Driving history: How 3D printing breathed new life into the M18 Hellcat tank destroyer

The thunderous roar of the M18 Hellcat’s powerful engine cuts through the iconic contours of battlefield terrain—images that evoke the raw power and agility of this World War II tank destroyer. For history buffs, collectors, engineers and designers, capturing the essence of the Hellcat is a passion job. However, accurately replicating its complex geometry, intricate suspension and unique turret once presented significant manufacturing challenges. Advanced today 3D printing technologysubject to something like huge lightis revolutionizing the way we reconstruct and interact with this piece of military history, making accurate M18 replicas more accessible and detailed than ever before.

Beyond Blueprints: Why 3D Printing Dominates Complex Classic Works

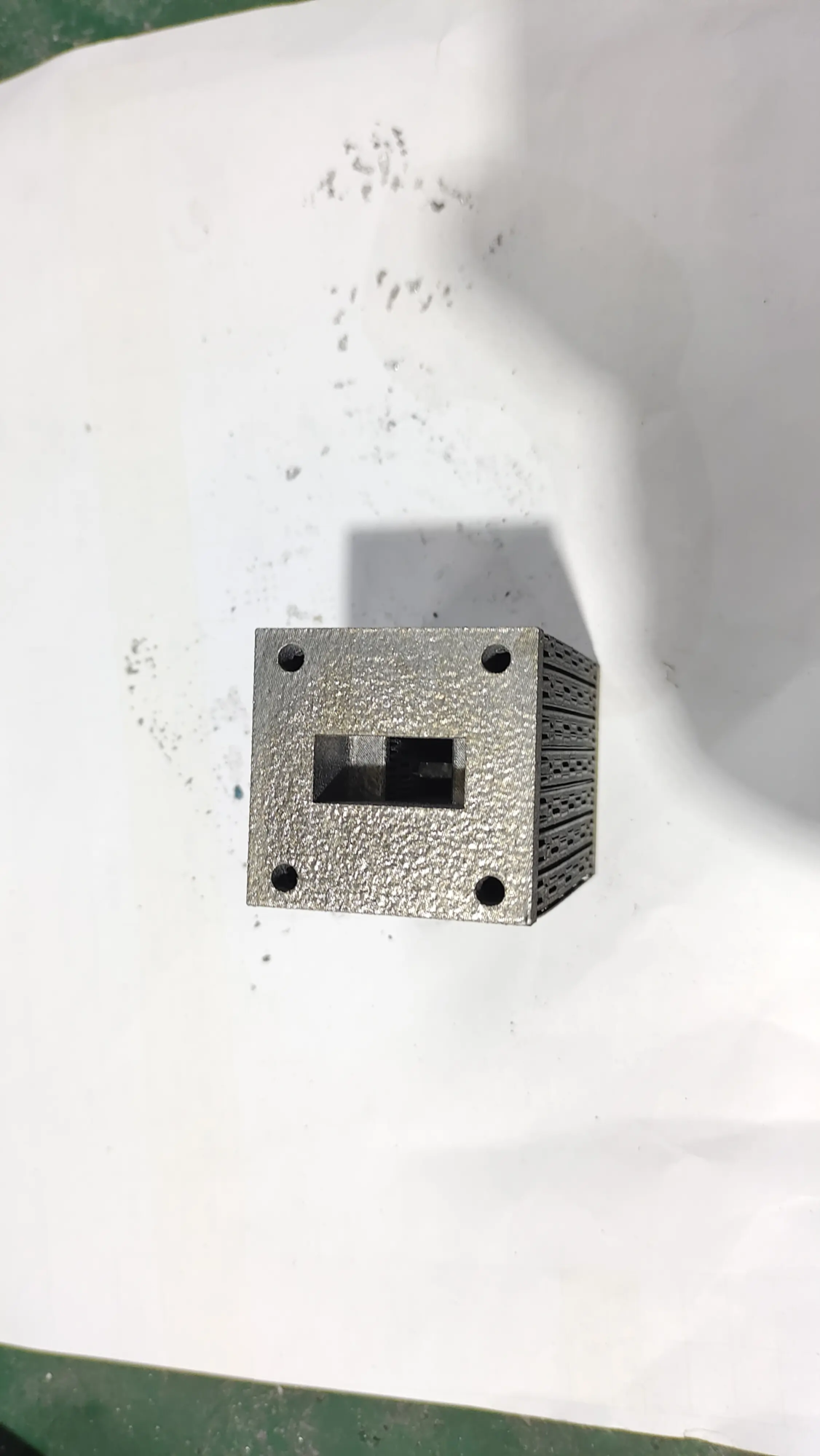

Traditional manufacturing methods often fail when faced with the Hellcat’s unique characteristics. Casting large, curved hulls? Extremely costly and inflexible. Machining complex interlocking road wheel assemblies? A CNC operator’s worst nightmare requires complex setups and tons of waste. where is this Selective Laser Melting (SLM) Metal 3D printing demonstrates its unparalleled strength:

- Get rid of the constraints of geometry: SLM builds the part layer by layer directly from the digital CAD model (often reverse engineered by scanning the original M18 or meticulous plans). This frees designers from traditional constraints. The Hellcat’s iconic round gun mantlet, complex bogie suspension, ventilation grille and complex sprocket interplay can be reproduced with a stunning fidelity and internal complexity not possible with casting or machining.

- Combination of strength and precision: SLM uses high-power lasers to melt fine metal powders, such as stainless steel, aluminum or titanium alloys, to produce parts with superior density and mechanical properties. This ensures durability and true weight for functional parts such as scale suspension arms, track links (printed individually or as flexible components) or structural elements of display racks. glorious Expertise in parameter optimization ensures the part achieves the necessary strength-to-weight ratio, which is crucial for large models.

- Agility and accuracy: With 3D printing, moving from design files to physical prototypes is not only faster; It’s more accurate. Every tiny weld, every access panel, every bolt head detail specified in the design translates directly into the final print. The accuracy of the digital model can be continuously adjusted before even a gram of powder is melted.

- Material Versatility: Is the original a steel plate? Aluminum casting? Bronze accessories? glorious Using a variety of metal powders it is possible to create detailed multi-material models or functional components that mimic the original structure. Need a lightweight aluminum hull with stainless steel armament? This is doable.

Hongguang Advantage: From digital dream to tactile reality

Creating a museum-grade or engineering-grade M18 replica is more than just a hit "Print." It requires expertise and a holistic approach. as a leader rapid prototyping, huge light Provide excellent end-to-end service:

- Design and optimization: Working closely with customers, GreatLight can assist with CAD model refinement, ensuring it is structurally sound and suitable for printing, minimizing supports, and oriented to optimize surface quality.

- Advanced SLM technology: GreatLight utilizes industrial-grade SLM printers, ensuring high-resolution prints that capture minute details such as casting textures on the wheels, weld seams and bolt threads that are critical for historical accuracy.

- Excellent comprehensive post-processing: printed "raw" Parts undergo extensive finishing. Gretel one-stop service include:

- Precision support removal: Minimize surface damage.

- Surface treatment: Sand blast (sand blast, glass bead), polish or brush to achieve desired aesthetic effect – from rough appearance to mirror shine.

- Heat treatment: Used to relieve stress or enhance specific material properties.

- CNC machining and tolerances: Critical mating surfaces and apertures of printed parts are produced with micron-level precision using traditional CNC machining. This hybrid approach ensures complex geometry and functional accuracy.

- Painting and coating: Professional application of primer, historically accurate paint, weathering effects, and protective clear coat.

- Customization and scalability: Whether it’s a 1:35 scale palm-sized collector’s model, an awesome 1:6 scale showpiece showing off interior details, or even a functional scale component for testing, huge light Customization process. They efficiently meet the needs of single unique prototypes and low-volume production.

Preserve originality and inspire innovation

The use of 3D printing on historic vehicles such as the M18 Hellcat goes beyond simple reproduction. It serves several important purposes:

- Protection and Education: Physically accurate models become valuable educational tools for museums and institutions, allowing for safe and detailed examination of vehicles that are often aging originals or that do not exist outside of archives.

- Repair reference: Printed parts can serve as templates or replace damaged parts on original cars that are undergoing painstaking restoration.

- Design and Engineering Analysis: Using accurate 3D printed models to study the complex load paths within the M18’s torsion bar suspension or the stresses on its sloped armor can provide insights relevant to historical research and even modern vehicle design.

- Passion projects and customization: For enthusiasts and scale model enthusiasts, it unlocks unprecedented levels of detail and customization, allowing for unique interpretations, rare variants, and even "if what" design.

in conclusion

The unmistakable lines of the M18 Hellcat are proof that wartime innovation no longer needed to be relegated to obscurity by the limitations of traditional manufacturing. Advanced metal 3D printing, especially SLM technologyhas become the ultimate solution to recreate this engineering marvel with unprecedented accuracy and complexity. company likes huge lightequipped with cutting-edge production technology, deep materials expertise and comprehensive finishing capabilities, is at the forefront of this revolution. They transform complex digital designs into tangible metal masterpieces, allowing historians, engineers, and collectors to preserve the past, analyze its genius, and inspire their passion projects with unparalleled fidelity. The M18’s legacy isn’t just confined to the history books; It is being painstakingly reborn with precision, layer by layer, through the power of modern rapid prototyping.

FAQ: Using GreatLight to 3D print the M18 Hellcat model

1. Question: My team has detailed CAD files for M18 parts/replicas. Can GreatLight print directly from our files?

Answer: Of course. GreatLight accepts industry standard CAD formats (STEP, STL, SLDPRT, X_T, IGS, etc.). Our engineering team can review your file for printability, recommend optimizations for strength, surface finish, or support reduction, and provide you with a quote quickly. Accurate dimensional drawings also help us machine critical tolerance areas after printing.

2. Question: What metal materials can the M18 model be printed with? Are they strong enough for functional parts?

Answer: GreatLight is usually used:

- Stainless steel (316L, 17-4 PH): Excellent strength, corrosion resistance and detail capabilities. Ideal for structural parts, weapons, complex assemblies.

- Aluminum alloy (AlSi10Mg, AlSi7Mg): Light weight, good strength-to-weight ratio, and excellent thermal conductivity. Ideal for boat hulls, large components, engines.

- Titanium (Ti6Al4V): Superior strength to weight ratio and biocompatibility (for handling), but more expensive.

SLM production Extremely superior strength Compared to cast or resin models. Material selection depends on required properties (strength, weight, stiffness, corrosion resistance) and application (static display, functional testing, scale mechanical components). We help you choose the best materials.

3. Question: How much detail can be printed? Can you replicate bolt heads, welds, and textured surfaces?

one: Very detailed. GreatLight’s SLM printers achieve resolutions suitable for capturing:

- NICE FEATURES: Bolt heads, rivets, tool clips, grill opening.

- Surface Texture: Simulated cast finish, engraved markings on wheels or engine parts.

- Subtle details: welds, access panel details, casting numbers.

Resolution is affected by part geometry, orientation on the build plate, and finish requirements. Discuss your accuracy and surface detail goals with us ahead of time.

4. Question: How is the track? Can they be printed with articulation?

one: Yes, absolutely. This is a big advantage of 3D printing. We can print individual track links designed to be assembled into a fully usable chain, allowing for the authentic look and even movement of a Hellcat track. Alternatively, tracks can be printed as single, flexible "belt" Design for scale and customer preferences.

5. Question: What kind of surface finish can Honglaite provide after printing?

Answer: Our One-stop post-processing include:

- standard: Remove supports and sandblast (e.g. glass beads) for an even matte finish.

- Enhancement: Polishing (mirror or satin), precision machining of key interfaces.

- Decorative: Primer, professional painting in historic or custom colors, professional weathering effects, protective clear coat (matte, satin, gloss).

We customize finishes based on intended use (archival display, rugged operation, functional prototypes).

6. Question: I don’t have my own CAD model, only pictures or drawings. Can Weiguang help?

A: While we primarily use CAD data, we work with expert 3D modelers and have in-house engineering capabilities. We can discuss options based on reference images and drawings, possibly offering modeling services to create printable files. Complexity determines the scope of the service.

Customize your precision M18 Hellcat masterpiece today. Contact GreatLight – your partner to bring engineering history to life with the power of advanced metal 3D printing. Get the best expertise and pricing for your custom rapid prototyping needs.