ISO 9001 Factory

ISO 9001 Factory

![]() Click here to upload or drag and drop your model to the canvas.

Click here to upload or drag and drop your model to the canvas.

The model is too large and has been resized to fit in the printer's build tray. [Hide]

The model is too large to fit in the printer's build tray. [Hide]

The model is too large, a fitting printer is selected. [Hide]

The model is too small and has been upscaled. [Hide]

Warning: The selected printer can not print in full color [Hide]

Warning: obj models with multiple meshes are not yet supported [Hide]

Warning: Unsupported DXF entity [Hide]

Warning: could not arrange models [Hide]

Model Stats:

| Material Volume: |

|

| Support Material Volume: |

|

| Box Volume: | cm3 |

| Surface Area: | cm2 |

| Model Weight: |

|

| Model Dimensions: |

x x

cm

|

| Number of Polygons: | |

| Number of Shapes: | |

| Total Path: |

|

| Print Time (hh:mm:ss): |

|

Unit Price:

Great Light offers 3D Printing and low volume manufacturing. We’ve boiled our innovation process down to four simple steps that work.

Upload your part to see if it’s eligible.

Faster, easier, higher quality on-demand manufacturing of metal parts

Features:

Austenitic stainless steel, with high strength and corrosion resistance, can be reduced to low temperature in a wide temperature range. The overall performance of this steel is better than 310 and 304 stainless steel. 316L stainless steel also has good resistance to chloride corrosion.

Application areas:

Auto parts, household appliances, electromechanical equipment

| Molding Process And Status | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation After Fracture (%) | Hardness (HBC) |

|---|---|---|---|---|

| Printing Performance | ≥560MPa | ≥480MPa | ≥30% | ≥90HV |

| Heat Treated Properties | ≥530MPa | ≥380MPa | ≥32% | ≥230HV |

Features:

A typical casting alloy with good casting properties, used for printing thin walls and complex geometric designs. This alloy contains silicon/magnesium, which significantly enhances strength and hardness, while also having good dynamic properties.

Application areas:

Auto parts, household appliances, electromechanical equipment

| Molding Process And Status | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation After Fracture (%) | Hardness (HBC) |

|---|---|---|---|---|

| Printing Performance | ≥290MPa | ≥200MPa | ≥5% | ≥65±5HBW |

| Heat Treated Properties | ≥430MPa | ≥260MPa | ≥3% | ≥120±5HBW |

Features:

It has the advantages of reducing molding cycle, improving product quality, and making the mold temperature field more uniform. It can print the front and rear cores, inserts, sliders, guide pillars and hot runner water jackets of injection molds.

Application areas:

Mould, Automobile

| Molding Process And Status | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation After Fracture (%) | Hardness (HBC) |

|---|---|---|---|---|

| Printing Performance | ≥950MPa | ≥900MPa | ≥5% | ≥32HRC |

| Heat Treated Properties | ≥1090MPa | ≥1000MPa | ≥10% | ≥48HRC |

Features:

This famous light alloy is characterized by good mechanical properties, strong corrosion resistance, low weight and good biocompatibility. It is the most widely used material for many engineering parts and biomedical implants.

Application areas:

1. Lightweight structures and parts (such as structural parts and aircraft engine parts used in the aerospace field, automotive parts, etc.).

2. Biomedical implants (such as bone plates, trabeculae, porous structures and other orthopedic implants).

| Molding Process And Status | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation After Fracture (%) | Hardness (HBC) |

|---|---|---|---|---|

| Printing Performance | ≥900MPa | ≥800MPa | ≥2% | ≥200HBC |

| Heat Treated Properties | ≥1000MPa | ≥900MPa | ≥4% | ≥294HBC |

Features:

It has high tensile strength, fatigue strength, creep strength and fracture strength at 700℃; high oxidation resistance at 1000℃; stable chemical properties at low temperatures; and good welding performance.

Application areas:

Steam turbines, liquid fuel rockets, cryogenic engineering, acidic environments, nuclear engineering.

| Molding Process And Status | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation After Fracture (%) | Hardness (HBC) |

|---|---|---|---|---|

| Printing Performance | ≥900MPa | ≥650MPa | ≥10% | ≥253HBC |

| Heat Treated Properties | ≥980MPa | ≥700MPa | ≥12% | ≥283HBC |

Features:

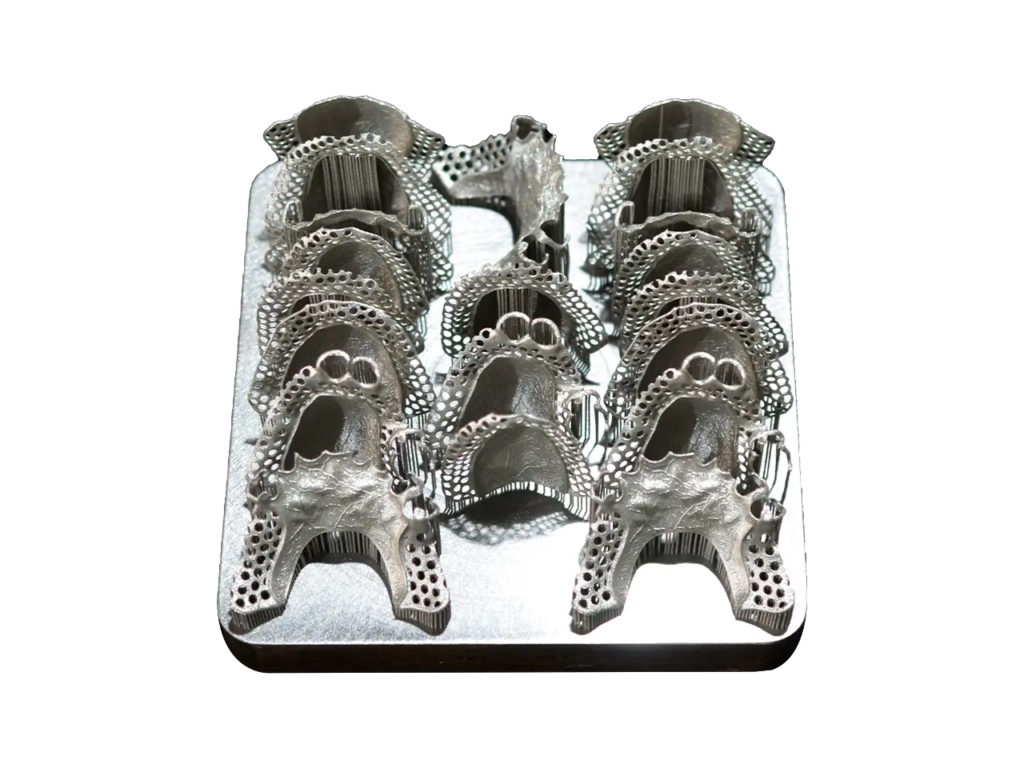

Cobalt-chromium alloy refers to a high-temperature alloy with cobalt and chromium as the main components. It has excellent corrosion resistance and mechanical properties. The parts made of it are high-strength, high-temperature resistant, and have outstanding biocompatibility.

Application areas:

Medical field (such as orthopedic implants, dental crowns, stents, etc.).

| Molding Process And Status | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation After Fracture (%) | Hardness (HBC) |

|---|---|---|---|---|

| Printing Performance | ≥900MPa | ≥750MPa | ≥5% | ≥228HBC |

| Heat Treated Properties | ≥1000MPa | ≥900MPa | ≥10% | ≥328HBC |

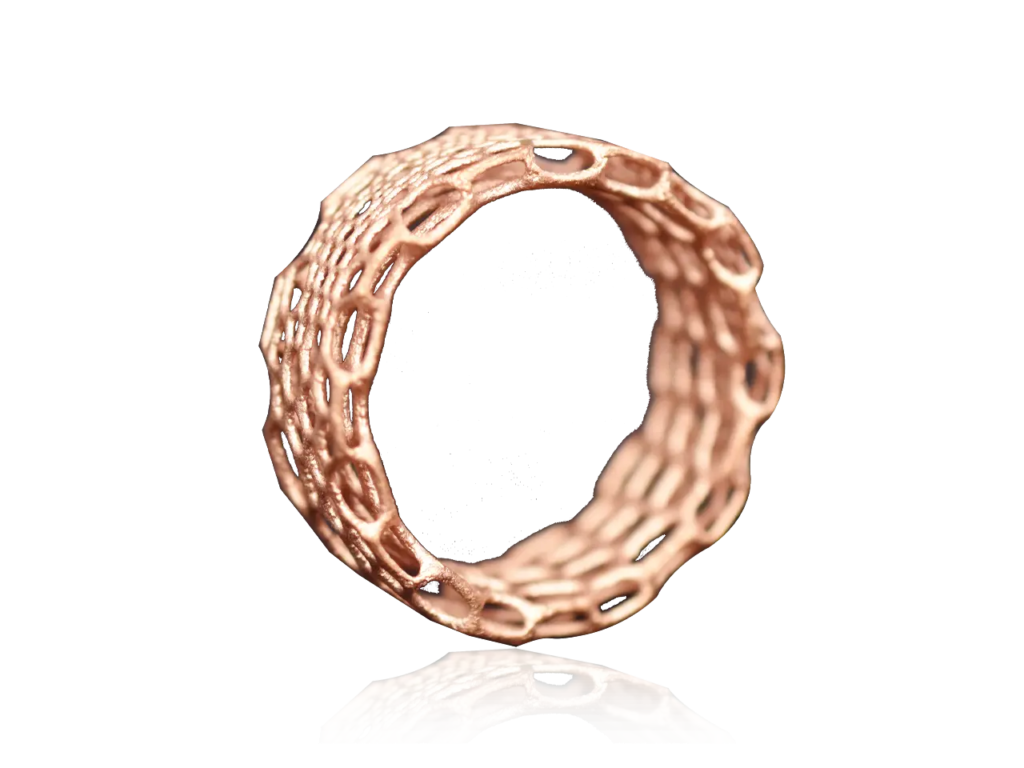

Features:

Bronze with tin as the main alloying element. The tin content is generally between 3% and 14%, and it is mainly used to make elastic components and wear-resistant parts.

Application areas:

Electrical wires, engine coils, printed circuits, roofing materials, plumbing materials, heating materials, jewelry, etc.

| Molding Process And Status | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation After Fracture (%) | Hardness (HBC) |

|---|---|---|---|---|

| Printing Performance | ≥150MPa | ≥90MPa | ≥2% | ≥34HBC |

| Heat Treated Properties | ≥230MPa | ≥130MPa | ≥5% | ≥48HBC |

Features:

Chromium bronze is a copper alloy containing 0.4% to 1.1% Cr. Chromium bronze is widely used in high-temperature conductive and wear-resistant parts of electrical equipment.

Application areas:

Motor commutators, collector rings, high temperature switches, welding machine electrodes, rollers, clamps, brake discs and discs used in bimetallic form, and other parts requiring high thermal conductivity, electrical conductivity, and high thermal strength.

| Molding Process And Status | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation After Fracture (%) | Hardness (HBC) |

|---|---|---|---|---|

| Printing Performance | ≥240MPa | ≥90MPa | ≥2% | ≥34HBC |

| Heat Treated Properties | ≥300MPa | ≥160MPa | ≥5% | ≥48HBC |