Unleashing Innovation: The General Guide to Lion 3D Printing – Your Blueprint for Success in Rapid Prototyping

The world of manufacturing is undergoing a fundamental transformation, while 3D printing is firmly at the forefront. Whether you are an engineer designing the next breakthrough product, the entrepreneur’s prototype is a game-changing invention, or a designer, pushing the boundaries of form and function, mastering this technology is crucial. enter Lion 3D Printing Master Guide – Not only a manual, but a comprehensive concept and method to achieve an unparalleled additive manufacturing industry, especially for demanding metal applications. This guide distiles years of industry experience and cutting-edge practice into actionable insights.

Why Mastering Metal 3D Printing Is More Important More Than Ever

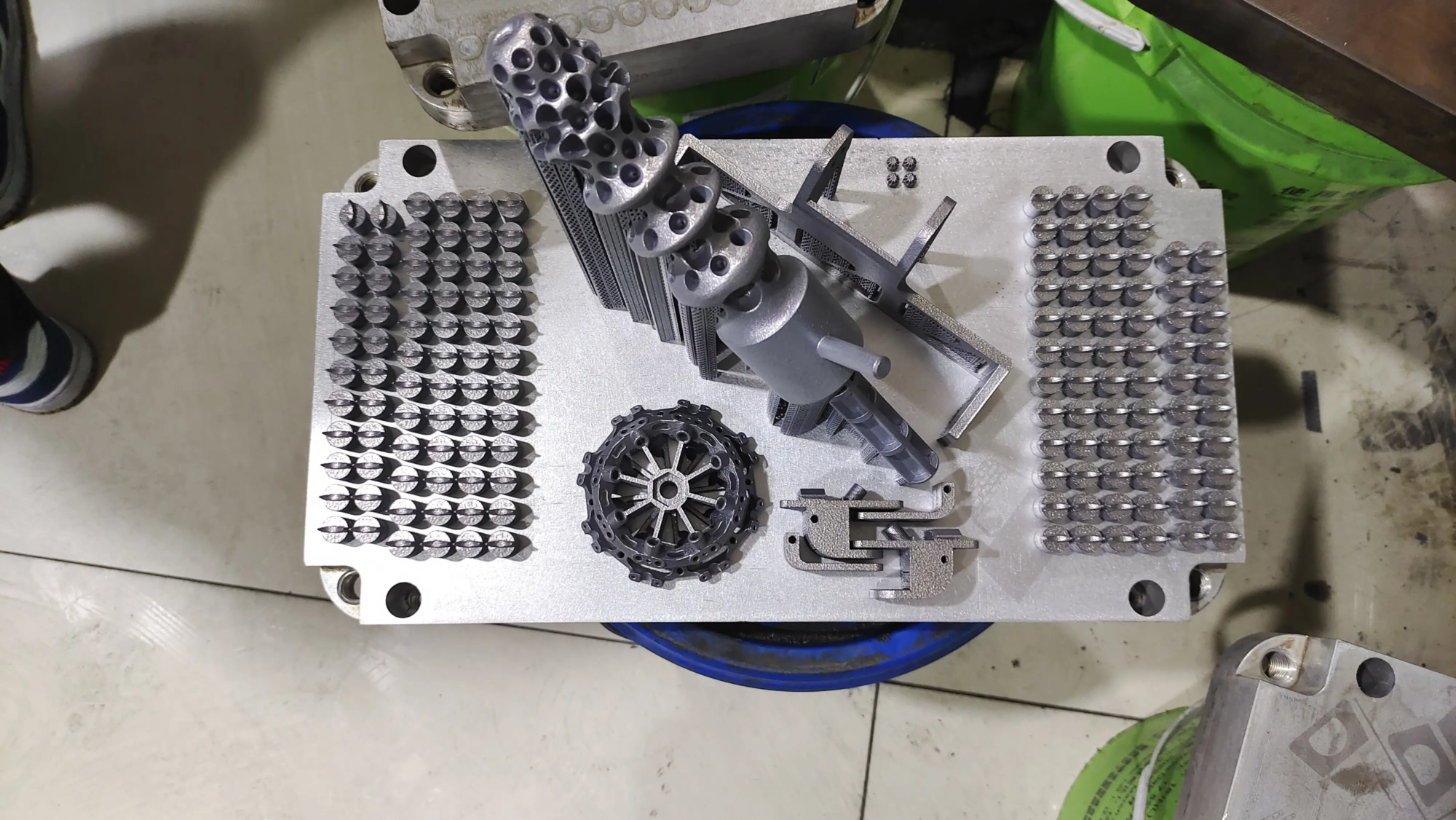

Gone are the days when 3D printing is used only for plastic trinkets. Selective laser melting (SLM)This is a leading metal additive manufacturing technology that creates complex, high-strength functional metal components directly from digital models. This unlocks:

- Unprecedented design freedom: Create geometric shapes through traditional machining – internal channels, lattice structures, organic shapes.

- Quick time to market: Iterative designs in days rather than weeks or months.

- Lightweight and optimized: Build parts with an optimized topology for maximum strength and minimum weight.

- Parts merge: Combining multiple components into a single printed part reduces assembly time and potential failure points.

- Production on demand: Cost-effectively produce small volume or highly customized parts.

General Guide to Lion 3D Printing: Professional Columns

The General Guide to Lion 3D Printing is built on deep technical and practical knowledge, which reflects the pinnacle of the best practices of rapid prototyping. It emphasizes a holistic approach covering each key stage:

- Design of Additive Manufacturing (DFAM): This is basic. This guide dives deeper into the standard CAD principles and teaches how to take advantage of SLM. This includes understanding support for structural optimization (critical for minimizing distortion and post-processing), minimizing thermal stress through intelligent orientation, utilizing energy to reach intensity-to-weight ratios, and ensuring productivity from the first sketch. This is about design for This process, not only although it.

- Material mastery: Not all metals have the same effect under the intense heat of the laser. The Lion Guide provides a detailed knowledge of a wide range of materials:

- Titanium alloy (TI6AL4V): The gold standard for strength to weight ratio, biocompatibility (implant) and aerospace applications. It is crucial to understand its sensitivity to oxygen and thermal cycles.

- Stainless Steel (316 liters, 17-4ph): Suitable for powerful industrial parts, medical tools and applications that require corrosion resistance. Managing residual stress and optimizing hardness are key.

- Aluminum alloy (ALSI10MG, ScalMalloy): Ideal for lightweight structural components that require good thermal properties. Controlling porosity and surface finish is crucial.

- Nickel Superalloy (Inconel 625, 718): Conquering extreme environments found in aerospace, gas turbines, and oil and gas requires complex knowledge of high temperature behavior and heat treatment.

- Tool Steel (H13, Maraging Steel): For durable molds, molds and tool plug-ins, focus on hardness, wear resistance and managing distortion during printing and heat treatment.

- Exotics & Custom Alloys: Push the boundaries with cobalt powder, copper alloys and custom material formulations tailored to specific performance requirements.

- SLM Process Optimization – The Core of Quality: Just hit "Print" Not enough. This guide elaborates on the complex interactions of parameters:

- Laser and Scan Strategy: Optimizing the energy density (J/mm³) is crucial – resulting in a lack of fusion defects too low; too high can lead to keyholes (vapor cavity) and excessive thermal stress.

- Layer thickness and beam focus: Balance resolution, surface quality and build speed. The finer layer improves details but increases build time.

- Inert atmosphere control (usually argon): Oxygen/nitrogen pollution greatly weakens part of it. Maintaining the conditions of super-color rooms is not commercially acceptable.

- Thermal management: Learn about heating/cooling cycles, preheating strategies and adaptive scanning modes to minimize distortion and residual stress rupture.

- Advanced post-processing integration: Metal parts rarely detach from the build boards ready for use. The Masters of the Lion Guide takes post-processing as a strategic phase, not an afterthought:

- Support removal: Technology (wire EDM, machining, manual) balances speed, accuracy and minimizes surface damage.

- Relieve pressure and heat treatment: It is crucial to achieve the final mechanical properties (tensile strength, ductility, fatigue life) and dimensional stability (especially for alloys such as Ti-6-4, Inconel, tool steel, etc.). Heat isostatic pressure (HIP) is crucial for aerospace applications that eliminate internal porosity.

- Surface finish: Comprehensive options include CNC machining for critical tolerances, precise CNC machining, grinding/polishing (RA values) at all levels, tumbling, shooting, fatigue resistance, electropolishing for biocompatibility/cleanness, and specialized coatings.

- Quality Control and Non-Destructive Testing (NDT): Strict protocols involving dimensional inspection (CMM), ultrasound testing (UT), X-ray computed tomography (CT scan), dye penetrants and tensile testing to ensure integrity and traceability.

Why collaborate with Greatlime: Embodying the Spirit of the Lion Guide

The General Guide to Lion 3D Printing is not only theoretical – it’s Greglime, one of the leading rapid prototyping companies in China. Our commitment is to transform your design into flawless functional metal reality guided by this deep expertise:

- The most advanced SLM Arsenal: We invest in the latest generation of SLM printers with high power lasers, advanced scanning systems, and a carefully controlled build environment for ultimate accuracy and repeatability, especially for complex geometries.

- Material Spirit: In addition to providing standard materials, we also specialize in the treatment of challenging alloys and actively cooperate on customized materials development projects. We understand the unique requirements of titanium for medical implants with the inconel of turbine blades.

- real "One-stop" Expertise: Greglight not only prints, we Finish. Our integrated facilities handle the entire journey – from best DFAM consultation, meticulous SLM production to Everything is necessary Post-processing phases (including complex machining, hip joints, professional finishes and non-destructive testing). This ensures seamless quality control, faster turnaround speeds and eliminates logistical headaches.

- Customization and speed: Do non-standard alloys need in extreme conditions? Need a unique finish? Our agility allows us to adapt to processes and provide customized solutions efficiently, often faster than traditional methods.

- Cost-effectiveness of passing capabilities: Applying the principles of the Lion Guide means minimizing waste, reducing the need for trial reprints, optimizing material usage, and ensuring the right parts are correct for the first time. This means you can save a lot of money on your high-quality prototypes and production parts.

Conclusion: The Future of Command Manufacturing

The General Guide to Lion 3D Printing not only represents technical steps; it embodies an accurate, profound understanding of matter and a mindset of overall process mastery, which is crucial to unlocking the full potential of metal SLM. In the competitive landscape, leveraging this level of expertise is not optional – it is the cornerstone of innovative leadership.

Greatlight is committed to implementing these principles on behalf of your partner with extraordinary skills. We combine state-of-the-art equipment, profound materials science knowledge and comprehensive post-processing capabilities to effectively and cost-effectively solve the most demanding rapid prototyping challenges. If you want to go beyond basic 3D printing to achieve True functional, reliable, production-grade metal componentsmaster the process With the right partners It’s the key.

Ready to bring the most ambitious design into the confidence of master expertise? Work with Greatlime – Your journey of excellence in rapid prototyping begins here.

FAQ: General Guide to Lion 3D Printing and Greatlight Services

Q1: What exactly is it "Lion 3D Printing Master Guide"?

A: This is a comprehensive method and knowledge developed from a wide range of industry experience, with the focus on mastering metal 3D printing (especially SLM). It covers everything from AM (DFAM), materials science, process parameter optimization to basic post-processing techniques, providing an overall blueprint for success.

Q2: Is this guide specific to Greatlight?

Answer: And in principle The Lion Guide represents common best practices for advanced metal AM, and Greglight embodies these principles in our operations, services and expertise. We use this deep knowledge to deliver outstanding results to our clients.

Q3: Which metals can be 3D printed using SLM Greatlight?

A: We handle a wide range of titanium alloys (TI6AL4V grade 5 and 23), stainless steel (316L, 17-4PH), aluminum alloys (Alsi10mg, ScalMalloy), nickel superalloy (Inconel 625, 718), tool steel (H13, H13, Maraging Steel 3ni3ni 300 nni 300 nni ofer Maraging 300, CORR MARAGING 300, CORM) copper and a variety of custom alloys. Material selection depends entirely on the requirements of your application.

Question 4: What makes Greatlime "One-stop" Is the service different?

A: Many companies only offer printing. Provided by Greghime End-to-end service: Expert DFAM consultation, advanced machine printing SLM, and Under one roof, all necessary post-machining (support removal, heat treatment, hips, CNC machining – turn, grinding, milling, surface finishing, professional coating). This ensures seamless quality control, faster delivery and superior final part quality.

Q5: How do I make sure my parts are designed well for SLM?

A: This is the crucial point of the DFAM pillar of the Lion Wizard. Consulting with our experts early in the design phase is crucial. We will review your model for printability, recommend optimizations for reduced support and strength, suggest direction recommendations, and suggest tolerances suitable for AM and any planned post-surgical tolerances.

Q6: Can you handle complex, high-precision components?

Answer: Absolute. SLM performs well in complexity. Our advanced machines, strict process control, and integration of precise CNC machining in post-processing enable us to generate impossible or expensive impossibility or expensive tolerances (usually reduced to IT7 or higher) in a conventional way.

Q7: How fast is it "Rapidly" Prototypes with metal SLM?

A: Speed depends on part size, complexity and material. And the SLM building itself may take several hours to several days, "Rapidly" The aspects come from eliminating lengthy mold or complex processing settings. By receiving your model, we usually pass functional metal prototypes internally How many days or weeksmuch faster than traditional manufacturing. Contact us for a project-specific schedule.

Question 8: Why choose Greatlight over other rapid prototype companies?

A: Our combination In-depth technical proficiency (Lion Guide Principles), Comprehensive features (Printing + extensive post-processing), Material expertise,,,,, The most advanced SLM equipmentand Competing Price Position us as leaders, especially for the requirements for metal prototypes and end-use parts. We focus on being a real problem with complex applications.

Q9: How to start a project?

A: Just contact us! Provide your CAD model (steps/IGES/SLDPRT/etc) and provide detailed information on part features, material preferences, quantity, tolerances, finish requirements and schedules. Our expert engineering team will review it, provide DFAM feedback (if needed), and provide competitive quotes and lead times. Customize your precision rapid prototyping project now!