helmets as safe as traditionally manufactured helmets?

Yes, when printed using industrial equipment (ISO certified processes), rigorously tested and properly coated/finished. Post-processing eliminates porosity and ensures uniform density.

Q5: How long does it take to print a full-size helmet?

Systems using GreatLight:

- SLM (Metal): 24–72 hours

- SLS (polymer): 12–36 hours

Delivery times vary based on complexity, size and post-processing.

Q6: Can I print using a combination of materials?

In a single print, SLM/SLS is a single material. However, we assemble hybrid components after printing (e.g., metal shell + polymer liner using industrial adhesive).

Customize your project with GreatLight’s qualified engineers – supporting over 100 large-format industrial 3D printers and full spectrum post-processing. Submit your CAD files for same-day quotes and fast precision manufacturing. Contact our team →