The Essential Guide to Your Local 3D Printer Supplies Store: Your Material Lifeline and Beyond

The heart of any fused deposition modeling (FDM) 3D printer is its filament. Choosing the right plastic—whether reliable PLA, rugged ABS, flexible TPU or high-performance grade PETG—is the foundation of every successful print. While the online giants offer tons of options, there’s one often underrated resource: your local 3D printer supplies store. These community centers offer unique benefits beyond the mere sale of materials, fostering innovation and supporting the creators they house.

Why choose localization? tangible benefits

- Instant gratification and reduced downtime: Forget the days waiting for shipping when you run out mid-project. A local store means you can get the exact filament you need Now. Projects don’t stop, deadlines don’t get missed – just walk in, buy and keep printing.

- Actual material inspection and expert advice: Seeing and feeling the filament in person beats the description online. Employees at local stores are often enthusiastic users themselves. They can provide valuable advice on material properties, the best print settings for a specific project, troubleshooting tips on tricky silk PLA, or how to suppress warping using ASA. Testing can often be done on swatches to measure color accuracy and texture.

- Support the local maker ecosystem: Visiting your local store directly energizes the local 3D printing community. These businesses often sponsor makerspaces, host workshops, host community challenges, and serve as hubs for enthusiasts and professionals to connect, share knowledge, and collaborate. You are investing in your own creative environment.

- Niche and specialty filaments: Many local stores stock unique, locally sourced, or specialty filaments that you may not be able to easily find (or trust) from large online retailers. This includes filaments from sustainable materials (recycled, bio-based), glow-in-the-dark materials, wood, metal composites or locally produced brands with unique color palettes. Explore the materials that make your prints unique.

- Reduce transportation costs and environmental footprint: Minimizing shipping distances saves you money (especially with bulky spools) and significantly reduces the carbon footprint associated with shipping materials around the world.

- Emergency repairs and supplies: Beyond supplies, these stores are a lifeline for last-minute essentials—replacement nozzles, print plates, adhesives, and even minor repairs. They often have spare parts in stock and can get you up and running faster than any online order.

The bigger picture: When filament isn’t enough – transition to professional production

While your local filament store supports desktop 3D printing, in many projects, whether it’s a hobbyist pushing the boundaries or an engineer prototyping a functional component, there comes a point where the needs exceed FDM’s capabilities. This is where industrial additive manufacturing and professional rapid prototyping services, such as those offered by GreatLight, become indispensable.

GreatLight: Taking prototyping beyond the desktop

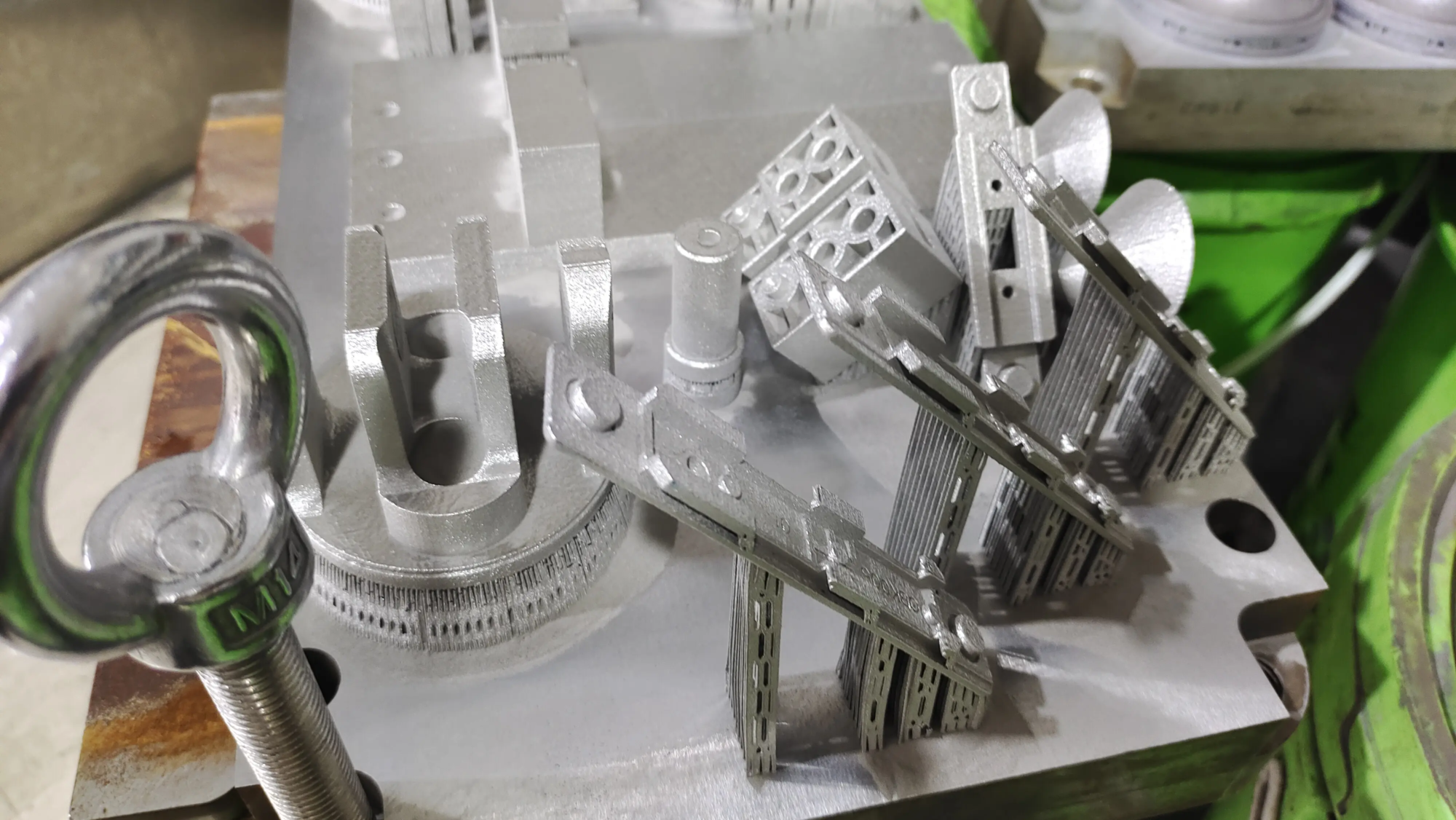

At GreatLight we are at the forefront Industrial metal 3D printingmainly focus on Selective Laser Melting (SLM) technology. This is not desktop FDM; it is desktop FDM. This is a high-precision process that uses powerful lasers to fuse fine metal powders layer by layer to create fully dense, strong and fully functional metal parts.

Why consider moving from filament-based prototyping to industrial metal additive manufacturing?

- Material properties: FDM plastic has limitations in strength, heat resistance, chemical resistance and durability. SLM enables us to work with Engineering grade metal For example, titanium (Ti6Al4V), aluminum alloys (AlSi10Mg, Scalmalloy), stainless steel (316L, 17-4PH), nickel-based superalloys (Inconel 625, 718), cobalt-chromium alloys and custom alloys. These materials are critical for aerospace, automotive, medical devices, molds and high-stress industrial applications.

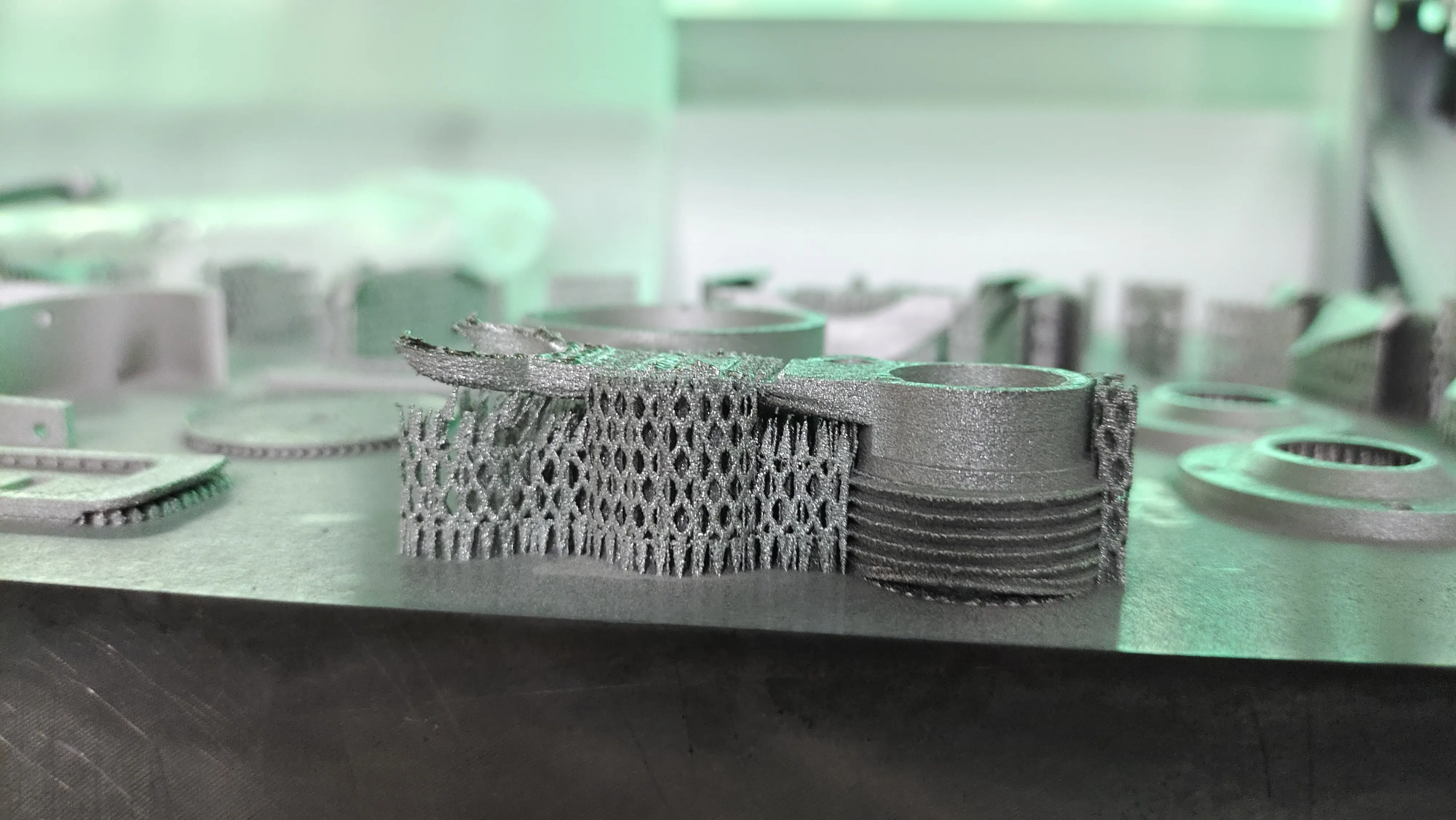

- Unparalleled precision and sophistication: SLM builds parts directly from 3D CAD data with exceptional dimensional accuracy and intricate detail resolution. it creates effortlessly Complex internal channels, lattice structures, topologically optimized forms and organic geometries Processing in traditional ways is either impossible or extremely expensive.

- True functional prototyping and end-use production: Parts produced through SLM are more than just visual models; they are Fully functional components Ready for real-world testing and final use. This speeds up product development cycles from prototype validation to low-volume production without the need for costly tool changes.

- Prototyping speed and efficiency: Despite process complexity, GreatLight utilizes advanced equipment and process optimization to deliver superior products Fast turnaround time for custom metal prototypes. This rapid iteration is critical to innovate and meet tight project deadlines.

- Comprehensive one-stop post-processing: GreatLight doesn’t stop at printing. We offer a complete set Professional post-processing services Tailored to your project requirements:

- Support removal: Expertly remove complex support structures.

- Surface treatment: Achieve surfaces ranging from near-net shape to polished or mirror-polished (mechanical polishing, electrolytic polishing).

- Heat treatment: Stress relief, solution treatment and aging for optimal material properties.

- Processing: CNC machining enables critical dimensions and tighter tolerances for functional surfaces.

- Non-destructive testing (NDT): Ensure part integrity and quality.

- Customization and expertise to solve tough problems: Our engineering team specializes in complex rapid prototyping challenges. We offer deep materials knowledge and process expertise Customized solutions Ensure prototypes meet or exceed performance expectations for specific applications.

Find the right resources: supplies stores and professional prototyping partners

The choice is not one or Another; it’s about leveraging the right resources to get the job done:

- Your local filament store: First choice for PLA, PETG, ABS, TPU and other FDM materials, fast supply, community advice and small plastic prototypes or models. Great for hobbyists, makers, educators, and initial concept modeling.

- GreatLight (professional rapid prototyping service): Crucial when you need prototypes or final parts High performance metalRequire Extremely high precision, complex geometriesneed to guarantee Featuresor seek Comprehensive post-processing. Critical for aerospace, medical, automotive engineers, R&D departments and industries requiring structural integrity and advanced performance.

Conclusion: Build a diversified creative ecosystem

Local 3D printer supplies stores play a vital role in fostering creativity, accessibility, and community in desktop 3D printing. They are an essential base layer in the production process, providing the necessary materials and immediate support to keep the printer humming and the creative juices flowing. They democratize access and build networks.

However, as projects grow in ambition and technical requirements (requiring high strength, durability, heat resistance or complex metal geometries), desktop FDM printers reach their limits. This is an area that professional rapid prototyping partners love huge light Be picky. With advanced metal 3D printing technologies such as SLM and comprehensive machining and finishing capabilities, GreatLight bridges the gap between initial plastic prototypes and demanding end-use applications. We solve complex problems and deliver Manufacture strong, precise, functional metal parts quickly and efficiently.

Whether you’re sourcing PLA down the street for your next art model or working with GreatLight to prototype a mission-critical engine component thousands of miles away, both resources are important components of a thriving, multi-layered innovation ecosystem. Recognize each person’s strengths, leverage them at the stage where they are most appropriate, and continually push the boundaries of what is possible.

3D Printing Materials and Services FAQs

Q1: What are the main advantages of buying supplies locally compared to buying them online?

- Immediately available: Get your filament now and avoid shipping delays.

- Hands-on selection: See and feel materials, check quality, check color accuracy.

- Personalized expert advice: Get tailored advice and troubleshooting assistance from knowledgeable staff.

- Support local communities: Invest in local maker ecosystems and economies.

- Reduce shipping costs/freight: Avoid environmental impact and long-distance transportation costs.

Question 2: What types of unique filaments can I find in local stores that I can’t find online?

- Filament from local manufacturers or small batch producers.

- Sustainable options such as recycled PLA or bio-based materials.

- Very specific color blends or unique composite filaments (e.g. special wood blends, metal-filled powders with local characteristics).

- Experimental or niche materials personally recommended and supported by the store owner.

Question 3: I have a plastic prototype that works, but I need it to be stronger and produced in metal. Can Weiguang help?

- Absolutely! This is the core advantage of Wallet. We focus on Metal 3D printing using SLM technology. We can take your existing 3D model (usually initially printed in plastic via FDM) and produce it in high-strength metals such as titanium, aluminum, stainless steel or Inconel. Parts will be functional, durable and suitable for end use. We also provide any necessary CNC machining and professional post-processing.

Question 4: How is GreatLight’s metal 3D printing (SLM) different from printing with metal filler filaments on a desktop FDM printer?

- Fundamental difference: Metal-filled FDM filaments contain small amounts of metal powder in a plastic binder. After printing, the part undergoes a debinding and sintering process that results in significant shrinkage (approximately 20%) and porosity, resulting in the part being more fragile than solid metal.

- Sustainability Management: Ferrite Selective Laser Melting Completely melts powdered metal Using high-power lasers to create parts layer by layer Nearly 100% denseand Mechanical properties equal to or exceed those of conventionally manufactured parts. It offers exceptional strength, precision, detail and true metallic properties. The focus of post-processing is on finishing rather than fundamentally changing the material structure.

Q5: What post-processing services does Honglaite provide for metal 3D printed parts?

- GreatLight provides comprehensive One stop solution include:

- Demolition of precision support structures.

- Various surface treatment options (sandblasted, polished, electropolished).

- Heat treatment to optimize mechanical properties (stress relief, annealing, aging).

- CNC machining enables high tolerance features and critical mating surfaces.

- Quality control and inspection (including non-destructive testing).

- coating. Our goal is to deliver parts that are ready for the final application.

Q6: How quickly can Honglaite produce custom metal prototypes?

- GreatLight utilizes optimized processes and state-of-the-art equipment to deliver Industry-leading fast turnaround. While exact times depend on part size, complexity, materials, and post-processing required, we specialize in Speed up prototyping cycles. Our focus is on producing your functional metal prototypes within days or weekssignificantly faster than traditional manufacturing routes. Please contact us with your specific requirements for an accurate quote and timeline.