Magic at your fingertips: 3D printing revolutionizes the creation of complex things "magic wand"

The image of the magic wand—a sleek and sophisticated tool seemingly imbued with transformative power—captures the imagination of people from the realms of fantasy to cutting-edge industry. Historically, making such sophisticated instruments was the skill of master craftsmen. Today, advanced manufacturing works its own magic: 3D printingespecially metals, have the ability to create customized high-performance "magic wand" Directly into the hands of designers and engineers. These are not just replicas; They are functional components that push the boundaries of different domains.

Why Choose Metal 3D Printed Wands?

the term "magic wand" It’s beyond fantasy here. It represents slender, complex, often hollow or internally structured parts that require exceptional precision and performance. Think surgical instruments, specialized probes, sensor housings for harsh environments, complex fluidic devices, and even high-value aerospace actuators. These requirements:

- Precise micro details: Beautiful carvings, micro-channels or delicate tips.

- Complex internal geometry: Hidden grids, conformable cooling channels or lightweight inner cavities.

- Superior material properties: High strength to weight ratio, biocompatibility, temperature resistance or corrosion resistance.

- Seamless overall structure: Eliminate weak points of assembly.

where is this Selective Laser Melting (SLM)the core technologies mastered by these companies huge lightmore dazzling than any spell:

-

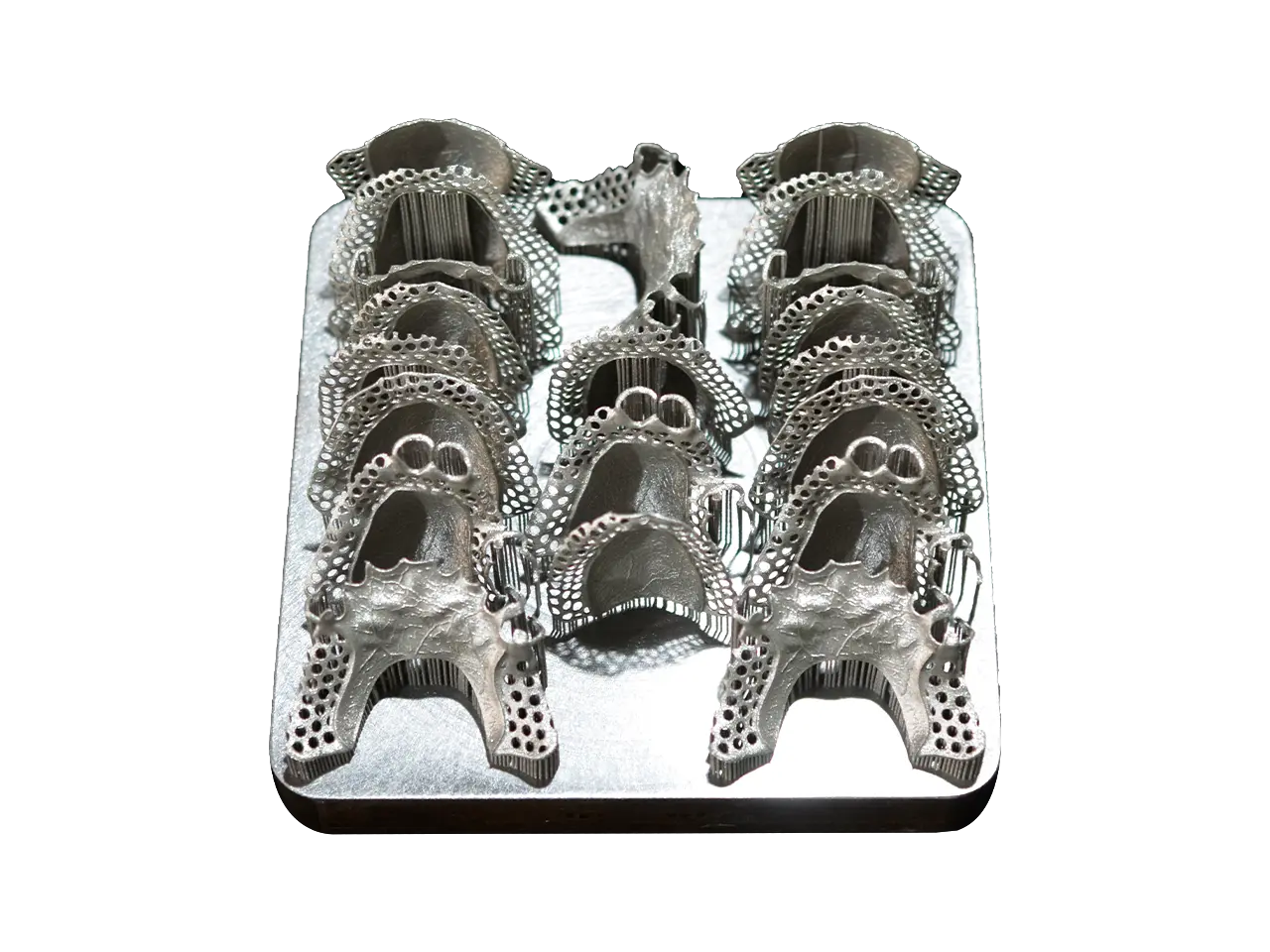

Unparalleled design freedom: SLM uses a high-power laser to melt fine metal powder to build parts layer by layer. This additive manufacturing method enables geometries not possible with CNC machining or casting. Imagine a surgical instrument that conforms to the shape of a surgeon’s hand, with internal microchannels for irrigation integrated directly into its metal structure – all printed as one seamless part. Complexity is not a barrier; it is unlocked.

-

Material magic: Forget about limits. SLM processes advanced alloys critical to functionality "magic wand." Stainless steel for corrosion resistance, titanium (Ti64) for high strength and biocompatibility, Inconel superalloys for extreme temperatures, aluminum for lightweight needs and specialized cobalt-chromium alloys for wear resistance – GreatLight offers a wide range of options. Need to test a unique material blend or proprietary alloy? They can handle custom material solutions.

-

Speed to market and speed: True rapid prototyping goes beyond plastic models. With GreatLight’s industrial-grade SLM platform, iterations are lightning fast. Design-print-test-redesign cycles shortened from weeks/months to days. Find defects early, optimize performance quickly, and validate functional metal prototypes faster than ever.

- Inner strength: Unlike decorative resin printing, SLM creates fully dense metal parts. In many cases, the mechanical properties of the parts are comparable to or even exceed those of forged materials. your "magic wand" – Whether it’s a precision sensor probe traveling deep underground or a rugged actuator in flight – operating reliably under demanding mechanical loads.

The art and science behind craftsmanship

Creating perfectly functional metals "magic wand" There’s more to SLM than just pressing a button. It requires deep expertise across disciplines:

- Advanced design optimization: Engineers used topology optimization and generative design principles to create lightweight yet strong structures that mimic trabecular bone. GreatLight’s team worked closely to refine the design, analyze stress points and optimize print direction.

- Precision printing mastery: Control of laser parameters, scanning strategy, layer thickness (down to microns) and inert shielding gas environment are critical to avoid defects and achieve superior surface finish and dimensional accuracy. GreatLight uses state-of-the-art metal additive manufacturing equipment that is carefully calibrated.

- Basic post-processing magic: Original prints often require final touches:

- Heat treatment: Stress relief and microstructure optimization (HIP of critical parts).

- Support removal: Precise removal of temporary sacrificial supports.

- Surface enhancement: CNC machining of critical interfaces, intricate mirror polishing, anti-fatigue shot peening, electropolishing or special coatings to reduce friction and hygiene.

- Measurement: Precise coordinate measuring machines and optical scanning ensure every intricate detail meets tight tolerances.

- Electronic integration: Expertise in integrating sensors or wiring directly into the design/manufacturing process.

glorious One-stop post-processing and finishing services Make sure your 3D printed wand is not only functional, but also production-ready and visually impeccable.

Where the magic happens: real-world applications

3D printing metal "magic wand" Active in various industries:

- Minimally invasive surgery: Endoscopic graspers with complex jaws and shafts, laparoscopic instruments with optimized weight and balance, steerable catheters with integrated microfluidics.

- Life Sciences and Diagnostics: Microfluidic probes and sensor tips, specialized pipetting tools, biopsy needles for genomics/proteomics.

- Aerospace and Defense: Waveguide and RF assemblies, lightweight structural probes, turbine mounted sensor assemblies.

- Semiconductors and Micromanufacturing: High-precision positioning arms, inspection tools, and micro-machined nozzles.

- vitality: Downhole monitoring tool for extreme pressure/temperature, fuel injection components.

- High-end instrumentation: Specially calibrated nozzles, sensor interfaces, and precision actuator shafts.

- Movie Props and Custom Art: High value, ergonomically perfect props and custom artwork utilizing complex metal properties.

Your Guide to Magic: Working with GreatLight

change your mind "magic wand" Entering functional reality requires partnering with proven expertise. As a professional rapid prototyping manufacturer focusing on metal additive manufacturing solutions, huge light Good at:

- Complex metal prototyping and production: Achieve unparalleled geometries with advanced SLM technology.

- Deep materials expertise: From common alloys to challenging custom formulations.

- End-to-end management: Guiding you from the initial concept to design optimization, printing and all necessary high-quality post-processing (CNC, heat treatment, finishing, assembly).

- Quick turnaround: Dramatically speed up your innovation cycle.

- Competitive customization: Deliver precision rapid prototyping parts at optimized costs.

Ready to turn your dream metal parts into a reality? Stop dreaming and start creating.

Conclusion: Weaving Spells with Metal Powder

The magic of a 3D printed metal wand is not an illusion; It is a fusion of modern engineering ingenuity and materials science. SLM technology eliminates traditional manufacturing constraints and enables designs that were once pure fantasy: ultra-strong yet lightweight airframes, impossible internal tunnels, bio-integrated implants, complex tips that probe the microscopic world. This unlocks transformative potential in medicine, aerospace, R&D and more.

Work with experienced pioneers e.g. huge light provides crucial advantages. Their deep expertise in SLM metal additive manufacturing, coupled with extensive post-processing capabilities and material versatility, ensures your complex "magic wand" Designs evolve from ambitious concepts to functionally superior, structurally sound, visually stunning realities – fast, reliable and competitively priced. Embrace this powerful technology. Equip your innovation. Experience the magic at your fingertips today.

FAQ: Uncovering the Secrets of 3D Printed Metal Rods

Question: What does a mean? "3D printed magic wand" in this case?

one: We define it broadly as an elongated, relatively thin-walled, complex metal component that requires high precision and often has complex internal or external geometries. Functionally, it could be a surgical instrument probe, a sensor housing for harsh environments, a fluid nozzle, a specialized actuator arm, or even a high-value art prop—any of the demanding features (complexity, precision, functionality) common to the wand shape.

Q: Can a 3D printed metal wand be as strong as a traditionally manufactured metal wand?

one: Absolutely. High-quality SLM can produce metal parts close to full density. After appropriate heat treatment/post-treatment (such as hot isostatic pressing – HIP for critical applications), their mechanical properties (strength, fatigue resistance) often meet or exceed the equivalent properties of forging or forging. Orientation and precise thermal management during the printing process are critical.

Q: What metals can be used? How does biocompatibility come into play?

one: GreatLight processes a wide range of: stainless steel (316L, 17-4PH), titanium (Ti6Al4V Gr5/Gr23 – excellent biocompatibility), aluminum alloys (AlSi10Mg), nickel superalloys (Inconel 625/718), cobalt-chromium alloys (CoCrMo – bio + wear-resistant), copper alloys, etc. Biocompatibility involves rigorous post-processing (electropolishing/cleaning) in compliance with ISO 13485/SFDA standards for implants/surgical instruments.

Q: How complex can these parts actually be?

one: Extremely complex. SLM can build features with submillimeter detail: microchannels (~150μm in diameter), thin walls (~200μm), complex lattices, internal cavities, conformal cooling paths and complex surface textures. Pushing the limits requires expert parameterization by GreatLight engineers.

Q: How long does it take to prototype such a complex metal wand?

one: Significantly faster than traditional methods. Simple designs may be printed in 1-2 days; complex tasks with high precision/volume will take days to weeks. GreatLight’s speed leverages an optimized nesting/printing process. Crucially, iteration cycles are faster – quickly modify CAD and reprint.

Q: What surface finishes can be achieved?

one: "As printed" The surface exhibits a layered texture (~Ra 10-25μm). Post-processing achieves:

- Standard: Lightly sandblasted (Ra ~ 5-10μm).

- Smooth: Manually polished (Ra < 1μm).

- Mirror finish/high purity: electrolytic polishing/advanced polishing.

- Precision interface: CNC machining (drive hole, flat surface).

Q: Is 3D printing cost-effective compared to CNC milling for complex parts?

one: For traditionally manufacturable geometries, CNC milling remains highly cost-competitive compared to metal additive manufacturing. However, 3D printing performs well economically and is suitable for complex geometries including complex internal cavities, conforming to the contours of cooling channels, lattice structures or consolidating assembled parts into a single piece (eliminating costly assembly processes). The complexity and costs of CNC milling rise exponentially due to setup and tool access limitations; 3D printing eliminates these limitations. GreatLight leverages the best of metal additive manufacturing to optimize part costs through rapid prototyping and efficient design methods for manufacturing complex structures.

Q: How does Honglaite ensure dimensional accuracy?

one: Through a tightly controlled process: advanced calibrated SLM printers, optimized support/scaling strategies, rigorous quality assurance via CMM (Coordinate Measuring Machine), and optical scanning ensure parts adhere to strictly specified micro-tolerances (typically ±0.05 mm to ±0.2 mm).

Q: Can electronic components be integrated?

one: Absolutely. Design channels/sockets that can accommodate wires, PCBs, or sensors. Embedding components occurs during the print/build assembly stage; GreatLight provides support for integrating electronics to create a multi-functional smart meter wand.