Understand the True Cost of Markforged Metal 3D Printing: A Comprehensive Guide

Metal additive manufacturing (AM) continues to revolutionize prototyping and production. In this area, Markforged has carved out a unique niche with its proprietary technology Atomic Diffusion Additive Manufacturing (ADAM) technology. Markforged metal printers are known for their user-friendliness and accuracy, providing easy-to-use metal solutions. However, understanding Total Cost of Ownership (TCO) Crucial before investing.

This guide breaks down the cost structure of Markforged Metal 3D printing:

1. Is the bubble too big? initial capital investment

- Printer purchase price: This is the most obvious cost. Current Markforged metal systems, such as the Metal X Series, start at $100,000 to over $200,000, largely driven by model capabilities, build volume (larger chambers cost more) and automation capabilities.

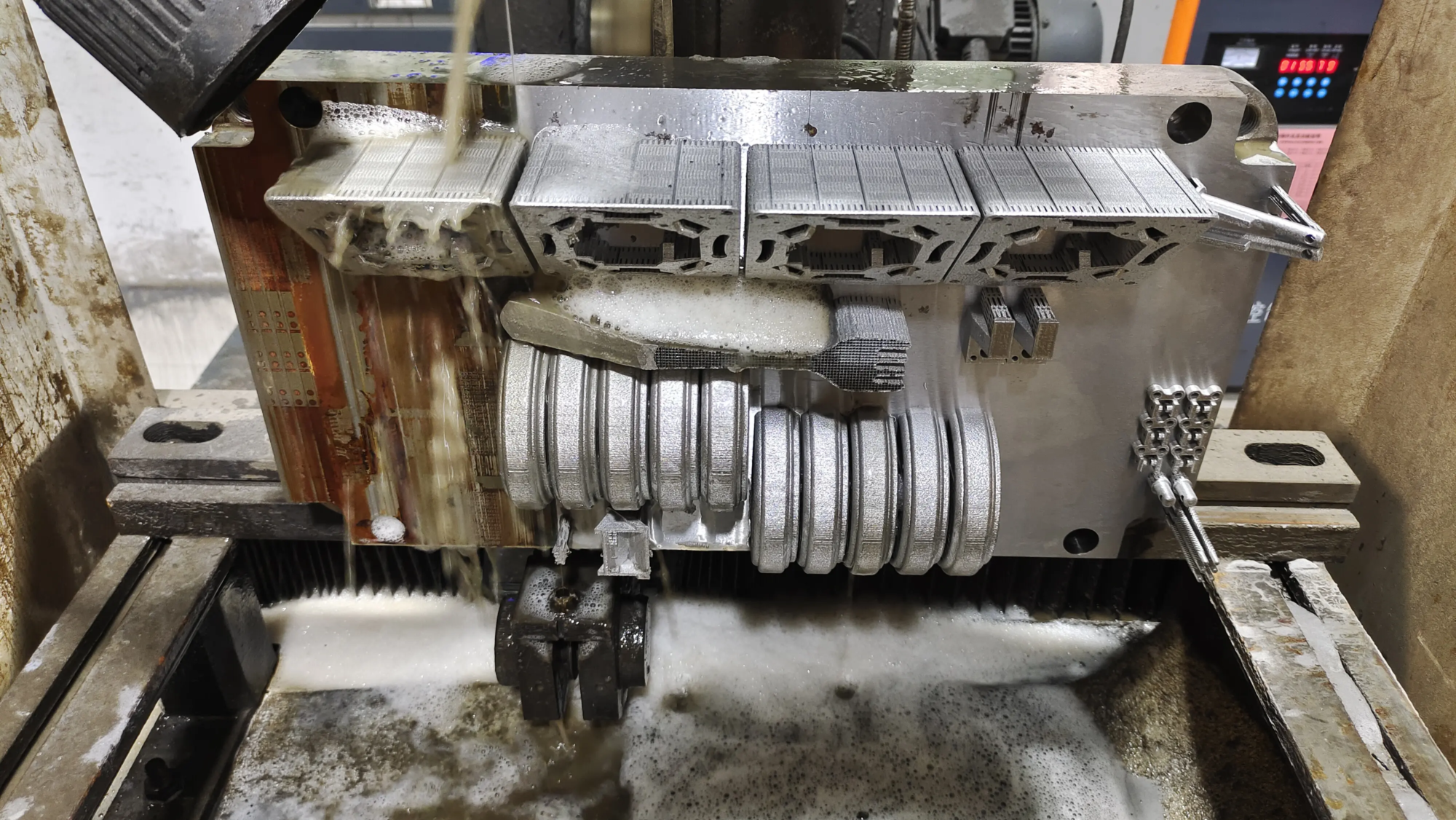

- Degreasing and sintering furnace: Unlike powder bed fusion systems, Markforged’s process separates printing (done using metal powder in a plastic binder) from sintering. The necessary debinding and sintering furnaces are significant additional capital expenditures, often costing tens of thousands of dollars each. Take these factors into consideration right away.

- Facility preparation: Ensure adequate power, ventilation (especially for sintering), compressed air, stable flooring/wiring, and possible HVAC modifications. Don’t underestimate installation/service costs.

2. Beyond the Machine: Operating Expenses (OpEx)

- Metal powder: Markforged The abbreviation details for metal powders (such as stainless steel, tool steel, copper, inconel) determine the material selection. Costs vary:

- 17-4 PH effective Stainless Steel: ~$250-$400/kg

- D2 tool steel: ~$700-$900/kg

- Copper: Prices fluctuate; generally higher.

- NOTE: Powder cost/ROI depends on powder recovery efficiency and part packing density. Lower utilization = higher cost per part.

- Material box: Metal powder ink cartridges for printers also incur costs.

- Build the board: This will increase the input price of the stl file. All printers require periodic replacement.

- Consumables: Includes blasting media, hob/holder for sintering, inert gases (e.g. argon for sintering), solvents/solutions for cleaning/degreasing stages and lubricating oils.

- Maintenance and service contracts: Annual maintenance contracts are critical to minimizing downtime, but add cost (around 5-15% of the printer cost per year). Consider potential repairs.

- Personnel costs: Skilled operators with expertise in safe powder handling, sintering programming, and post-processing are required.

- Utilities: Electricity consumption (printers, furnaces) and compressed air are significant expenses.

3. Hidden costs: post-processing and efficiency

- Degreasing time: Parts typically need to be soaked in a solvent bath for about 1-3 days to remove the adhesive before being sintered.

- Sintering cycle time: Sintering depends on furnace type/material/material load – may last longer than 24 hours.

- Post-sintering process: Parts require sandblasting/laser engraving for marking/traceability/resurfacing. Complex geometries may require mechanical/laser cutting processes to remove supports. Dimensional accuracy and actual functional requirements impact finishing labor* costs.

- Scrap/Waste: Failed prints and poorly recycled powder result in wasted material and increase the effective cost per part.

- Downtime and learning curve: Printer/database troubleshooting, your team’s optimization parameters directly impact productivity.

Compare Markforged TCO to alternatives:

- Comparison with powder bed fusion (SLM/DMLS): Markforged systems generally have lower upfront cost/operational complexity than comparable high-end powder bed machines (approximately $400,000 to over $1 million). But due to differences in shrinkage rule accuracy, the mechanical properties/dimensional accuracy of sintered parts may be slightly lower unless compensated by calibration skills/laser scanning QC chains.

- Compared with traditional processing: Great for complex geometries/custom geometries, replacing roughing operations, but less economical for simple/high volume production. *

- With outsourcing: Hybrid approach maximizes efficiency: Outsourcing customized one-off/prototype testing cycles minimizes costs until the ROI is reasonable.

The GreatLight Method: Your Cost-Effective Metal Additive Manufacturing Partner

While there are advantages to owning a Markforged printer, the substantial capital investment and operational complexity has led many innovators (from startups to established OEMs) to partner with professional services organizations, such as Glow China.

- Eliminate capital expenditures: Avoid approximately $150,000 to $300,000+ printer and furnace investment/service fees/large cash reserve requirements.

- Optimize material usage: Leveraging our high utilization (from multiple printers running simultaneously), effective part cost/material loss can be reduced due to expertise in controlling sintering shrinkage/warpage/degreasing processes.

- Expertise on demand: Benefit from engineers optimizing support design/laser post-processing/furnace scheduling to maximize performance and ensure dimensional tolerance fidelity meets NPI requirements.

- Seamless post-processing: One stop solution including heat treating/anodizing/polishing/machining/enameling/permanently printed embossing – saving weeks/managing inconsistencies across multiple suppliers.

- Speed and scalability: Scalable building output extensions to quickly bypass internal delivery times/training delays.

- Material flexibility: Not only metal but also resin/PEEK/HCP locking pairs can be used allowing the entire development/prototyping/low volume manufacturing to take place under one roof.

Conclusion: Make an informed choice

A fully equipped facility like Great(br/>Light exemplifies responsive manufacturing at a competitive price point. If there are demand fluctuations or capital bottlenecks are an obstacle, outsourcing metal printing makes strategic sense both economically and operationally.

Whether investing directly or leveraging a partner, make sure the TCO includes hidden costs (materials/debinding/sinter cycles/wages). Evaluate part suitability relative to sinter density/mechanical needs with functional prototypes to determine which metal process is best suited!

Weiguang team, 2024 — Refine your project designs at competitive prices, anytime.

FAQ: Markforged Metal 3D Printer Cost

Q1: How much does the MARKFORGED METAL X printer cost?

one: The range that goes into a Markforged metal printing system is typically approx. USD 100,000-USD 200,000+ USD Exclusive tax/shipping rates for printer/degreaser/sinter furnace combinations. The larger MetalX 20″ size increases pricing substantially.

Q2: What affects the price paradigm of metal 3D printing?

- Metal powder ballistic leakage loss/process waste/difficulty in recovery rate.

- Support structure area/tiny channels detergency effectiveness also impacts machine yield.

- Sintering furnace size/power consumption cycle/degreasing solvent method/etc. Security system operating expenses keep rising!

- Fractional engineer time is allocated to CAD pre-processing for wear simulation simulations.

Q3: Why entrust metal prototyping/production to a service agency?

Enterprises choose outsourcing points:

- Internal infrastructure availability shortcomings[CNC-EM/Vacuum Furnaces] Becoming expensive to license/operate.

- Increased initial pressure to require extensive training leads to a seamless outsourcing bridge,

- Enable faster turnaround, skip accumulation of internal queue limits,

- Reduce cost per part by facilitating consolidated powder/material purchases through local resource pooling/utilization.

Question 4: What material compatibility are there when using GreatLight Markforged type services?

We usually print using the following methods:

Stainless steel (17-4PH, 316L), tool steel (H13/CMV tool steel/M2), Inconel 625, copper Gr1, tungsten (tungsten carbide mixture) and special alloys that meet engineering requirements!

Q5: How much money can you typically save by outsourcing metal printing?

Cost savings are primarily determined by output patterns/design complexity/competitor prices/production trial margin improvement statistics, benchmarked against maximizing economics against unstructured AM ownership prerequisites.

Reach out your hand glow rapid prototyping Discuss Exclusive Today!