Memorable shades, tangible results: Understanding memory color in 3D printing

In the world of product design and prototyping, aesthetics are often as important as functionality. Do you often reject product designs because of color perception? "leave," Even if the shape is perfect? This gut reaction taps into a powerful psychological concept memory color. As prototyping evolves, integrating this understanding directly into the 3D printing process is becoming a game changer. At GreatLight, leveraging advanced manufacturing technologies to meet complex requirements such as true color reproduction is at the core of our rapid prototyping services.

What exactly is memory color?

Memory colors are specific colors that our brains associate with familiar objects based on past experiences. Think of the bright yellow of a banana, the deep red of a fire truck, the special blue of a sunny sky, or the soft green of fresh grass. These are not just arbitrary colors; our minds encode them as "Correct." When a prototype deviates significantly from these ingrained expectations—replacing the banana model with a dull, muddy yellow—a subconscious dissonance is created. Even if the physical form is perfect, this feeling of being “wrong” can negatively impact user feedback, ergonomic evaluations, and market feasibility testing.

Beyond Plastic: Memory Color Meets Advanced Metal 3D Printing (and Finishing)

Traditionally, achieving high-fidelity color, especially memory color accuracy, has been primarily the domain of polymer 3D printing technologies, such as material jetting (e.g. PolyJet) or binder jetting using penetrating dyes. These systems deposit colored materials or adhesives layer by layer to build objects with millions of potential color combinations. Achieving accuracy in memorizing colors during these processes requires:

- Advanced color management: Use a spectrophotometer for precise calibration to accurately map digital color profiles (such as CMYK, sRGB, Pantone) to printed materials.

- High resolution printing: Ensure fine details and smooth color gradients to avoid streaks and produce realistic textures.

- Material consistency: Using photopolymer resins or powders, vibrant colors can be reproduced reliably and consistently across batches.

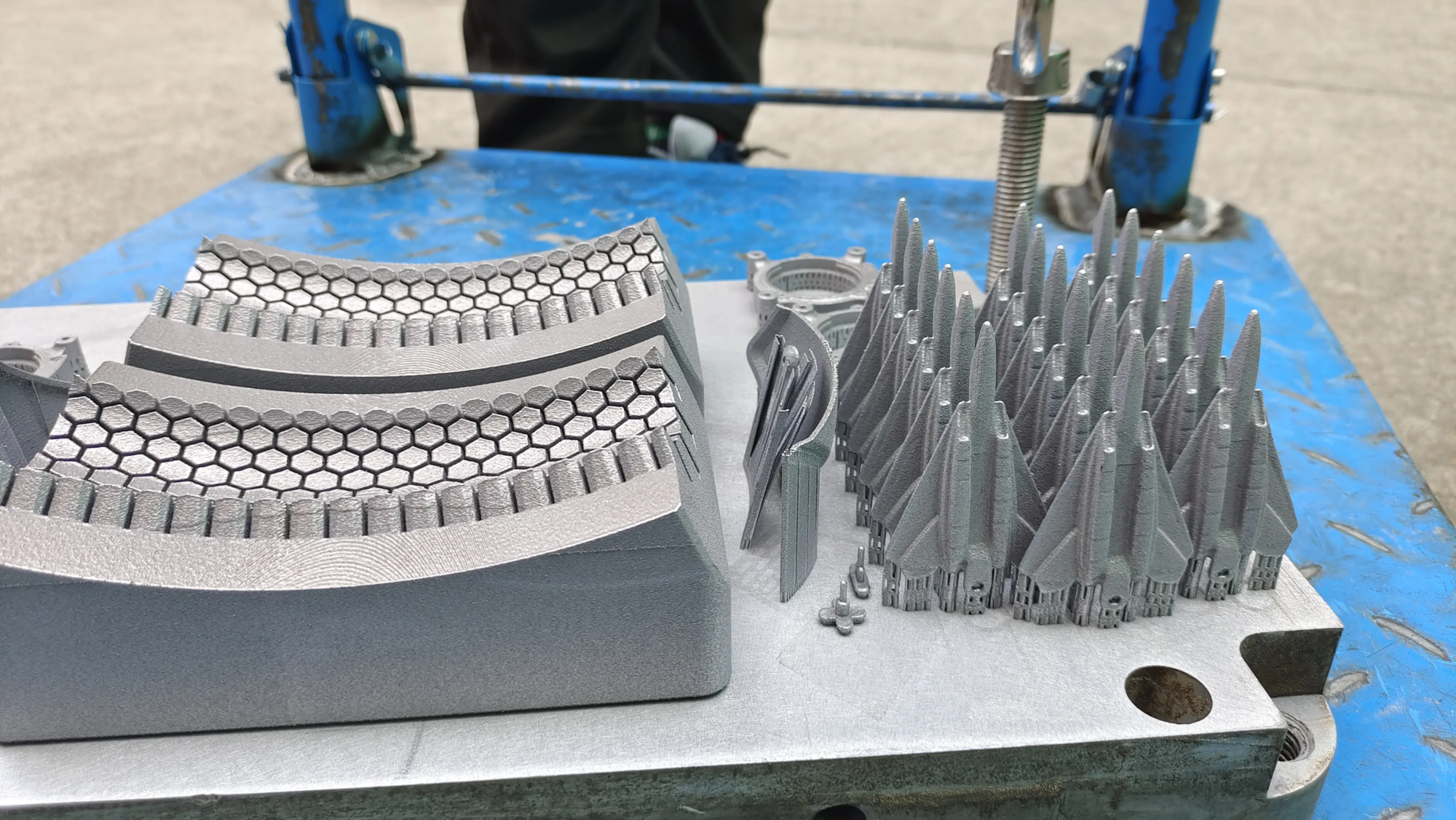

While GreatLight focuses on powerful Selective Laser Melting (SLM) Our commitment to metal 3D printing – essentially producing metallic gray parts – extends to delivering prototypes that fully meet our customers’ needs, Includes color accuracy. This is our extensive One-stop post-processing and finishing services become crucial.

For metal prototypes that require memorized color fidelity, we use sophisticated techniques:

- Precision painting and coating: Utilize state-of-the-art spray systems and skilled craftsmen to carefully apply paint that is an exact match to a Pantone or custom color swatch. Multiple layers, primers and varnishes ensure durability and the desired finish (gloss, matte, satin).

- Controlling anodizing: Mainly used for aluminum parts. While traditionally available in shades such as clear, black or gold, advanced color anodizing allows for a wider but more limited color palette than paint. Color perception is affected by the thickness of the underlying metal and oxide layers.

- Custom Staining/Surface Treatment: Special dyes or surface treatments suitable for certain metal alloys or secondary coatings.

- Color matching expertise: Our team has the knowledge and tools to analyze the target color and achieve a match that meets the remembered color expectations under specified lighting conditions (critical for color perception).

Why is memorizing colors important for your prototypes?

- Accurate user reviews: Archetypes are more than just physical representations; they elicit emotional and psychological responses. The right colors ensure that users interact with and perceive the prototype the same way they perceive the final product. Surgeon’s tool handles must be the correct blue/green for sterile association; consumer electronics must feel premium and familiar with precise white, black or metallic colors.

- Design verification and communication: During internal reviews or client presentations, accurate color can prevent misunderstandings about material selection, brand intent, or aesthetic direction. Stakeholders immediately buy in and fully evaluate the design.

- Market research success: Focus groups reacting to prototypes that lack true colors may provide misleading feedback based solely on reality "leave" The feel of the product undermines valuable research efforts.

- Reduce time to market: Identifying and correcting color differences early in the prototyping stage can avoid costly changes to tooling or production materials later on.

Industries utilizing memory color prototyping

From ergonomics to aesthetics