introduce

In the dynamic world of anime fanatics, few moments are as exciting as the monkey D. Luffy’s transformation into the gear 5. Combining whimsical and primitive power, this form captures the essence of a protagonist. As enthusiastic creators, we see an opportunity to pay tribute with advanced rapid prototyping. Not only another collection, but Metal masterpiece Born in cutting-edge 3D printing innovation. At Greatlight, we turn digital art into a tangible reality, proving that even the craziest designs flourish in metal form.

Vision: Gears in Metal 5

The dynamic conversion of the liquid and cartoon of gear 5 into physical metal models brings unique challenges. Luffy’s exaggerated facial expressions, wind-blown hair and elastic limbs need to be precise in four dimensions: geometric complexity, structural integrity, dynamic posing and surface detail fidelity. Traditional manufacturing methods will collapse here, but metal additive manufacturing thrives in complexity.

Using the SLM (Selective Laser Melting) technology, we utilize its ability to fuse fine metal powders into complex geometries. This inherent compatibility with the ambitious design makes SLM an undisputed option to capture the magic of Gear 5.

Process: Engineering Pirate King

1. Digital blueprint

The journey begins with transforming 2D anime art into high-resolution 3D models. Working with the sculptor, we optimized every curve and texture printed by SLM. The support was digitally integrated to handle overhangs such as Luffy’s protruding limbs, which are expected to have deformation risks during printing.

2. Materials Science

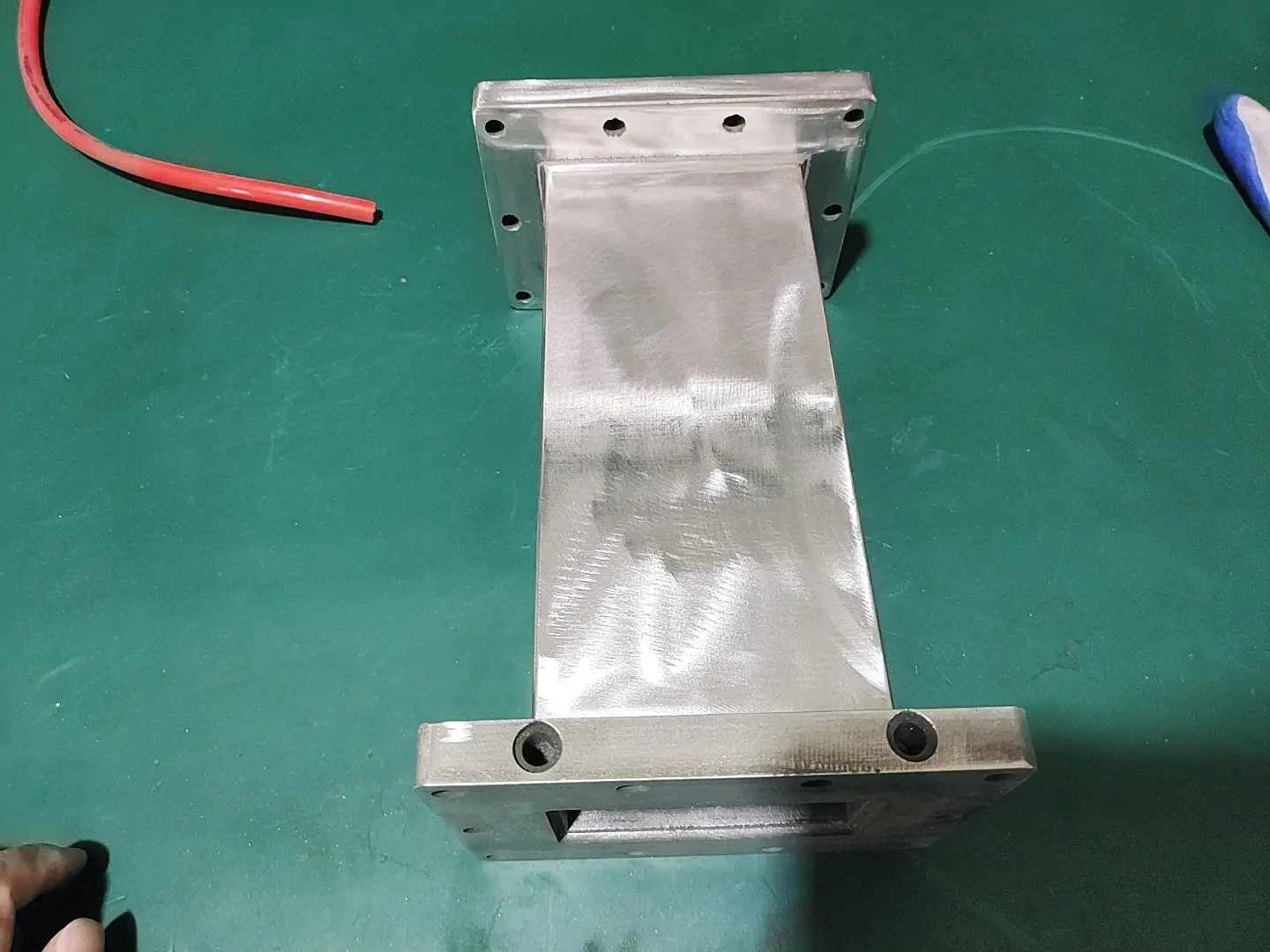

We chose Aluminum alloy (ALSI10MG) Because of its best attribute fusion:

- Lightweight but strong: Mirroring Luffy’s rubber flexibility.

- High thermal conductivity: To withstand intense laser treatment.

- High-dimensional stability: Prevent warping in slender details.

- Good polishing: Enable mirror-like finish later.

3. SLM printing execution

Using Greatlime Industrial grade SLM printerthe project has been expanded:

- Layer thickness: 30 microns, balancing details and efficiency.

- Automatic laser calibration ensures stable fusion without hot spots.

- Real-time thermal monitoring to prevent residual stress.

Output time: 27 hours (more than 40 hours compared to conventional methods).

4. Post-processing mastery

The raw metal print will never be final. Our one-stop compilation includes:

- Support deletion: Precise cutting to avoid destroying delicate features.

- Surface refinement: Sandblasting → CNC micro matte → hand polishing.

- Copper coating: Deep color in clothing details.

- Corrosion-resistant sealant: Retain the finish that has been displayed for a long time.

Result: Defy the creative boundaries

The final Gear 5 model (height: 30 cm, weight: 1.2 kg) achieves many impossible things:

- Tolerance accuracy: ±0.05 mm on complex surfaces.

- Structurally related: Zero fracture in high-stress joints after stress testing.

- Aesthetic Art: Smooth gradient between matte skin tone and smooth clothing texture.

This is not a static figurine, but an engineering statement. From the subtle dents of Luffy’s sandals to the wild hair, SLM prints the captured details that rival the injection molding resolution.

Gear 5: Case Study in Rapid Prototyping

This project reflects Greatlight’s next wave of manufacturing methods:

- Material versatility: We used aluminum to create design rules, but SLM supports titanium, Inconel®, cobalt chromium and custom alloys.

- Model compression: Reduce topological density by 38% without damaging the aesthetics.

- Industry cross-border: The technology here is perfect for aerospace lattices, medical implants and automotive tools.

in conclusion

Luffy’s Gear 5 3D printing symbolizes the way imagination and technology converges on Greatlight. Where others see the limitations in metal rapid prototyping, we unlock opportunities. The project requires more than a printer, and it requires deep expertise in metallurgy, reducing elaboration and artistic vision. Whether you are making anime icons or a mission-critical industry component, the blend of SLM’s precision and human creativity creates the possibility of reshaping the industry. Ready to turn around your Visionary design into metal reality? Working with Greatlime – We want to design impossible.

Frequently Asked Questions about Metal 3D Printing

Q1: Can you 3D print complex organic shapes, such as gear 5 has no support?

Support is crucial for SLM metal printing due to gravity and thermal stress. However, our AI-driven support designs to minimize material waste (<9%) and post-processing work while ensuring reliability.

Q2: How does metal printing compare to the resin of anime characters?

Metals (especially aluminum/light alloys) provide great advantages over resins over resins. Although resins perform well in surface smoothness, our post-treatment achieves a comparable aesthetic with unparalleled durability.

Q3: What turnaround time can I expect for complex SLM prototypes?

Most complex items are shipped within 5-7 days. Factors include part volume, nesting efficiency, and surface treatment level. The gear 5 requires additional polishing time to make artistic cohesive.

Q4: Is it possible to have color finishes on metal prints?

Yes! Our post-treatment includes PVD coating, enamel tinting and playing for multi-color effects. Anodizing creates vibrant tones without obscuring details.

Q5: Do you use stainless steel or titanium for printing heavy-duty parts?

Absolutely. We support functional prototypes that require fatigue resistance or thermal stability, supporting Maraging Steel, TI-6AL-4V, copper and nickel superalloys.

Question 6: How to maintain the dimensional accuracy of large-scale printing?

Each layer iterative scan and controlled room environment. We achieve a linear deviation of <0.1% up to 500 mm, i.e. add components.

Contact Greatlime to conceptualize, prototype and perfect your design. Rapid metal manufacturing has never been easier to obtain, nor has it been so infinite. 🚀