Micro Revolution: The World of Micro Farms and 1/64 Scale 3D Printed Toys

Imagine a world where the intricacies of farm life are captured in stunning detail, yet small enough to fit in the palm of your hand. Welcome to the fascinating realm of Tiny Farm – an emerging niche where enthusiasts showcase incredibly detailed 1/64 scale miniature farms, tractors, animals and landscapes, created primarily using the transformative power of 3D printing. This isn’t just child’s play; it’s a sophisticated hobby that blends art, engineering, and cutting-edge manufacturing, driven by a community passionate about small-scale surrealism.

1/64 scale: precision meets charm

The 1/64 scale (roughly translated as the average height of humans and similarly scaled down machinery is just one inch) has a unique appeal. It offers the best balance between size and intricate detail. It’s large enough to achieve excellent visual fidelity – imagine a barn door with functional hinges (printed in place!) and users can see miniature animals displaying realistic textures – but still compact enough to display delicate dioramas in a modest space. This kind of scale is ingrained in collectible culture (think classic die-cast vehicles), but significant advances have been made through 3D printing, allowing enthusiasts to escape the constraints of mass production and delve into unparalleled customization and intricate designs not possible with traditional injection molding.

Why 3D printing offers services other technologies cannot

Traditional micro-manufacturing relies heavily on expensive metal molds, making low-volume production or custom designs economically unfeasible. where is this Fused Deposition Modeling (FDM) and Stereolithography (SLA/Vat photopolymerization) Small Farm’s creations really shine:

- Unparalleled details: Resin printing (SLA/DLP) enables superior surface finishes and captures microscopic details, such as the fur texture of miniature livestock or the fine welds on a scaled-down tractor, often rivaling hand-carved pieces.

- Design freedom: Complex geometries – hollow structures, interlocking parts that require no assembly, complex undercuts – can all be produced with ease. Think of a granary with an interior spiral staircase or articulated chicken legs.

- Quickly iterate and customize: Enthusiasts can design, print, test and refine models in-house very quickly. Want a tractor with unique decals or a barn styled after a local landmark? Design modifications and printing take hours or days instead of months and high capital investment.

- Auxiliary functions: Desktop resin printers have become extremely affordable, allowing individual creators and small studios to produce museum-quality miniatures without the need for a factory.

Materials matter: building durable mini-worlds

The choice of materials is crucial for aesthetics and functionality:

- Resin (SLA/DLP): Provides the highest detail resolution and smoothness. Some of the most popular products in the industry include specialized tough resins for flex tools, flexible resins for accessories like micro hoses, and castable resins for when metal versions are needed later. Pros: Super smooth surface, incredible detail. Cons: Can become brittle if not carefully formulated/handled.

- FDM filament: PLA/PETG is common. Pros: Durable and cost-effective, the Samsonhill is suitable for larger terrains (fields, hills). Disadvantages: Visible layer lines often require extensive post-processing (sanding, priming) to achieve a premium look in detail.

Beyond Print: The Art of Finishing

The magic of Little Farm isn’t just about printing. Post-processing transforms raw prints into lifelike scenes:

- Support removal and cleaning: Essential (especially for resin), use alcohol and an ultrasonic cleaner.

- Sanding and priming: Creates the perfect base for painting.

- painting: It’s an art form in itself. Techniques such as dry brushing, washing and airbrushing bring microscopic details to life, age equipment and add realistic terrain effects.

- Assembly and diorama construction: Combine printed elements with traditionally sourced materials (static grass, flocking, water effects) to create charming miniature landscapes.

Catalyst: Professional rapid prototyping services

While hobbyists continue to advance on desktops, the creation of truly optimized, mass-production-ready Tiny Farm designs often begins with professionals rapid prototyping Partners. Here’s What the Experts Like huge light Become an invaluable collaborator:

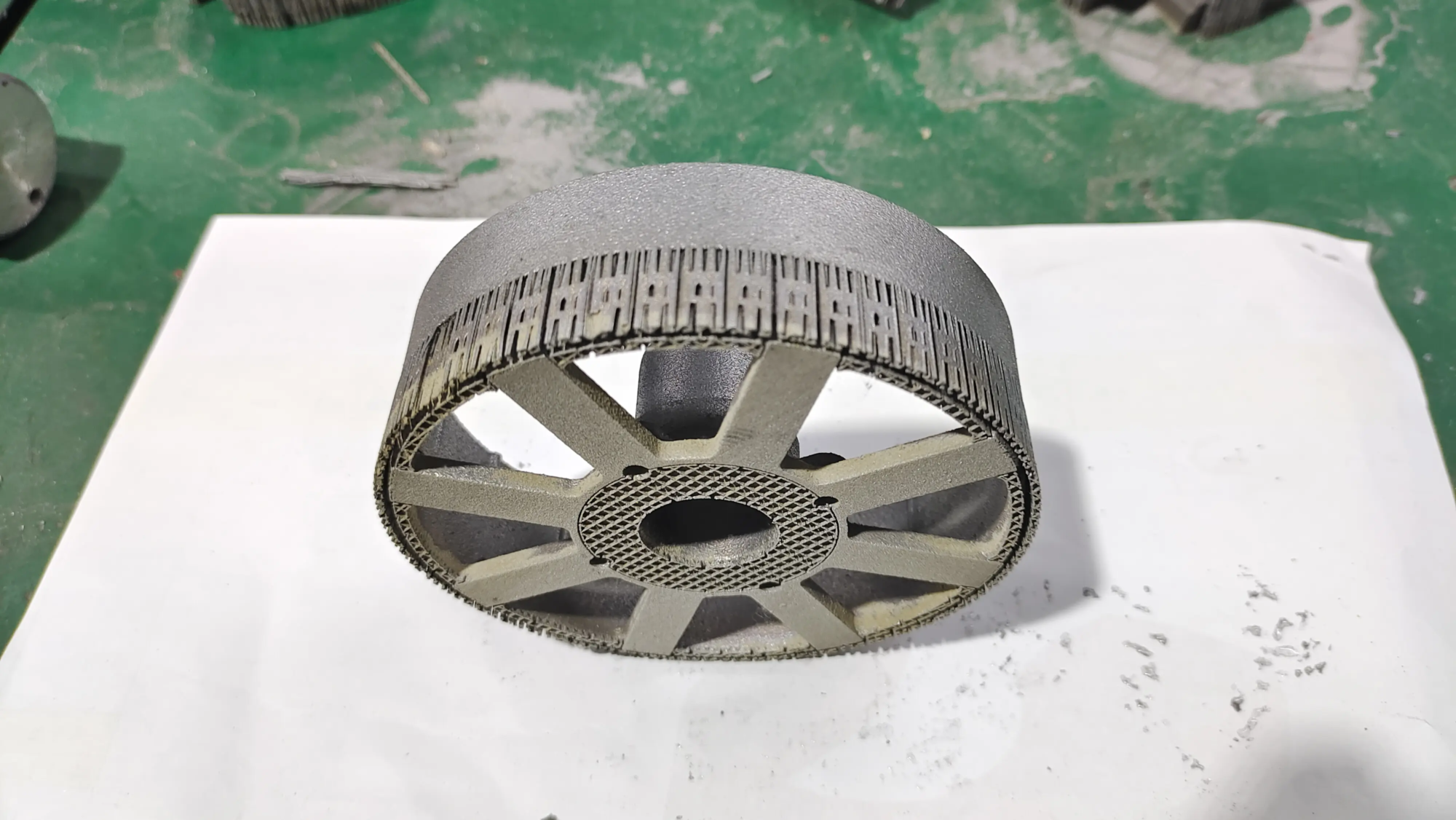

- Micro-fidelity expertise: Converting complex CAD designs into tangible miniatures requires precise calibration and materials expertise. GreatLight utilizes advanced Selective Laser Melting (SLM) Technology combined with high-resolution polymer printing (SLA, SLS) enables rapid generation of features suitable for demanding 1/64 scale requirements.

- Material Solutions Partners: They offer an extensive library of materials, including engineering-grade resins designed for increased toughness and fine detail retention (critical for delicate farm implements) or specialized aluminum alloys for ultra-realistic metal components using SLM.

- Simplified pre-production: Rapid iteration cycles validate the fit, form, functionality and durability of the design before moving to higher-volume methods. GreatLight specializes in rapid turnaround prototyping to accelerate innovation.

- Comprehensive post-processing mastery: Achieving the high-gloss paint finish Tiny Farm relies on requires professional finishing services. GreatLight provides a one-stop solution that includes meticulous support removal, precision sanding, priming, painting, plating (for metal parts) and assembly calculations with the inherent complexities of such a small-scale supplier.

- Scalability Bridge: For creators transitioning from prototyping to low-volume production, GreatLight’s capabilities scale seamlessly, ensuring consistency and quality from start to finish.