How to “lift” the liquid metal that originally flowed like “whipped cream” and apply it to 3D printing?

Recently, the research team of Professor Bai Hua and Associate Professor Hu Xiaolan from the School of Materials Science and Technology, Xiamen University, has made significant progress. They prepared a new type of high internal phase liquid metal emulsion gel that can be directly used for 3D printing. At the same time, for the first time, it was possible to activate the conductivity of ink by applying an electric field, and ultimately realize liquid metal 3D printing in a variety of complex scenes. The relevant results have been published online in “Nature Communications”.

Behind the story of “making the liquid metal hold” is the team’s hard work for three consecutive years.

When liquid metal meets 3D printing

Liquid metal is liquid at room temperature, can change shape at will, and has good conductivity. It is an important material in the fields of wearable and implantable biological devices and soft robots.

3D printing is an important material processing technology, and the combination of liquid metal and it can bring new possibilities to material processing. However, 3D printing to make objects is a bottom-up process, which requires the materials used to be in a certain solid state, which is obviously not possible with flowing liquid metal.

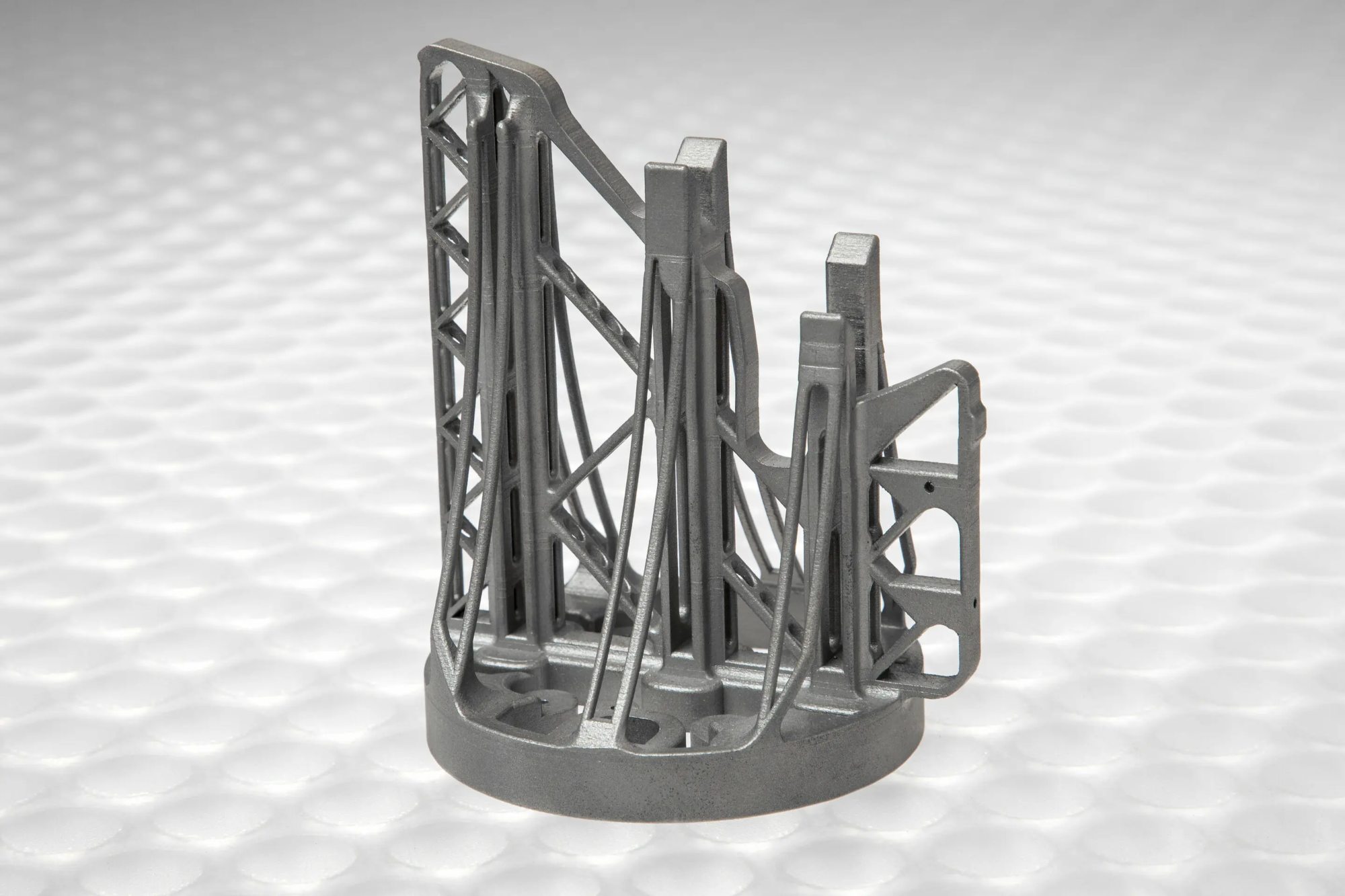

Therefore, how to combine the two to achieve the “1+1>2” effect is a difficult problem that Professor Bai Hua’s team wants to solve. Bai Hua said: “We looked for a way to keep the liquid metal in the desired shape, so that it could be ‘erected’ in a three-dimensional space like a large building.

Lin Zewen, a doctoral student in Professor Bai Hua’s team, thought that by beating the sticky egg white, it would stop flowing after foaming and become a relatively stable cream. If some kind of material is added to the liquid metal, it will become something. between liquids. The emulsion between the solid and the solid forms a build-up between the particles, which allows it to retain its shape and its “branche” like butter. Finding suitable materials is what he has been thinking about and researching since 2021.

When “luck” knocks at the door

What exactly are these building materials?

During the 2021 winter vacation, Lin Zewen was still seriously thinking about this question. This material allows the liquid metal to “foam”, but it cannot affect the conductivity of the liquid metal itself after printing, as if it disappears. When Lin Zewen was using hand cleaning gel, he found that the hand cleaning gel disappeared during use, so he decided to try combining it with liquid metal to see what would happen.

Fortunately, he discovered that Carbopol molecules, the key ingredient in hand sanitizer, and liquid metal are a “perfect match.” They can interact with the surface of the liquid metal and, after stirring at high speed with a device similar to a milk tea stirrer, the tiny droplets of liquid metal accumulate together, creating an emulsion-like liquid metal ink that can be extracted from the nozzle of a printer and retain its three-dimensional shape, just like butter extracted from a piping nozzle.

Preparation process and formation principle of liquid metallic ink

Just like whipped cream requires certain ingredients, preparing liquid metallic ink is by no means as simple as mixing direct hand wash gel with liquid metal. Lin Zewen must prepare his ideal “hand washing gel”. What is the gel to liquid metal ratio, how long it should be stirred, what air pressure is used during the printing process, and what size needle is used. data must be collected only once. A single experience can determine. He said: “When you have an idea, you have to implement it. If you do it, you may fail, but if you don’t do it, you certainly won’t succeed.

In subsequent experiments, just as luck knocked on the door, Lin Zewen was even more surprised to find that although the “hand cleaning gel” is an insulating gel, the liquid metal ink can still maintain conductivity high when electricity is applied. This accidental discovery of innovative points surprised Lin Zewen: “I didn’t even want to eat, I just wanted to go to the laboratory to do experiments.”

Lin Zewen also took advantage of this chance with his own experiments and research. Under the guidance of Professor Bai Hua and Associate Professor Hu Xiaolan, he published relevant research results on liquid metal 3D printing online in “Nature Communications” as the first author. superior.

Scientific research “colleagues” with different divisions of labor

“Good projects are carried out, and the best source of inspiration for students’ scientific research is themselves.” The team atmosphere between Professor Bai Hua and Associate Professor Hu Xiaolan is relaxed. As long as it is a subject that has academic and practical value, Bai Hua will encourage students to do it courageously and try. He believes that scientific research is not about students “working” for teachers. In fact, tutors and students are scientific research “colleagues” with different divisions of work, and both are. essential.

Bai Hua will give its students enough space to explore interesting topics that interest them, allowing them to conduct experiments and research independently, cultivate the ability to solve problems independently, and engage in research careers. He hopes that “students will truly learn from scientific research.” ” method and feel the pleasure. ” And he gives timely advice: “A mentor is a person who helps students when they encounter difficulties in independent exploration. »

Bai Hua guides students in analyzing electrochemical data

The materials and mixing methods Lin Zewen chose for liquid metal 3D printing were mainly explored through his own experiments. When he was trapped by theoretical knowledge and could not explain the principles, Bai Hua communicated with him several times and sent him a book on the subject. for mortar pumping – “Rheology of metal ore pastes”. “I was very confused at first, what is the relationship between mortar pumps and liquid metal?” After reading, he found that the properties of mortar pumps can be compared with those of liquid metal, and he had to sigh that Master Bai had already led the way and I was just waiting. I let myself discover the answer. “Lin Zewen said.

The team of Professor Bai Hua and Associate Professor Hu Xiaolan mainly studies polymer materials. They mainly use organic materials to study some questions in the fields of energy and sensing, and use organic materials to convert, store and sense energy.

In addition to liquid metal 3D printing, their research direction also includes structural energy storage devices, which means developing powerful batteries so that in addition to storing energy to power electric vehicles, they can also develop structures themselves, that is to say manufacture them. what the shell or chassis of the car looks like. It can also be simply said as “using the chassis or shell of the car to store energy.”

In the future, the team of Professor Bai Hua and Associate Professor Hu Xiaolan will continue research on the direction of liquid metal 3D printing. They will continue to explore the depth of this direction, continue research, explore repeatability and stability. of products, and try to combine it with other industrial materials to promote its application in actual industrialization.