Flying without limits: How 3D printing is revolutionizing DIY drone creation

Ever looked up at a drone in the sky and thought, "I wish I could build one exactly I imagine"? Forget about ready-made constraints and generic frameworks. The era of truly personalized, high-performance DIY drones has arrived, driven primarily by: Advanced 3D printing technology. This isn’t just plastic trinkets; we’re talking precision-engineered metal parts capable of withstanding serious aerodynamic forces and unleashing unprecedented design freedom. This is where professional rapid prototyping services become your essential co-pilot.

Why DIY? Beyond commercial off-the-shelf (COTS) drones

While prefabricated drones offer convenience, they inherently limit creativity and adaptability:

- Limited customization: Fixed layouts rarely accommodate the unique sensor payload, larger battery, or custom camera setup you need.

- Performance platform: Generic designs often use heavier materials or lack aerodynamic optimization for specific tasks such as endurance racing or ultra-efficient mapping.

- Maintenance troubles: Destroy proprietary arm or housing? Finding exact replacements can be expensive and time-consuming.

- Innovation bottleneck: Testing new aerodynamic concepts or novel gimbal mechanisms requires flexible manufacturing that is not possible with traditional methods.

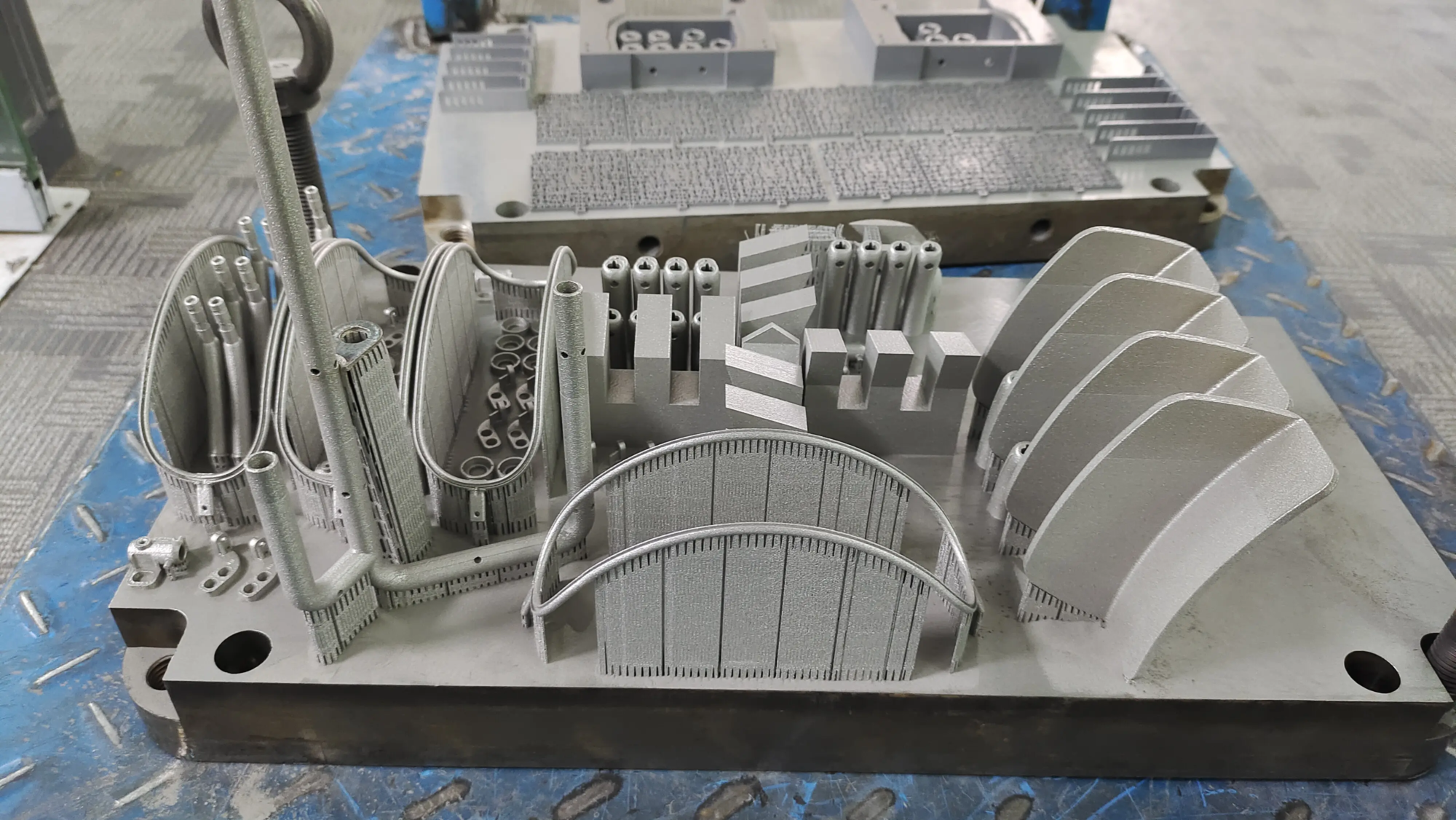

3D printing: Redefining your drone workshop

Enter Additive Manufacturing (AM), specifically Selective Laser Melting (SLM) and high-precision metal 3D printing. This technology transforms complex digital designs layer by layer into powerful physical realities, opening doors that are simply not possible with machining or injection molding:

- Unleash complex geometries: Creating organic shapes, internal cooling channels for agricultural engines, lightweight honeycomb structures, integrated cable routing paths and aerodynamic fairings that would not have been possible using subtractive methods.

- Complete weight loss: Topology optimization algorithms combined with metal powder bed fusion such as SLM enable designers to remove only structurally unnecessary material, creating extremely strong yet thin components critical to flight performance. Consider optimized motor mounts, custom camera housings, and chassis mounts.

- Accelerate design iterations: From CAD concept to functional prototype skynot weeks. Test mount the motor mounts, crash test the landing skid, adjust the aerodynamic profile, then reprint in no time. Rapid iteration significantly reduces development risk and cost.

- Material mastery: Direct access to aerospace grade materials.

- Aluminum alloy (AlSi10Mg, Scalmalloy®): Excellent strength-to-weight ratio, good thermal conductivity (for motor/battery heat dissipation), widely used in lightweight frames and structural parts.

- Titanium alloy (Ti6Al4V): Excellent ultimate strength, excellent corrosion resistance and biocompatibility. Suitable for the highest stress components such as critical joints and propeller adapters that require fatigue resistance.

- Stainless steel (316L, 17-4 PH): It has high strength, excellent corrosion resistance and good ductility. Durable housing and mounting bracket for harsh environments.

- Nickel alloy (Inconel series): Excellent high temperature performance is critical for hot operating systems or special applications. Unless absolutely necessary, this can be costly.

- Mass customization: Easily produce one-off custom parts or low-volume parts without costly mold changes. Each drone can be truly unique.

Designing for Airborne Success: Key Considerations

Printing drone parts isn’t magic. Success depends on smart design:

- Orientation question: Part orientation during printing can significantly affect surface finish, strength (especially vertical strength) and required support structure. Always design with printability in mind.

- Note the anisotropy: Metal AM parts exhibit anisotropic properties (strength changes depending on direction). Layout critical load paths and parallel analysis of major build directions or corresponding designs.

- Support strategy: Overhangs require supports, which must be carefully designed and removed after printing without damaging the part. Minimized supports speed up printing and finishing.

- Wall thickness and details: Criticism is everywhere. The minimum achievable thickness depends on the material/printer capabilities. Complex features approaching the resolution limit require careful evaluation. Gussets, fillets, and chamfers are great for adding strength and relieving stress.

- Vibration is the enemy: The drone vibrates significantly. Lightweight printed metal structures must be designed to suppress harmful resonant frequencies. Stiffness optimization is crucial.

GreatLight: Your dedicated manufacturing partner for high-performance drones

Transforming an ambitious drone project from a CAD file to a flight-ready metal reality requires more than just a printer. it takes manufacturing mastery. This is where GreatLight excels in rapid prototyping:

- Precision metal additive manufacturing expertise: Our core competitiveness lies in Advanced SLM technology. We have a deep understanding of optimizing laser parameters, powder properties, build chamber atmosphere, and thermal management to achieve repeatable, high-density (>99%) parts with superior mechanical properties.

- Deep materials knowledge: We work closely with you to select the best metal powder based on your drone’s specific needs.

- Balanced performance: AlSi10Mg is recommended for most structural frames where lightness and stiffness are required; titanium is recommended for ultimate strength where weight allows; stainless steel is promoted where durability is critical.

- Material certification: Ensuring consistent, traceable material quality is critical for flight-critical components.

- Engineering post-processing: Original prints are not suitable for flying. glow offer Integrated high-intensity finishing:

- Support removal: Careful technique can prevent damage to parts.

- Stress Relief and Heat Treatment: Essential for achieving specific material properties (e.g. annealing of AlSi10Mg, solution treatment and aging of Ti6Al4V).

- CNC machining integration: Precise finishing of mating surfaces, holes, threads – ensure perfect tolerance compliance with Haas 5-axis machining for error-free assembly.

- Surface enhancement: Vibration smoothing, sandblasted, anodized (aluminum), electrochemically polished to improve fatigue life, aesthetics and weather resistance.

- Design for Additive Manufacturing (DfAM) Collaboration: Our engineers don’t just print; They proactively analyze your STL/STEP files. We proactively flag potential printability issues (unsupported spans, thermal distortion risk), recommend topology optimization to reduce weight, and recommend directions/updates to minimize cost and improve manufacturability forward Printing starts.

- Speed and scalability: True rapid prototyping isn’t just about printing quickly; This is an optimized workflow from quote to shipment. GreatLight streamlines the process for rapid turnaround of prototypes (critical projects can take less than 7 days) and facilitates a seamless transition to low-volume production as your design matures.

Conclusion: Fly higher with custom manufacturing

3D printing, especially advanced metal additive manufacturing services like those offered by GreatLight, is not only changing the construction of drones, but also how they are manufactured. It is democratizing aerospace-grade manufacturing and empowering innovators. You are no longer limited by the drone manufacturer’s catalog. Whether you are pushing the boundaries of racing drone aerodynamics, designing a long-range heavy-duty VTOL platform, or crafting specialized sensor pods for agricultural mapping, metal additive manufacturing can bring unparalleled design freedom and performance optimization. By partnering with an experienced rapid prototyping service provider with real manufacturing expertise (EAT), you gain a valuable ally. From expert material selection and DfAM guidance, to precision printing and meticulous post-processing, GreatLight provides the strong, precision-crafted metal components you need to confidently launch your unique terminal drone vision into the sky.

Frequently Asked Questions (FAQ): Metal 3D Printing for DIY Drones

- Q: Are metal 3D printed parts strong enough for drones?

- one: Of course, if designed correctly and produced on a high quality SLM printer like ours. Aerospace alloys such as titanium (Ti6Al4V) and aluminum (AlSi10Mg) have strength-to-weight ratios that exceed those of many conventionally machined components. Correct design (orientation, support, topology) combined with optimized printing and post-processing (heat treatment) ensures excellent performance.

- Q: How lightweight can printed metal parts be to truly significantly reduce the weight of a bookstore?

- one: The weight reduction is significant. Topology optimization only removes material in non-critical areas. SLM parts can be 20-50% lighter than traditional machined parts (starting from bar stock) Have equal or better strength. Every gram saved has a direct impact on flight time, acceleration and payload capacity.

- Q: Can I design complex internal structures for cooling or wiring integration?

- Answer: Yes! This is a core advantage. Metal additive manufacturing excels at creating complex internal channels or integrated wiring paths for motor cooling airflow, greatly improving internal tidiness, mechanical integrity, aerodynamics, and reducing drag compared to external routing cables. Design these features directly into your CAD model.

- Q: What knee accuracy/tolerance can be achieved when printing drone parts?

- one: SLM printing typically achieves dimensional tolerances in the range of ±0.1 mm (±0.004 inches) on smaller features and structures. Crucially, critical mating surfaces (for motors, bearings, PCBs) often require CNC machining as part of post-processing services to ensure a perfect fit. GreatLight seamlessly integrates machining into finishing workflows.

- Question: I am new to CAD design. Can GreatLight help with the design phase?

- one: We strongly encourage it! While we do not typically replace design agencies (although we work with many), our DfAM engineers are heavily involved in technical reviews. We provide valuable feedback citation period Directional recommendations on manufacturability, potential design weaknesses, strength/surface finish of different parts, smart support structures, and weight reduction opportunities – significantly reducing the risk of print failure or later redesign. Share your CAD early to maximize your success.

- Q: Can you simulate vibration patterns?

- one: While GreatLight prioritizes excellence in physical prototyping, complex structural vibration/pressure/crash simulations are outside our core service scope. These tasks are best handled by professional CAE or FEA software (such as ANSYS, SimScale) used by design engineers prior to prototyping. However, noise extrapolation using our material property data and design recommendations regarding geometry/stiffness can help build a more vibration-resilient component.

- Q: What is the typical turnaround time for a set of drone frames/components?

- one: Turnaround time varies based on complexity, size, volume, post-processing required and current workload. For standard aluminum prototypes requiring CNC finishing/annealing printing, 8-12 working days Generally it is feasible. For titanium alloys or complex designs requiring lengthy heat treatments, Usually takes 12-16 working days+. Rush service may be available – ask directly after quote. hand avoidance "fire drill";Optimized scheduling ensures unparalleled reliability.

- Q: How does the cost compare to carbon fiber or CNC machining?

- one: Cost structures vary widely:

- Carbon fiber: Lower unit costs when producing high volumes (>100 parts). High tooling costs hinder prototype/low-volume production. Excellent strength/weight, but limited design freedom.

- CNC machining: Competitor for simpler geometries, efficient in achieving sharp tolerances Ready out of the box. Becoming expensive/cumbersome/too much material to remove twist constraints appears (and simply impossible with limited internal complexity).

- Metal SLM printing: When mass produced, the cost per part may be higher than CNC/carbon fiber today. However, it provides unparalleled value for prototyping, complex geometries (shapes that cannot be machined), one-time customization, lightweight optimized structures, accelerated iterations and proven design speed with negligible amortization of the required “big bang tooling” startup costs. Assessment includes: Design freedom → Productivity acceleration takes precedence over material savings and innovation support! TCO has earned recognition, and future workflows aim to conduct a more in-depth analytical benchmarking of lost overall project delays.

Ready to turn your vision into an aerial reality?

Don’t let manufacturing limitations hinder your aviation ambitions. Take your DIY drone project beyond the ordinary by leveraging GreatLight’s advanced SLM metal 3D printing capabilities and deep prototyping expertise to create high-performance, lightweight components. Experience the precision, creativity and speed of professional rapid prototyping. **[ExploreGreatLight’sCustomPartCapabilitiesToday&[立即探索GreatLight的定制零件功能&[ExploreGreatLight’sCustomPartCapabilitiesToday&