Modern Sealing Art: Using 3D Printing to Create Timeless Wax Seals

For centuries, wax seals have symbolized elegance, authenticity and personalization – adorning royal decrees, wedding invitations and precious letters. Today, 3D printing is breathing new life into this ancient craft, enabling complex customization with unprecedented speed and precision. This guide explores how 3D printing is revolutionizing wax seal creation, transforming digital designs into tangible heirlooms.

Why choose 3D printed wax seal?

Traditional seal production involves hand-engraving brass molds or CNC machining, which is often costly for custom designs. 3D printing removes these barriers:

- Unlimited customization: Transform your logo, monogram or illustration into a unique seal.

- speed: Transform digital files into functional stamps in hours, not weeks.

- complex: Achieve complex geometries impossible to achieve by hand engraving.

- Cost effectiveness: Ideal for small batches (e.g. weddings, events, branding).

Technology Spotlight: From Pixels to Sealing Wax

Although the wax itself cannot be printed directly through standard processes, advanced rapid prototyping technology can perfectly produce seal – Tools for printing wax. The main methods include:

-

Stereolithography (SLA):

- Create high-resolution stamp masters using UV-curable resin.

- Ideal for complex patterns with detail accuracy <50μm.

- Post-processing includes thermal curing and wax-resistant metal plating.

-

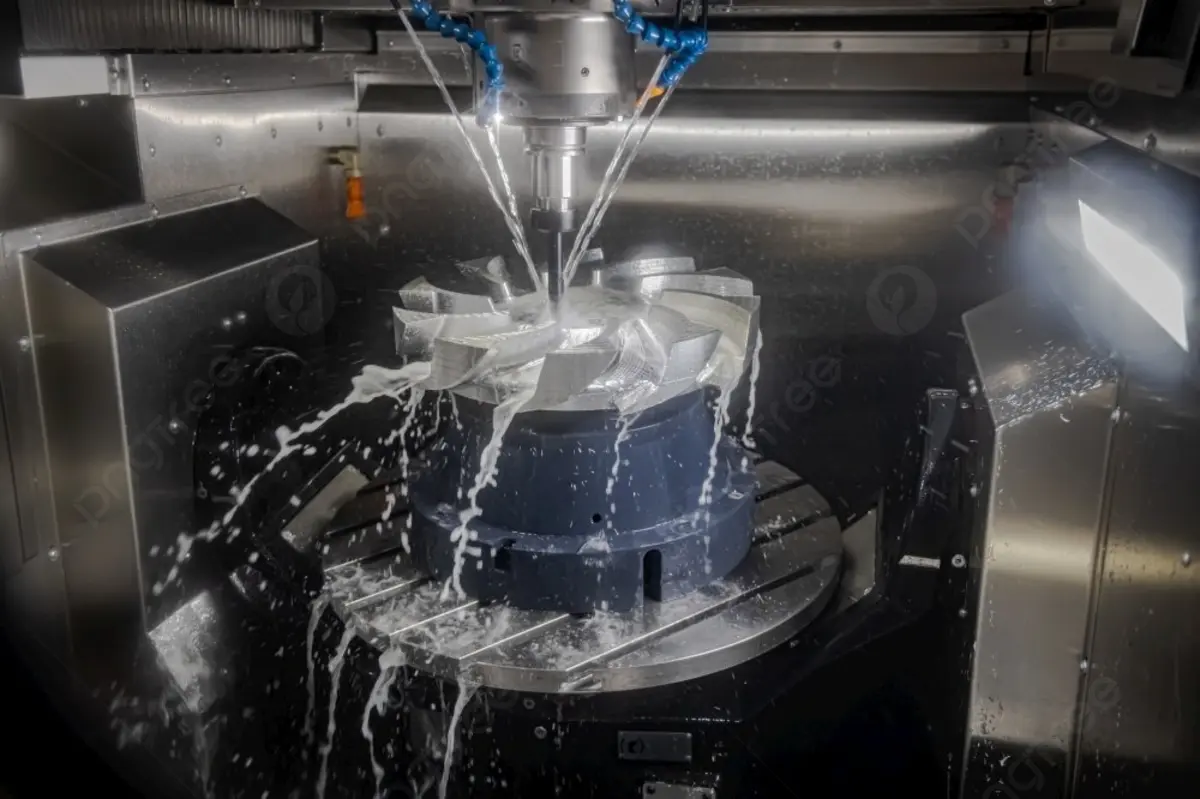

Direct metal laser sintering (DMLS/SLM):

- Print stainless steel, brass or bronze stamps with GreatLight’s SLM 3D printers.

- Provides a durable, heat-resistant seal suitable for sealing large quantities.

- Allows handles or ergonomic handles to be embedded in a single print.

- Investment casting model:

- Print flammable resin master molds via SLA for traditional metal casting.

- The resin evaporates in the kiln, causing deforestation, forming molten metal – perfect for brass or silver seals.

Step-by-Step Guide: Creating a 3D Printed Wax Seal

1. Design stage:

- Create a mirrored 3D model of the seal (vector works best).

- Add a handle/shank extending 25-30mm from the sealing surface.

- Optimize depth (0.5-1.5mm) to get a clear wax print.

2. Printing and post-processing:

- Metal seal (SLM):

- Layer thickness: 20-40μm; Material: stainless steel 316L.

- Post-processing: sandblasting, polishing, anti-stick coating.

- Resin Master (SLA):

- Layer thickness: 25-100μm; Material: castable resin.

- Post-processing: isopropyl alcohol cleaning, UV curing, and ceramic shell casting are optional.

3. Sealing:

- Press clean, heated stamp into