On June 13, 2024, according to the Resource database, on May 30, the Indian space startup Agnikul successfully launched a rocket equipped with a 3D monopoly rocket engine. After the launch, the rocket reached an altitude of 6.5 kilometers, then fell into the ocean, successfully completing the technical verification mission. This successful launch marks an important step towards the launch of “on demand” rocket.

Agnikul said that launch is not only a technical demonstration, but also a complete test of all key subsystems, including flight computers, planeic, advice and navigation systems and launch ramps built specifically for the mission. While reaching the goal of Newton 6K Thrust, the team also managed to lead wind maneuvers, that is to say by adjusting the trajectory of the rockets during the flight to adapt to the influence of the wind. Thanks to this launch, the company has acquired precious experience in manufacturing and launching operations.

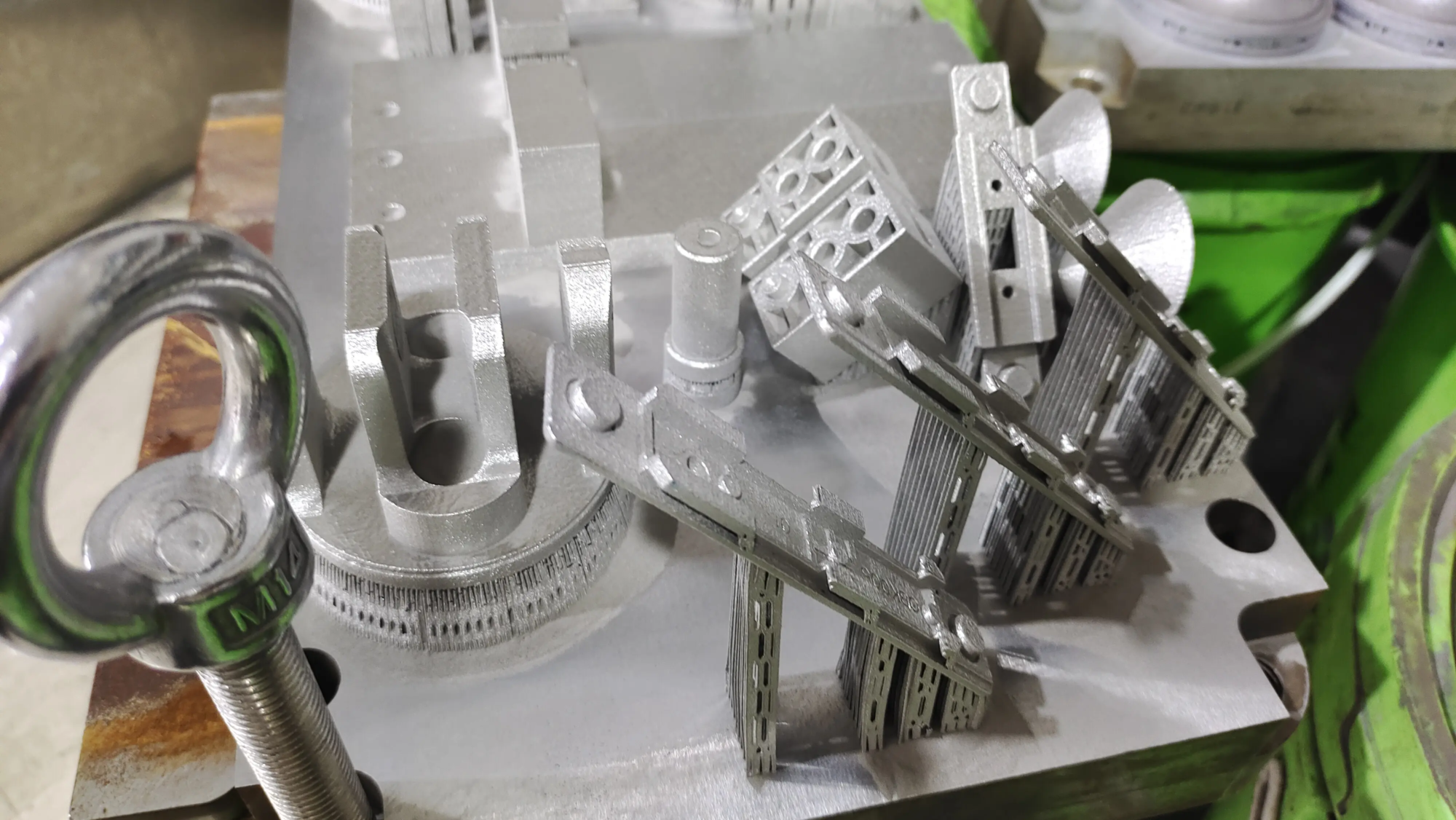

In just 72 hours, 3D printing of the rocket engine

The launch has also proven the rationality of the unconventional manufacturing method of Agnikul. The traditional method takes 10 to 12 weeks to build a similar -size rocket engine and carry out in -depth identification and tests. Thanks to the Metal 3D Metal Printer of the German company EOS, Agnikul finished engine production in about three days. Printed engines with a nickel chrome alloy can withstand high temperatures and mechanical loads. The printer automatically generates reports that record printing differences in detail, eliminating the need for post-fabrication identification.

It takes about two weeks to assemble the rest of the rocket and integrate the engine. Agnikul said that this provides low -cost launch services, “on demand” for small satellite operators, otherwise they will have to wait a greater rocket.

It is understood that Agnikul was founded at the end of 2017 and initially attempted to use 3D printed components such as lining, cooling channels and fuel injection points. However, he gradually crossed the limits and began to combine different components together, avoiding welding and tightening, and freeing himself from the constraints of traditional methods. On April 2, the company said it has successfully tested its 3D printed cryogenic engine called Dhawan-II for 200 seconds.

Sorted Agnibaan: commercial products soon arrive

Agnikul’s first trade product is a two -step rocket called Agnibaan, 18 meters high and equipped with eight engines which can deliver 300 kilograms of payload at an altitude of approximately 700 kilometers. The rocket tested in May is only 6 meters high and was equipped with a single engine, equivalent to the second stage of the Agnibaan.

The co-founder and CEO Srinath Ravichandran revealed that the biggest challenge at the moment was to change the only monomotor engine of Agnibaan to a cluster with seven engines. This presents many challenges, from the balance of the thrust of the engine to takeoff in the management of the interaction of the plume when the universal joints of the engine change the trajectory. “But these problems have already been solved,” he said. “We believe he is able to compete according to the requirements of the task, then to move on.”

Ravicandran said that the company is currently building an installation for engine units on the ground and plans to carry out its first orbital launch this time next year.

In fact, it is not only Agnikul who develops rockets thanks to 3D printing. On March 22, 2023, the first rocket printed in 3D in the world “Human One” of the relativity space was successfully launched, but failed to enter smoothly. The main private rocket companies in China, including Deep Blue Aerospace, Blue Arrow Aerospace and Tianbing Technology, also manufacture rockets thanks to 3D printing.