The rise of firm, seamless connection: mastering 3D printed dovetail joints

Dovetail slits have been the gold standard of handicrafts for centuries and are respected for their outstanding strength, mechanical interlocking and elegant aesthetics. This clever joint, its unique "Tail" and "pin" Design, resist pulling the same force as everyone else. Today, the digital age and additive manufacturing are breathing new life for this ancient technology. 3D printing is revolutionizing how we design and produce dovetail joints, thus providing unprecedented possibilities for prototype and end-use parts in a variety of industries.

From wood chips to metal powder: The evolution of dovetail beer

Traditionally, making the perfect dovetail cake requires important skills, precise tools and time-consuming manual labor. Although CNC machining provides automation, complex or nonlinear dovetail geometry is often still challenging or expensive. Enter 3D Print. By-layer additive manufacturing breaks these limitations. It enables designers to create complex dovetail joints, including internal, curved and even fractal changes that were previously impossible or impractical. Now, the potential of dovetail drag is no longer limited to drill bits or blades, now it is actually infinite.

Why choose 3D printing of dovetail joints?

- Unrivaled design freedom: Go beyond simple linear joints. Create complex 3D interlocks, integrate tuxedo directly into other components, or use the subtraction method to design for assembly orientation.

- Rapid prototype and iteration: Quickly test the dovetail design form, fit and function. Refine tolerances, angles and geometry in hours or days rather than weeks.

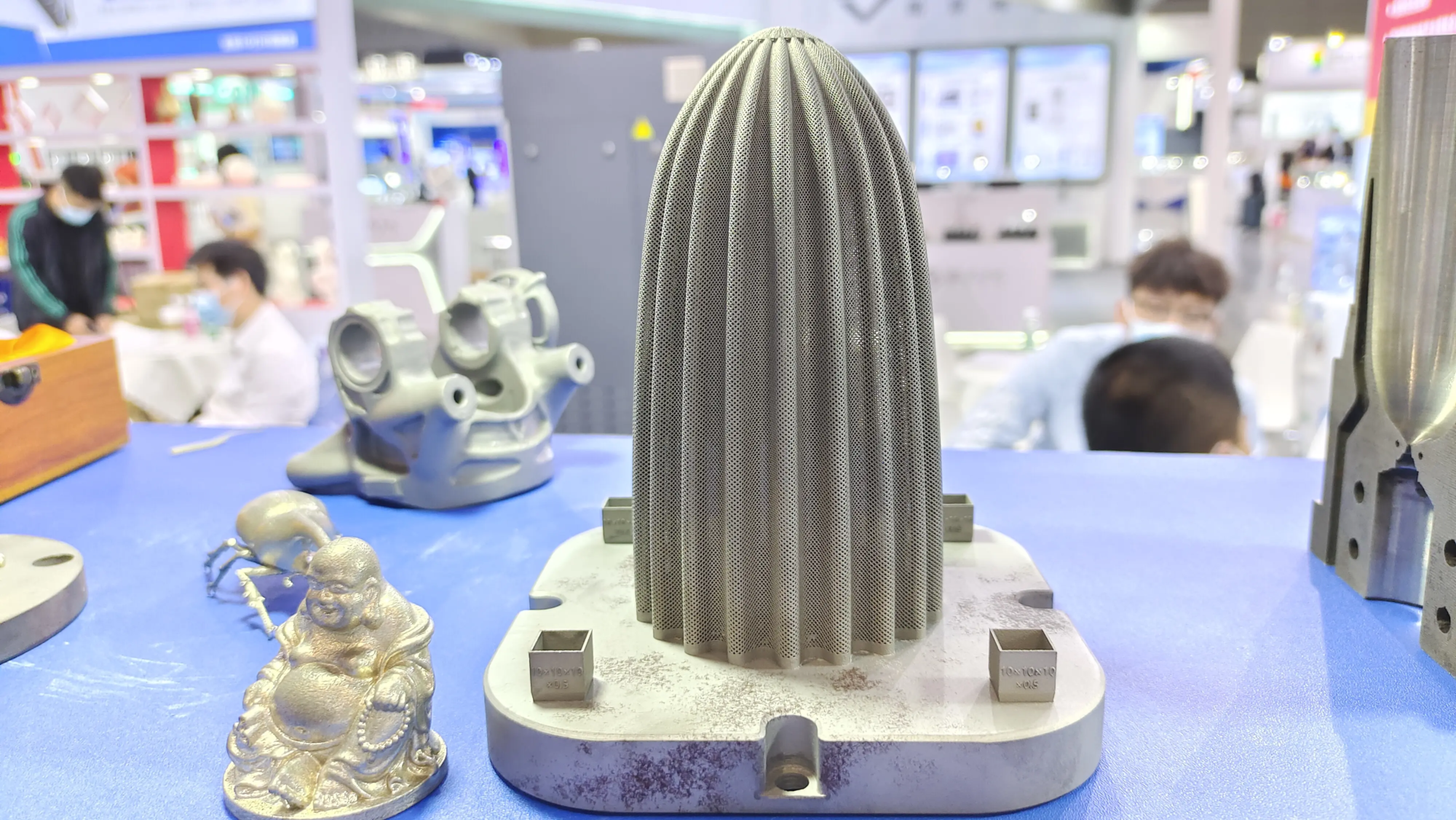

- Lightweight and optimized structure: Optimize the distribution of materials within the joint itself. Create lightweight but incredibly strong lattice or hollow core structure integrated with pentagons for use in aerospace or robotics technology.

- Multi-material potential (emerging): Some advanced 3D printing techniques allow for the embedding of different materials into a single print, which may produce self-lubricating joints, or combine rigid pins with a shocking tail.

- Low volume production and customization: Economically, there are no expensive tools that produce small quantities of parts. Ideal for custom mechanisms, fixtures, fixtures and limited edition products.

- Functional end-use parts: When paired with the correct material, print setup and post-processing, 3D printed metal dovetail joints enable excellent strength and durability for demanding applications.

Key considerations for success

Achieving a perfect 3D printed dovetail tail requires careful design and process knowledge:

- Tolerance is the king: The difference between seamless slides and clogged joints is 100%. Explain printer accuracy, material shrinkage, thermal expansion and surface texture. Digital prototyping and testing printing are crucial.

- Direction is important: The orientation of the joints on the construction plate can affect the strength and surface finish of the critical mating surface. Support for structural placement and disassembly requires careful planning to avoid damage to the functional surface.

- Geometric optimization: Avoid sharp corners in places where stress is concentrated. Implement rounded corners and needle forks appropriately. Make sure it is sufficient "neck" Thickness and participate in sufficient mating surfaces to obtain strength.

- Surface finish requirements: A sliding surface requires a specific level of roughness to operate smoothly. First aid status may be insufficient.

- Material selection: The function of the joint determines the material. Plastics (such as nylon, peep) can be used for lower loads. Metals (aluminum alloy, stainless steel, titanium) are required for high strength, wear resistance and thermal stability.

GRESTHERMENG: Your Precision Metal 3D Printed Dovetail Companion

Imagine designing complex internal dovetail mechanisms for high-load aerospace components or unique sport mounts requires perfect repeatability. Traditional creation accident; great prosperity.

At Greatlight, we specialize in the boundaries of rapid metal prototyping and production. Our Arsenal includes Advanced Selective Laser Melting (SLM) 3D Printerprecisely fuse fine metal powder with high energy laser. This technology is ideal for complex geometric shapes such as functional dovetail joints.

Why use it for metal dovetail joints?

- Cutting-edge SLM technology: Achieve complex high-resolution metal dovetails with excellent mechanical properties.

- Extensive material expertise: Handle a variety of high-performance metals: aluminum alloy (ALSI10MG, AL7075), stainless steel (316L, 17-4PH), titanium alloy (TI6AL4V), nickel alloy and tool steel. We guide you to get the best materials for strength, weight, corrosion resistance and heat requirements.

- Precision Engineering: We understand the key tolerances. Our expertise in process optimization ensures the dimensional accuracy required for a smooth fit, functional metal dovetail joint.

- One-stop solution: Apart from printing, our comprehensive Post-processing services are crucial for dovetail success:

- CNC machining: Achieve super-exquisite mating surfaces, tight tolerances and perfect flatness on key faces.

- Heat treatment: Improves material strength, reduces residual stress and improves durability.

- Shooting/bead explosion: Refine the surface texture for smoothing operations.

- Polishing/electropolishing: Create mirror-like finishes on the sliding surface to minimize friction.

- Surface coating: Use specialized coatings (such as DLC, PTFE, NI-PTFE) to resist wear or reduce friction.

- Speed and flexibility: From the initial concept to functional metal prototypes or low-volume production batches with dovetail joints, we deliver at an amazing rate – much faster than the traditional tool route.

Conclusion: The integration future is seamless

3D printed dovetail joints represent more than just manufacturing technology; they unlock new paradigms for structural design. The freedom to integrate strong, elegant and complex mechanical interlocks into various parts of a prototype or final product will accelerate innovation. Tolerance control and surface finish requirements are challenges in terms of expertise, but the solution is here.

For demanding applications that require precision, strength and versatility Metal dovetail jointit is crucial to work with experienced rapid prototyping providers. Our advanced SLM features, extensive material knowledge and comprehensive collation services ensure your interlocking design transitions from digital glory to perfectly functioning reality. We solve complex rapid metal prototyping problems every day, including mastering the art and science of 3D printing dovetails. Explore the potential of seamless, high-strength connections – Let us create the future together.

FAQ: 3D printed dovetail joints

Are 3D printed dovetail joints strong enough?

- answer: Absolutely, especially when 3D is printed in metal using SLM/DML and designed/processed correctly. Their power competitors and in specific complex designs can transcend traditional manufacturing. Substance selection, orientation, print quality and post-treatment (such as heat treatment) are critical to achieving maximum strength.

Can I print 3D plastic dovetail seam joints efficiently?

- answer: Yes, materials such as reinforced nylon (PA6, PA12 GF), PETG, PET-CF and PEEK are ideal for functional plastic dovetail joints in fixtures, fixtures, lighter working mechanisms and prototypes. Tolerance and friction characteristics require careful design considerations. Smooth sliding may require post-processing.

What tolerances can usually be achieved for 3D printed dovetails?

- answer: Typical SLM metal printing achieves dimensional tolerances of ±0.1 to ±0.2 mm (±0.004" To ±0.008"). With optimized design, calibration and post-treatment processing of critical mating surfaces, below ±0.05 mm (±0.002") Tolerances are achievable and are crucial for perfect sliding fit.

How do I design a dovetail joint for 3D printing?

- answer:

- Clear: Include calculated gaps (e.g., 0.15-0.25mm of metal) in the CAD model to allow tolerance and smooth assembly.

- Draft/angle: The classic dovetail angle is 1:6 to 1:8. Make sure that there is enough draft to prevent binding.

- Fillets/Chamfers: Add small rounded corners to the inner corners to reduce stress concentration.

- Surface finish: Specify which surfaces are critical mating surfaces that may require late or polishing.

- direction: Model joints consider printing directions to minimize support to critical surfaces and optimize layer adhesion strength.

- answer:

Why do I need to post-process the 3D printed dovetail?

- answer: Current parts have inherent surface roughness. In order for the dovetail tail to slide smoothly and work correctly, the mating surface usually requires machining, polishing or other decoration. Critical planar surfaces may require machining for parallelism and perpendicularity. Post-treatment can also enhance strength (heat treatment), corrosion resistance (paint) and wear resistance (paint/fire type).

- Which material is recommended for Greatlight to match with high strength metals?

- answer: Key choices include Aluminum alloy (ALSI10MG): Excellent strength to weight ratio. Stainless steel 316L: Extreme corrosion resistance and good strength. Maraging Steel (e.g., 1.2709): Excellent strength after heat treatment. Titanium (Ti6al4v): High-quality strength to weight and biocompatibility. Consult our engineers based on your specific application requirements.

Customize quick prototyping parts with advanced dovetail seam joints or any complex geometry with Greatlime. Experience seamless integration, excellent quality and competitive price – get a quote now!