Unleash your creativity: A complete guide to 3D printing your own bucket

Forget the hardware store aisles! Have you ever wanted to have a bucket perfectly customized to your unique needs? Whether it’s for gardening, organizing shop tools, a quirky decorative piece, or a specialized container for your hobby, 3D printing lets you design and create a functional bucket at your desk. This guide will take you from digital concept to tangible reality. Buckle up (or should we say, buckle up?) and let’s get started.

Why print your own bucket?

Standard buckets are everywhere, but they often have shortcomings. Maybe you need an unusual shape to fit in a tight spot, an integrated handle for specific gripping, compartments for organization, or a special aesthetic that complements your space. 3D printing unlocks these possibilities. It allows:

- custom made: Size, shape, wall thickness, handles, drainage holes – design it exactly the way you want it.

- Comprehensive features: Add built-in nozzles, measurement marks, mounting brackets or legs.

- Material selection: Choose filaments with specific properties (water resistance, flexibility, rigidity, or unique colors).

- Rapid prototyping: Quickly iterate on application-specific designs before investing in expensive tooling.

Get ready: what you need

- 3D printer: Any fused deposition modeling (FDM) printer capable of handling the required barrel size can be used. Make sure your print bed is big enough! For smaller buckets or complex parts that require high detail and strength (such as industrial prototypes), considering resin (SLA/DLP) or industrial metal printing may be an option – although desktop FDM is the focus here.

- filament: The choice is crucial, especially if the bucket can hold water:

- People’s Liberation Army: Easy to print, biodegradable and perfect for prototyping and decorating buckets. warn: PLA deforms under sustained high temperatures and It will slowly degrade if kept in water for a long time.

- Polyethylene glycol: Excellent choice! Highly durable, impact-resistant, waterproof, food-safe (with FDA-approved filament), and prints well. Best overall filament for functional buckets.

- ABS: Sturdy and heat-resistant, but emits fumes during printing and requires good ventilation. Printing without distortion can be difficult. More suitable than PLA for non-aqueous applications if higher temperatures are expected.

- Thermoplastic polyurethane: For flexible buckets! Create rubber-like behavior for unique applications such as folding buckets or anti-vibration containers. Printing requires specific settings.

- CAD software: Design your bucket!

- Beginner friendly: Tinkercad (browser-based), SketchUp Free.

- Intermediate/Advanced: Fusion 360 (free for hobbyists/startups), FreeCAD, OpenSCAD.

- Slicing software: Convert your designs into printer instructions (e.g., Cura, PrusaSlicer, Simplify3D).

- Basic tools: Squeegee/spatula (to remove print), side cutter (to clean filaments/debris), sandpaper/file (for post-processing), possibly safe adhesive for bonding multi-part prints.

Design your bucket: CAD Intelligence

- Define requirements: Purpose? size? Opening diameter, depth, wall thickness (recommendation: rigid 2-5mm)? Handle type? Drainage hole? Weight Limit?

- Draw the outline: Start with a 2D sketch outlining the side of the bucket. This usually involves defining a curve (cylinder) or slope (cone).

- Rotate or stake out: The simplest approach to a typical bucket shape is "around" Order. Draw the outline of one side (half of the bucket) and rotate it 360 degrees around the central axis.

- Add base: Draw a circle on the bottom plane and extrude it slightly upward to create base thickness.

- Integration handle: Design a sturdy handle of sufficient thickness (5-8 mm) directly into the barrel wall. Reinforce connection points to avoid breakage. Alternatives include lofting the handle shape from the outer lip downwards.

- Details matter: Add chamfers to top/bottom edges for comfort and strength. Consider adding ribs around the exterior to add structural rigidity without significantly increasing material use.

- Size awareness: Make sure your design fits within your printer’s build volume! For large buckets (>15L), consider designing the bucket as segments/modules that are bolted or clamped together.

- Confirmed: Use CAD tools to measure wall thickness, volume and ensure manifold geometry (waterproof mesh). Consider stress points near the handle.

Slice and print: turning digital into physical

- Import and target: Load your design (.STL file) into the slicer. Orient so the bucket prints vertically (bottom on bed, top open). Printing on the sides minimizes support but compromises circular accuracy and creates weak layer lines in the horizontal direction.

- Floor height: 0.2mm is a good balance for functional strength and decent print speed.

- Wall thickness and perimeter: Crucial! The goal is At least 3-4 perimeter lines. This defines the literal wall thickness. Combined with your designed wall thickness – slicer settings cover CAD walls are thin. Calculation: wall thickness = perimeter * line width.

- filling: For sturdy barrels that require structural integrity, use a fill density of 15-30%. Rectangular, triangular or spiral patterns provide good strength. High padding is generally not required throughout: by using higher padding near the handle attachment point "gradually fill" or "fill anchor" Smarter.

- Support structure: Overhangs within the bucket lip may require support. Optimize the use of tree supports or concentric supports with a small air gap (~0.2mm) to facilitate removal. If possible, avoid providing support on critical interior surfaces. For multi-part prints that are laid flat on the bed, minimal support is usually required.

- Bed adhesion: Large flat bottoms may become deformed. Use edges (~5-10mm) for excellent adhesion; raft provides the highest adhesion, but wastes more material and leaves a rougher bottom surface.

- Printing temperature and speed: Use the filament manufacturer’s recommendations as a starting point. PETG typically prints at higher temperatures than PLA (235-245°C), but at a slightly slower speed. Make sure to cool thoroughly except for the first few layers.

- Print! : Monitor the first layer closely for adhesion and then relax. Large barrels can be filled many Hours or even days.

Post-processing: strength and finish

- Remove carefully: Allow the print to cool completely before removing it from the bed. Use the spatula/scraper gently to avoid damaging the base. Carefully remove the edges and supports.

- Waterproof (critical for PLA/PETG used with water):

- coating: Apply FDA-approved food-safe epoxy sealant (multi-layer) to PLA or PETG barrels intended for long-term water or food contact. UV-resistant polyurethane spray paint can also seal prints.

- Thread sealant: Apply Teflon tape or pipe thread sealant to any threaded joints or plugs.

- limitation: No filament is inherently 100% waterproof and can be submerged in water indefinitely. The seal significantly improves water resistance.

- assembly: If printing in a part, glue carefully using an adhesive suitable for your filament (Super Glue/CA Glue for PLA/PETG, Epoxy).

- Finishing touches: Sand the exterior surface to make it smooth, fill in smaller layer gaps with filler putty if needed, and paint to look nice.

Conclusion: The power of personalized manufacturing

3D printing your own bucket embodies the shift towards personalized manufacturing. It’s no longer just about buying a universal solution; It’s about making tools that are uniquely suited to your life. The process involves creative design, technical understanding of materials and printing, and careful post-processing—especially for functional applications that require strength and water resistance. While desktop FDM printing can help individuals, industrial-grade solutions can unlock greater possibilities.

Beyond the desktop

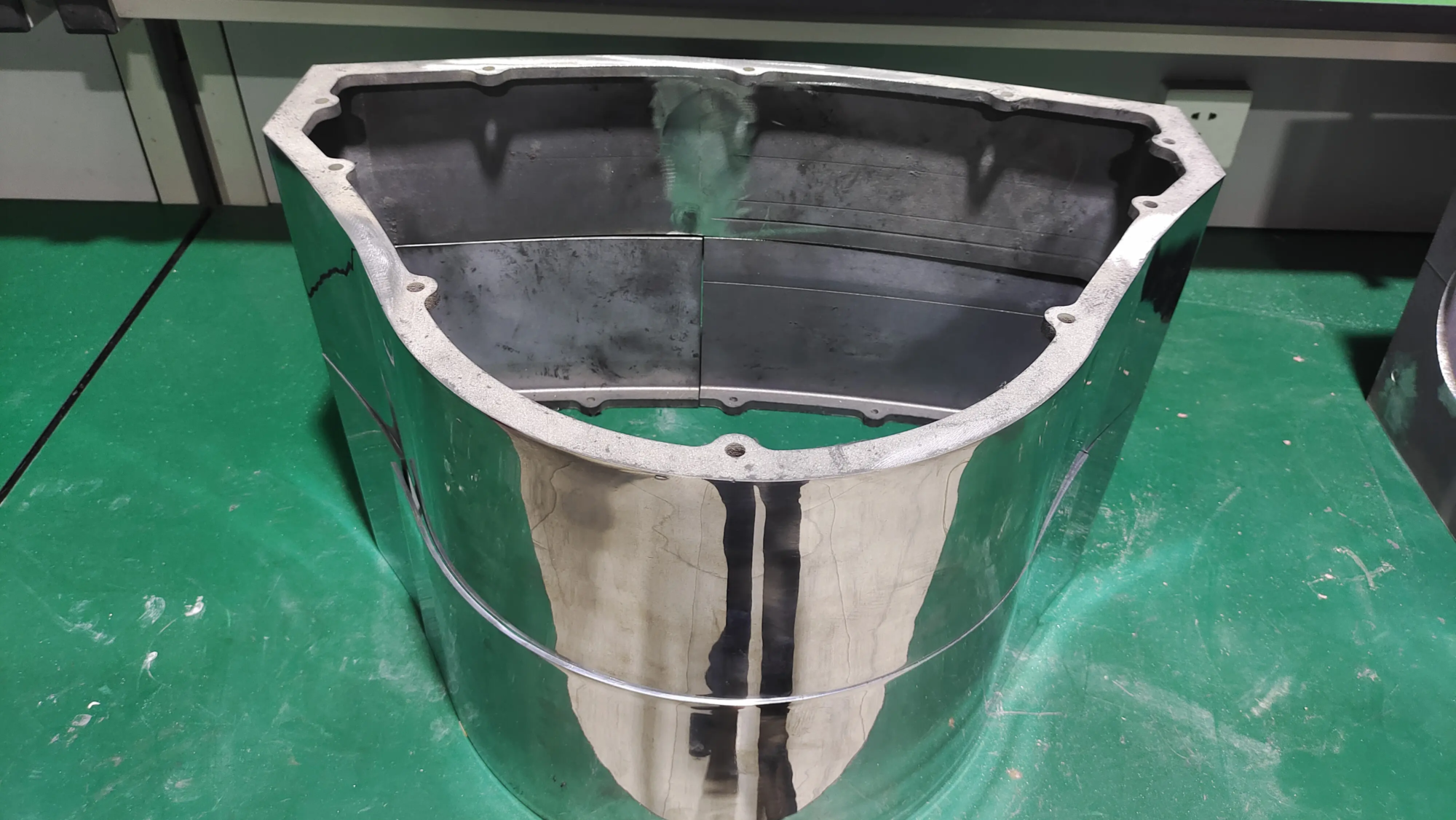

For applications that really require extreme durability, complex geometries, heat resistance, or specific material properties such as titanium or stainless steel, professional-grade additive manufacturing comes into play. huge light Excellent in this field. As a leading rapid prototyping manufacturer, huge light Utilizing advanced Selective Laser Melting (SLM) 3D printers and advanced production technology. They specialize in solving complex metal rapid prototyping challenges – ideal for developing rugged prototypes, tooling, molds or high-performance end-use buckets designed for industrial or professional commercial applications.

huge light More than just printing; they offer comprehensive One-stop post-processing and finishing services – From precision machining and heat treatment to complex polishing and surface coatings. This ensures that metal parts meet strict functional and aesthetic standards. To cater to the needs of different industries, they offer a wide range of Material customizability and give priority to Quick turnaround era, making them one of China’s premier partners Precision rapid prototyping and custom metal fabrication.

Whether you’re finding success with PETG barrels with your home printer, or innovating with durable metal prototypes from experts like huge lightthe ability to 3D print containers confers originality. So fire up your CAD software, unleash your design ideas, and start printing solutions that fit your world perfectly.

Frequently asked questions about 3D printing barrels

-

Can I eat/drink from a 3D printed bucket?

- Not using raw silk! Polylactic acid/polyester fiber Filament type It may be certified food safe, but the printing process can create gaps where bacteria can grow. For direct contact with food, food safe filament add A certified food grade sealant coating must be used. If selling, see regulations.

-

How strong are 3D printed buckets?

- Strength is highly dependent on filament selection (PETG > PLA > PLA+), wall thickness, number of perimeters, fill percentage/pattern and layer adhesion. Well-designed PETG buckets have thick walls (~4mm+) and sufficient girth to be very sturdy for typical lifting/dumping tasks. Avoid excessive impact.

-

What is the largest bucket I can print?

- Limited by printer print volume. The maximum print barrel diameter of a common desktop printer (220x220mm) is about 10L (about 200mm). Larger printers exist, or your design can be sectioned and assembled.

-

Why is my print bucket leaking?

- Tiny gaps between layers or within the perimeter can cause leaks. Ensure adequate wall thickness/girth, good extrusion calibration, proper hot end temperature, and consider annealing (PETG) or coating/sealing, especially for liquids under pressure.

-

Is it possible to 3D print metal buckets?

- Absolutely, although usually on an industrial/commercial scale. Companies like GreatLight use SLM/DMLS/Metal FDM technology to print rugged stainless steel, aluminum or titanium barrels and containers, ideal for harsh environment, aerospace, automotive or specialized industrial uses where ultra-high durability and accuracy are critical.

-

It’s PETG really Waterproof?

- PETG is hydrophobic in nature and more water-resistant than PLA. For brief contact/splash it generally performs well unsealed. For long-term liquid holding, submersible or pressurized applications, sealing is highly recommended for long-term leak-proof performance and hygiene.

- How to design a handle that won’t break?

- Significantly thicken the handle profile where it connects to the bucket body – use fillets or chamfers to spread stress to sharp corners. Print handles with thicker walls/padding, or orient them for increased strength against bending forces. Use PETG or TPU instead of PLA for better impact resistance.

Go print now! Let us know about your unique barrel creations in the comments below.