Unleash your creativity: Use 3D printing to create a personalized gift card holder

Gift cards offer convenience, but they often lack the personal touch of a thoughtful gift. What if you could combine the flexibility of a gift card with a unique, handmade feel? 3D printing is a revolutionary technology that is changing the way we create personalized gifts. Forget the generic plastic sleeve; imagine handing over a gift card inside a miniature treasure chest, a stylish geometric sculpture, or a charm shaped like the recipient’s hobby. That’s the magic of a 3D printed gift card holder, which combines practicality with deep personalization.

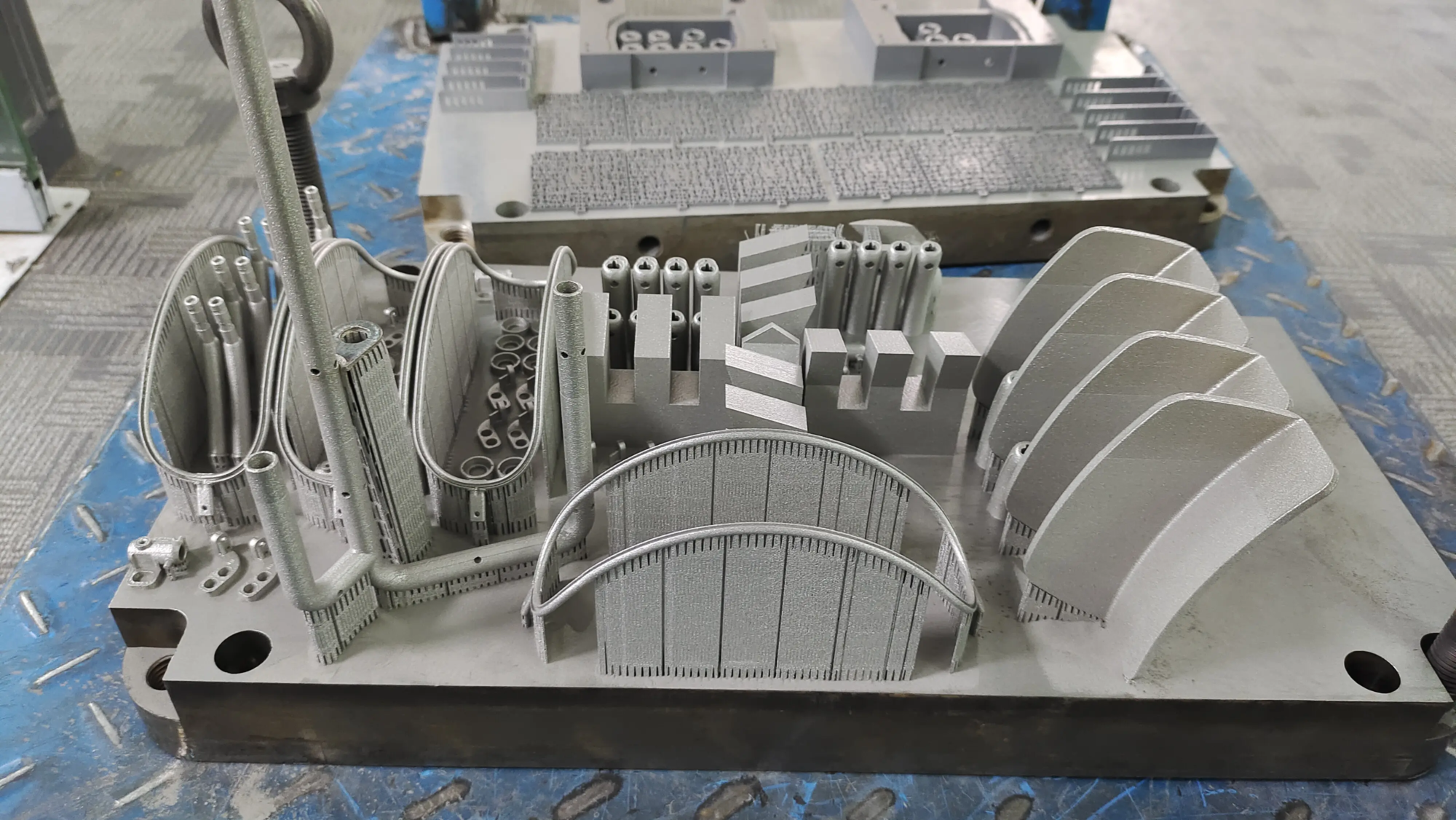

exist huge lightwe see firsthand how additive manufacturing can unleash unprecedented creativity. As a professional rapid prototyping manufacturer, we help individuals and businesses transform complex digital concepts into tangible, high-quality metal realities using advanced SLM (Selective Laser Melting) technology along with a full suite of post-processing services. While today’s focus is on the artistry of the gift card holder, the underlying principles – precision, material excellence and customization – are at the heart of our mission to expertly solve complex rapid prototyping challenges.

Why 3D printing dominates among gift card holders:

- Ultimate personalization: This is an outstanding advantage. Design the holder to reflect the recipient’s passion (a small guitar for the music lover, a bicycle for the cyclist), incorporate their name, or be customized to a specific holiday/theme (a spooky tombstone for Halloween, an elegant snowflake for Christmas). You are only limited by your imagination.

- Release complexity: Traditional manufacturing struggles with complex lattices, organic shapes or internal mechanisms. 3D printing can easily handle undercuts, hinged compartments or complex geometries, making the stand a functional work of art.

- Material Versatility Desire: From affordable and colorful glycolic PLA and stretchy PETG, to stylish and sturdy metals like stainless steel, titanium, and even precious metals through services like GreatLight, you can choose the perfect look and feel.

- Perfect fit and function: Design the holder to fit a specific card size, include slots for easy sliding, add a keychain hole or secure a magnetic clasp – create something that not only holds cards in place but also enhances the experience.

- Scalability and efficiency: Whether you need a truly unique piece or a small batch of corporate or wedding favors, 3D printing can efficiently handle low-volume production without the need for expensive tooling.

- Prototype perfection: Iterate on designs with ease. Print prototypes to test size, card insertion/ejection and overall feel, and refine the design digitally before going to final prints.

Make your work: from pixels to now

Creating a beautiful gift card holder involves a few key steps:

- Concept and design:

- Brainstorming: Consider the recipient, occasion, material (affects complexity and size) and key features (hinges? locks? brackets?).

- measure: Measure your gift card accurately. Tolerances are included (usually around 0.2-0.5 mm of extra space on each side) to allow for ease of insertion/removal and print size differences.

- software: Use 3D CAD software (Fusion 360, Tinkercad, SolidWorks, Blender) or find customizable designs on platforms like Thingiverse or Printables.

- Design principles:

- Wall thickness: Ensure sufficient thickness for strength (at least 1.5 mm for plastic, thicker for buckles or metal). GreatLight’s metal capabilities enable extremely strong thin walls designed specifically for the SLM process.

- Card reservation: design