Unlocking acoustic innovation: The rise of 3D printing horns

For centuries, the corners from musical instruments to industrial sirens and automotive components – have been affected by traditional manufacturing restrictions. Forming, forging and machining determines the complex internal geometry, material selection, and ultimately the performance and cost boundaries. But a quiet revolution is unfolding. 3D printing, especially advanced metal additive manufacturing (AM), such as selective laser melting (SLM), fundamentally changes our design and production angles, opening doors for unprecedented acoustic capabilities and design freedom.

Go beyond the limitations of traditional handmade

Traditional horn manufacturing faces inherent challenges:

- Complex geometric shapes: It is well known that internal pathways that are crucial to sound wave formation and amplification are difficult and sometimes impossible, and can be precise and cost-effective.

- Material Limitation: The required high-performance alloys have strength or specific acoustic properties, and it is difficult to use the subtraction method.

- Weight and strength: A horn that optimizes sound efficiency often requires lightweight but solid structures that are structurally inefficient for conventional efficiency.

- Prototype bottleneck: Iterating on acoustic design through traditional prototyping is slow and expensive, suffocating innovation.

This is where metal 3D printing is, especially SLM technologyas a game changer.

SLM Advantages: Accurate, Free, Performance

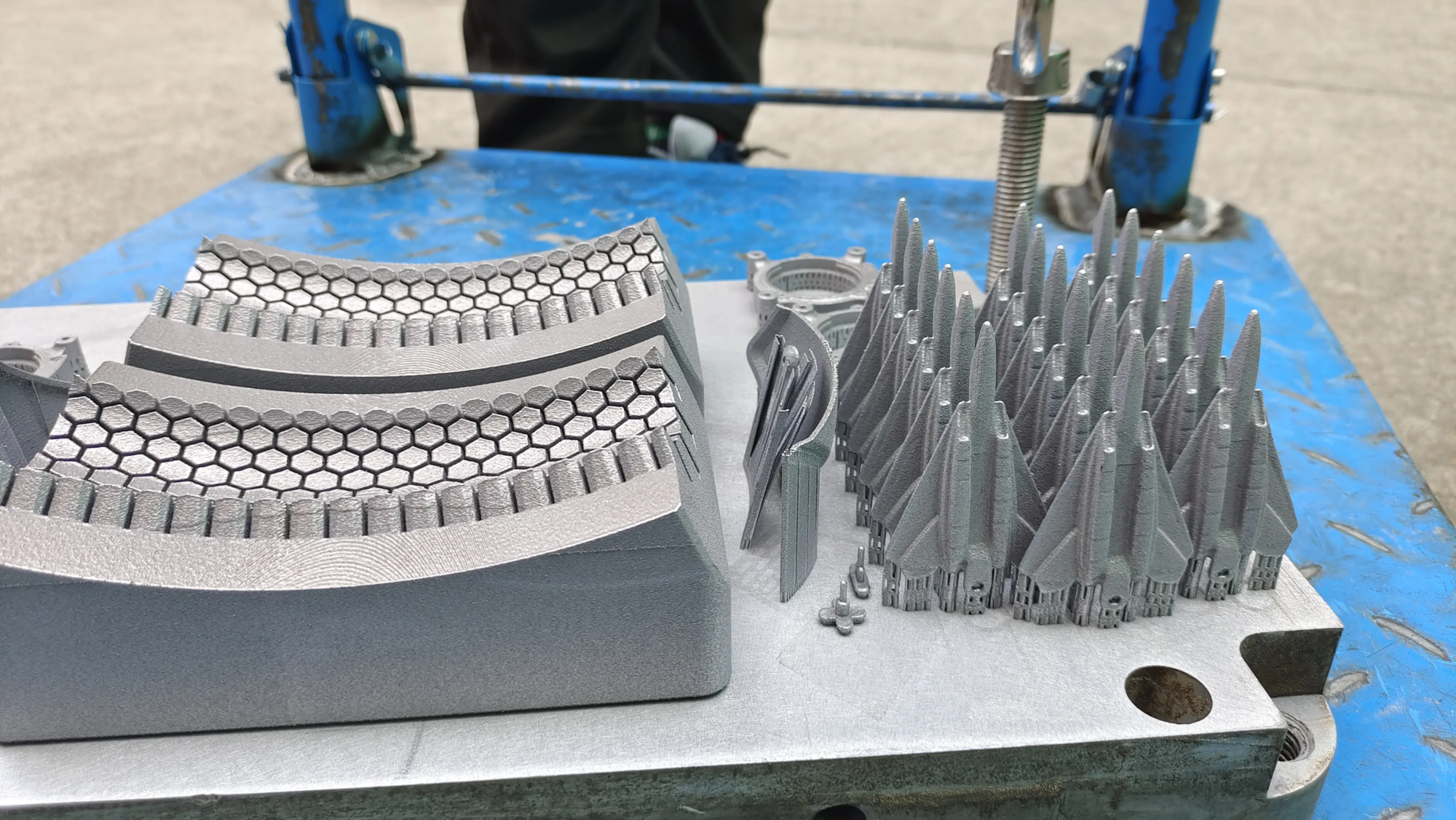

Selective laser melting Use high-power lasers to carefully fuse fine metal powder particles layer by layer to construct complex parts directly from 3D CAD data. For horn design, this unlocks the area of possibility:

- Geometric freedom without boundaries: SLM specializes in creating complex internal channels, cavity, curves and complex surface textures, just like acoustic engineers design. This allows:

- Optimized waveguide: The diagonal flare rate and precise control of internal shape directly affect sound quality, directionality (directionality) and efficiency. SLM can create mathematically ideal, smooth and consistent waveguide geometry in other ways.

- Integrated features: Installation brackets, cooling fins, structural reinforcements, and even embedded sensors can be designed Within The horn structure itself is printed in a single way, reducing components, weight and potential points of failure.

- Lightweight by design: Am OK Lattice structure and Topology optimization. Only the structure needs to be placed, resulting in maintenance or even Increase Rigidity and strength. This is crucial for applications in aeronautical or automotive audio systems.

- Material versatility and performance: SLM can handle a wide range of high-performance metals that are critical to demanding horn applications:

- Stainless steel: Provides excellent corrosion resistance and durability.

- Aluminum alloy: Lightweight, suitable for high-frequency response and lightweight applications.

- Titanium alloy: Excellent strength ratio and corrosion resistance for aerospace and advanced audio.

- Copper or nickel alloy: Explore specific acoustic characteristics or thermal management needs.

- Tool Steel: Molds used in subsequent conventional polymer angle manufacturing.

- Quick Prototyping and Customization: The digital nature of AM means that design iterations are very fast. Want to adjust the flare profile a little? Just adjust the CAD file and print a new prototype overnight. This accelerates the development cycle and makes custom or custom angles economically viable.

Greglime: Your partner in cutting-edge acoustic manufacturing

At Greatlight, we are at the forefront of industrial SLM 3D printing. We learned that converting innovative acoustic designs into high-performance, reliable metal components requires more than just printers. It requires:

- Advanced SLM Infrastructure: We invest in state-of-the-art SLM equipment to ensure accuracy and repeatability at scale.

- Production-level expertise: We go beyond the prototype. We have the ability to process series production of 3D printed angles using SLM, thereby maintaining strict quality control.

- Deep Material Knowledge: Our team has the expertise to select and handle the best metal powders for Horn’s specific acoustic properties, environmental conditions and structural requirements.

- End-to-end post-processing: Printing the horn is just the beginning. GREMPHILE provides a comprehensive One-stop post-processing and completion service – Includes meticulous support removal, pressure relief, precise adjustments to heat treatments for materials and applications, precise machining of critical interfaces (if required) and a range of finishes (polishing, media blasting, plating, powder coatings) to meet the exact specifications and aesthetics.

- Quick turnaround: We leverage our technical and process expertise to deliver obvious Quick turnaround timeeven for complex metal parts.

Application: 3D printing horn resonance

In various industries, people have felt the impact of 3D printing angles:

- Hi-Fi audio: Audiophile speaker manufacturers are creating angles with waveguides designed for excellent sound purity, dispersion and detailed sound reproduction. Customization can be perfectly integrated into unique speaker designs.

- Professional audio and PA systems: Speakers in concert halls, stadiums and tour systems, durable, lightweight and acoustically optimized speakers provide improved sound projection and weight-reducing rigging.

- car: Integrating compact and powerful angles within constrained vehicle spaces (for example, for alarms, tweeters) often benefits from lightweight. Custom designed for signature sound or brand identity.

- Industry and Safety: Reliability is crucial for the powerful, corrosion-resistant siren and warning angles of harsh environments (marine, chemical plants, oceans). Complex internal geometry can achieve specific acoustic features at different warning levels.

- Aerospace and Defense: Lightweight, structurally integrated horns for communication systems that remind the equipment and sensors in aircraft and spacecraft, counting and performance per gram are essential under extreme conditions.

- R&D: Rapid prototyping and testing new angular acoustic designs were previously considered impossible to manufacture.

Conclusion: The future of sound and hearing

The angles of 3D printing are not only representing manufacturing offsets. They represent fundamental developments in acoustic design. By leveraging the power of SLM technology, we can eventually escape the geometric and material limitations of the speaker performance for a long time. The ability to create lightweight, structurally efficient, highly optimized, and highly complex or custom angles in robust metals opens up huge potential for innovation in countless areas.

As a pioneer in this space, Greglight is committed to working with designers, engineers and manufacturers to break through possible boundaries in acoustic components. Whether you need a single high-precision prototype or a production run of complex metal angles, our advanced SLM capabilities and comprehensive finishing services offer reliable, high-quality and innovative manufacturing pathways. The future of sound is layer by layer.

FAQs About 3D printed horns

-

Is the angle of 3D printed as good as the angle of processing?

- In many cases, they are Better. SLM 3D printing allows internal geometry to optimize acoustic performance (such as smooth waveguides, complex curves) and cannot be processed internally. They can also be lighter and can also be more powerful, or even stronger in an optimized design. The finishes are different, but can be improved through our post-processing services.

-

What are the main material choices for 3D metal angles?

- Common options include a variety of stainless steels (316L, 17-4PH), durability and corrosion resistance, aluminum alloys (ALSI10MG, ALSI7MG, good acoustic properties for lightweight) and titanium alloys (TI6AL4V) (TI6AL4V) to obtain the best advantage in critical applications. Copper or special alloys can also be explored for unique acoustic properties.

-

Can 3D printing handle the tight tolerances required for angles?

- Yes, like the modern industrial SLM printers used by Greatlight, very tight tolerances (usually at ±0.1 mm or higher). During post-processing, critical interfaces requiring tighter tolerances can be achieved through combined AM and precise CNC machining.

-

The durability of 3D printed metal angles?

- SLM produces nearly dense metal parts. When suitable for AM design and performing proper post-processing (stress relief, heat treatment), 3D printed metal horns exhibit excellent mechanical properties, comparable to cast or forged equivalents, and sometimes even superior. They are highly durable for applications requiring them.

-

Is 3D printing of diagonals cost-effective?

- it depends. For simple geometry, conventional methods may initially be cheaper. But 3D printing shines for complex, lightweight integrated designs: it eliminates expensive tools, reduces material waste, cuts assembly steps, and can be iterated quickly. For prototypes, custom-designed or performance-optimized series parts, it is often the most cost-effective and innovative solution. Greatlight offers competitive pricing tailored to project requirements.

-

Which file format do I need to start a project?

- We need a high-quality 3D CAD model, usually in step (.STP) or IGES (.IGS) format. Our engineering team can work with you to ensure that the model is optimized for additive manufacturing.

- Can Greatlight provide design support for my Horn project?

- Absolutely! When you provide acoustic requirements or initial concepts, our experienced engineers specialize in Additive Manufacturing (DFAM) design. We can optimize your horn design to leverage the full capabilities of SLM technology for printability, performance, weight and cost-effectiveness. Contact Greatlight today to discuss your next breakthrough acoustic component!