Combining mass manufacturing with speed: How Massivit 3D is changing the game

For decades, rapid prototyping and manufacturing were often limited by the physics of traditional methods. Creating large prototypes, molds, tooling or end-use parts means complex logistics, extended lead times and significant costs. Additive manufacturing promised a solution, but scaling 3D printing to truly large sizes without sacrificing speed or surface quality proved to be a major obstacle. This is where Massivit 3D comes in, not only extending existing technology but fundamentally rethinking the speed at which large objects can be additively manufactured.

GreatLight is a specialist rapid prototyping manufacturer at the forefront of advanced technologies such as SLM metal printing, and we are constantly evaluating innovations that push the boundaries. Massivit 3D printers represent one of the most compelling advancements in significantly accelerating the production of large parts, complementing our existing metal and plastic printing capabilities.

Core Innovation: Gel Dispensing Printing (GDP™)

The magic of Massivit 3D is its proprietary Gel Dispensing Printing (GDP™) technology. Forget the slow, layer-by-layer sintering or extrusion methods common in large-format FDM. GDP™ utilizes two core components:

- Photopolymer gel material: A specially formulated UV-curable gel that retains its shape immediately after deposition.

- High-speed deposition and curing: Precision printheads extrude thick beads of gel at breakneck speeds. Crucially, as the gel exits the print head, it passes through an intense array of UV light that instantly cures the outer surface. This creates a self-supporting "shell" While the inside remains slimy.

The result? The printer can extrude thick, voluminous "Wire" Materials can be processed at high speeds without the need for traditional support structures. This makes building very fast, especially for large, curved or geometrically complex shapes where traditional methods are slow.

Breaking the Massivit Advantage: Why It’s Revolutionary

Massivit’s impact comes from overcoming key limitations:

- Unparalleled speed: This is a feature of the headlines. Massivit printers are much faster than traditional large-format 3D printing. Projects that take several days or weeks can usually be Hour. For prototypes, molds, props and tooling, this can compress design cycles and speed time to market.

- Really large build volume: Machines such as the Massivit 5000 offer build enclosures with heights and widths exceeding 1.5 meters, enabling the creation of large single-piece parts that previously required complex assembly.

- Untethered by supporting structures: The self-supporting nature of GDP™ eliminates the time-consuming process of designing, printing and removing supports. This simplifies the workflow, reduces material waste, and maintains the surface quality of the final geometry.

- Material Versatility and Properties: Massivit materials, such as the Dimengel range, offer a range of properties tailored to different applications: tough, rigid, impact-resistant, transparent, flame-retardant and even castable. This opens doors for different industries.

- Cost-Effectiveness of Scale: For large parts, Massivit significantly reduces the overall cost per part by reducing machine time, labor (reduced post-processing), material waste (no supports), and minimizes assembly requirements. Machining costs for molds and models have also dropped significantly.

Where Massivit shines: diverse applications

This combination of speed, scale, and versatility unlocks applications that were previously impractical or prohibitively expensive:

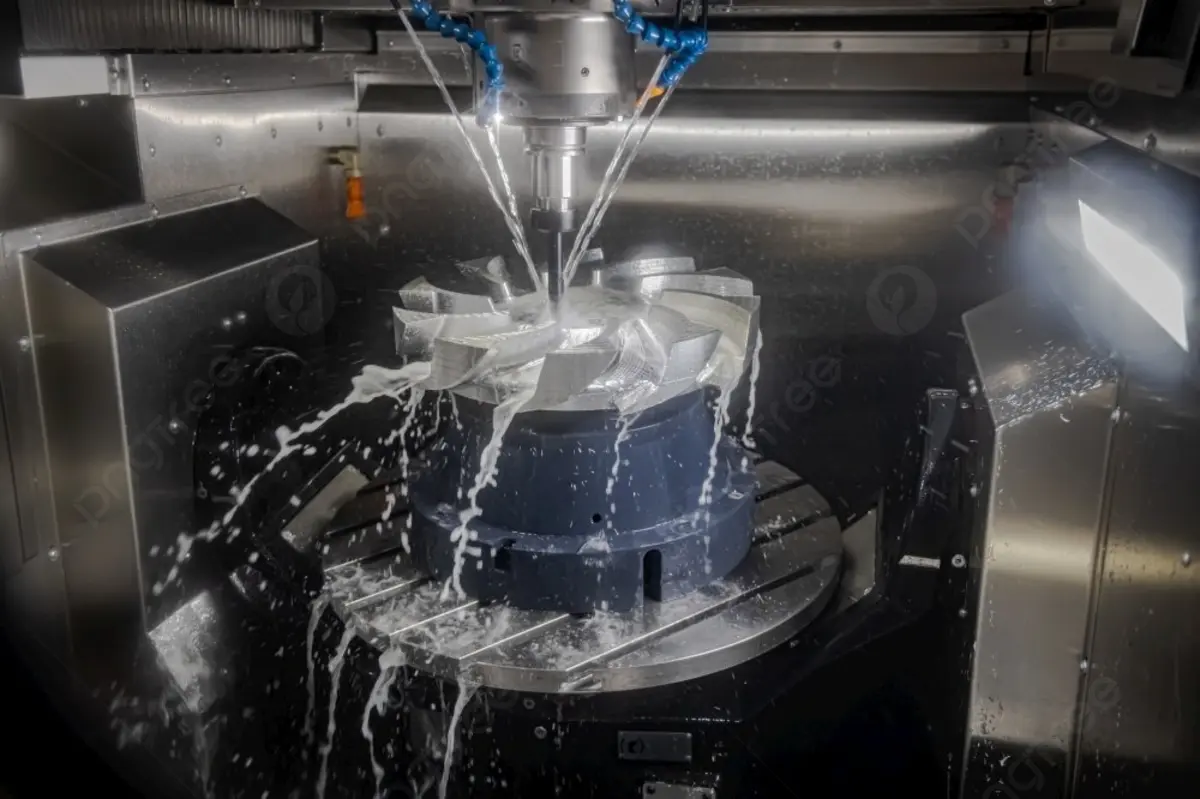

- car: Rapid prototyping of full-size vehicle parts (bumpers, dashboards, panels), jigs, fixtures, end-of-arm tooling (EOAT) and custom molds.

- aerospace: Lightweight molds for composite parts, molds and large nacelle components. Faster iteration of wind tunnel test models.

- ocean: Large molds for hull parts, interior prototypes, custom fixtures and even decorative elements.

- Entertainment and theme parks: Produce towering set elements, lifelike props, characters, themed structures and animated frames faster than ever before.

- Point of Purchase (POP) and Retail: Eye-catching, oversized retail displays, signage and custom fixtures are delivered faster than ever.

- Casting and Casting: Produce large quantities of high-precision models and cores directly from metal casting CAD data.

- put up: Architectural models, complex molds for decorative concrete elements and large-scale design verification.

Integration of modern manufacturing

Massivit printers are not stand-alone magic boxes. They thrive when integrated into digital workflows. CAD data drives the process, requiring optimized slicing software, such as Massivit’s dedicated slicers, to efficiently convert complex geometries into efficient GDP™ toolpaths. Post-processing requirements depend on the application – usually minimal sanding or painting, sometimes machining to obtain critical dimensions, or direct casting. For ultimate precision machining or molding compatibility, parts can serve as masters for secondary operations such as silicone molding. This highlights why it is crucial to work with a service provider experienced in the entire manufacturing chain, including advanced post-processing.

Conclusion: Scaling ambitions achieved

Massivit 3D disrupts the status quo in large part manufacturing and prototyping. Its GDP™ technology provides a compelling solution where speed, size and independence from supporting structures are critical. By drastically reducing the time and costs associated with producing large molds, models, prototypes, scene elements and tooling, Massivit enables industries to iterate faster, produce more cost-effectively and bring ambitious designs to reality without compromise.

At GreatLight, while our core expertise lies in delivering exceptional metal parts through advanced SLM 3D printing and comprehensive post-processing, we recognize the transformative power of complementary technologies like Massivit 3D. We actively monitor such innovations to determine best Technology tailored to our customers’ specific rapid prototyping challenges. Whether your project requires the strength and precision of metal, the speed and scale of polymer gel deposition, expert finishing or a combination of both, our goal is to be a trusted one-stop partner in the rapidly evolving world of manufacturing. When large-scale, high-speed additive manufacturing provides the ideal solution, Massivit 3D will undoubtedly revolutionize what is possible.

FAQ: Understanding Massivit 3D Printing

Question 1: What types of objects are Massivit printers best suited for?

A1: Massivit excels at handling large (usually human-scale or larger), complex-shaped monolithic objects where speed is critical. Ideal applications include molds, models, rapid prototypes (especially exterior models), tooling (jigs, fixtures, EOAT), theatrical/scenic elements, signage/retail displays and architectural components. It is not well suited for finely detailed miniatures or high-strength functional end-use parts that require metal-like properties.

Question 2: How strong are Massivit printed parts?

A2: Strength varies greatly depending on the specific Dimengel material selected. They offer a wide range of materials, from very strong and durable resins suitable for impact-resistant tools to tougher resins for functional prototyping. While they are impressive and suitable for many industrial applications, they often cannot match the strength, heat resistance or durability of the hardened metals or engineering thermoplastics used in end-use production parts. They are ideal for molds, models and non-load bearing prototypes/parts.

Q3: Is post-processing difficult?

A3: GDP™ produces near-net-shape parts and eliminates traditional support removal challenges. However, some post-processing is usually required. This may involve removing the internal support gel (washing it off with water/air), light sanding to smooth out ply lines (not as noticeable as FDM, but present), painting or sealing. For mold or forming applications, surface machining may be required to meet ultra-precision mating surface or casting requirements. Overall, at this scale, post-processing is often simpler and faster than fused deposition modeling (FDM).

Q4: How expensive is Massivit printing?

A4: A: While printers represent a significant capital investment, the highlight of the technology is operating cost efficiency For large parts. High speed greatly reduces machine time costs. Eliminating support structures minimizes material waste. The ability to quickly and reliably manufacture large, robust parts often means a lower overall cost per part compared to CNC machining, traditional large-scale FDM printing, hand fabrication, or outsourced production, especially when factoring in significantly reduced lead times.

Q5: Can Massivit prints be used as molds?

A5: Yes, this is one of its most powerful applications. Materials such as Dimengel 40-60 (Mold Epoxy for Additive Manufacturing) are specifically designed to be used directly as molds for composites (carbon fiber, fiberglass), concrete, PU castings and even short-term thermoforming. Its rapid production means mold making time is reduced from weeks to hours.

Q6: How does Massivit compare to other large format 3D printers?

A6: The key difference is Speed and scalability. Massivit GDP™ technology fundamentally bypasses the layer-by-layer speed limitations inherent in technologies such as pellet extrusion (large FFF/FDM), powder systems (SLS/SLM for polymers/metals) or resin vats. For large volume fills (such as thick sections), GDP™ deposits materials orders of magnitude faster while maintaining dimensional stability through transient surface solidification. It generally outperforms FDM in terms of surface finish that can be achieved on large surfaces without extensive post-processing.