Create your own legendary MF DOOM mask: a comprehensive 3D printing guide

For hip-hop fans and producers alike, few symbols are as instantly recognizable and shrouded in mystery as MF DOOM’s iconic metal mask. Inspired by Marvel’s Doctor Doom, the complex piece is inseparable from the late rapper’s character. Thanks to 3D printing technology, enthusiasts can now recreate this iconic artifact, but it requires careful execution. This guide will guide you through every step from digital file to finished product, leveraging expert insights for superior results.

The charm and challenges of MF DOOM masks

Unlike simple props, DOOM masks have symbolic meaning. Its smooth metallic curves, sharp angles and intricate details demand precision. The plastic print captures the form, while the metal captures the essence—cold, heavy, and imposing. Whether you choose PLA for cosplay or venture into metal for authenticity, understanding the intricate crafting process is crucial.

Step by Step: Print DOOM Masks Like a Pro

1. Protect the security of STL files

Finding the right base model is crucial:

- Numerous DOOM mask models are available from platforms such as Cults3D, Thingiverse or MyMiniFactory – give priority to detailed versions with precise facial plate angles and back head mechanism.

- Evaluate comments: Check for comments about successful printing, required support structures, and assembly requirements. Some designs are one-piece; others are multi-part assemblies.

- Zoom: measure your head! Scale the STL in slicer software such as Cura or PrusaSlicer to ensure a snug fit. Note the end clearance of the internal dimensions.

2. Printer and Material Selection: Plastics vs. Other Materials

- PLA/PETG (desktop FDM): Easy to use and cost effective for beginners. Use PLA+ or PETG for better layer adhesion and durability.

- Advantages: easy printing, wide color selection, light weight.

- Cons: Lacks weight and metallic authenticity. Extensive post-processing is required to imitate metal.

- Resin (SLA/DLP): Excellent capture of fine details.

- Advantages: Near-perfect reproduction of complex surfaces. Great for complex designs.

- Disadvantages: Brittle compared to filament/FDM; requires careful handling and thorough post-curing.

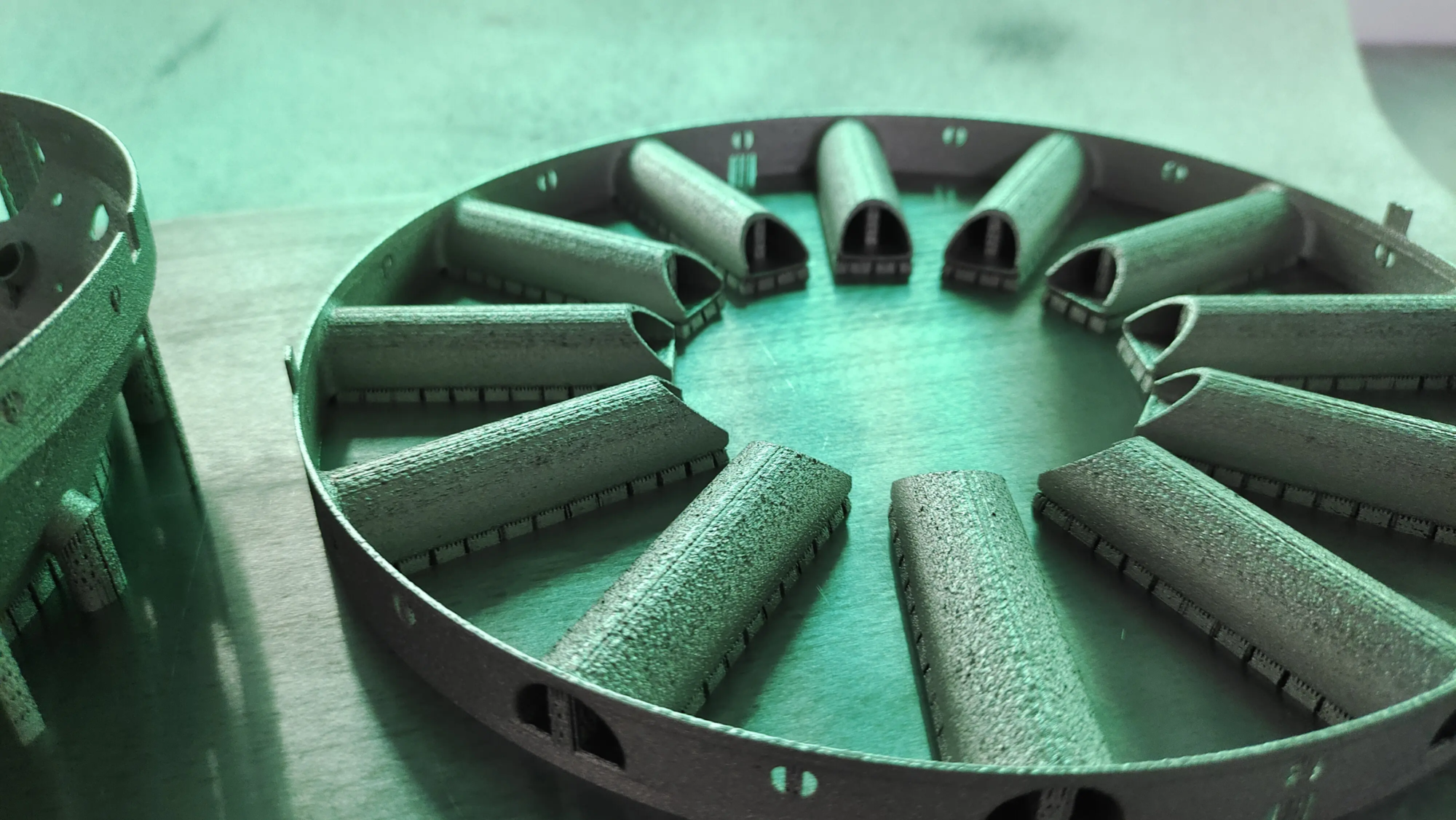

- Metal (SLM/Binder Jetting – Professional Services): True authenticity and durability.

- Services like GreatLight Technologies use selective laser melting (SLM) to create strong, high-density metal parts.

- Stainless steel, titanium or aluminum provide unparalleled realism, weight, longevity and true "metal villain" Feel.

- Key Tips: Complex masks with fine detail or metal requirements often require industrial-grade printers and expertise. Outsourcing ensures structural integrity and material correctness.

3. Successful Slicing Setup (Focus on Plastics)

Achieving a smooth surface minimizes sanding:

- Floor height: Low and slow (0.1mm-0.15mm), achieving smooth curves.

- filling: High density (30-50%) ensures rigidity without adding excessive weight.

- support: Basic! Use tree supports or custom generated supports in the slicer to handle dramatic overhangs (chin, forehead curves). Set the support interface density higher to get clearer breakpoints.

- Print speed: Slow down the speed (30-50mm/s) to enhance layer adhesion and surface quality, especially on curves.

- cool down: Maximize cooling of parts to prevent sagging on steep overhangs.

4. Master Post-Processing: Transformation is Key

This stage separates great prints from exceptional props:

- Support removal: Use flat end mills carefully. Carefully sand away any remaining bumps.

- Polishing: Start sanding coarsely (120-200 grit) to gradually eliminate layer lines. Improve optical smoothness by wet grinding to a finer grit size (400 -> 800 -> 1000+). Patience is non-negotiable.

- filling: Use styling putty/site putty/Bondo to patch pinholes or imperfections. Sand smooth after curing.

- Primer: High-fill primer spray coats create an even base coat and reveal hidden imperfections. Sand lightly between coats.

- Painted metal: Achieve real effects:

- Primer: Universal gray primer.

- Metal base: high quality silver/chrome spray paint.

- "second hand metal" Effect (optional): Apply a thin coat of black/brown acrylic water into the gaps and erase the high spots to create weathering and depth.

- Clear Coat: Protect your work with a matte or satin clear coat.

5. Assembly (multi-part design)

For segmented masks:

- Make sure the pins/holes line up perfectly.

- Use a strong adhesive: epoxy, plastic welding or CA glue (superglue) with activator.

- If needed, reinforce stress points internally with epoxy putty.

- Soft padding is inserted around the forehead and bridge of the nose to ensure comfort and stability while wearing.

Conclusion: Show your evil with pride

Making the MF DOOM masks via 3D printing has been a rewarding journey – part technical challenge, part artistic expression. While desktop printing provides an accessible path, achieving museum-quality realism (especially with metal printing) requires capabilities beyond the typical hobbyist setup.

(Subtle integration begins:)

For enthusiasts seeking the pinnacle of craftsmanship—with true metal weight and structural integrity reflecting the majesty of DOOM—and Professional rapid prototyping manufacturers like Ferrite Technology elevate projects to the next level. their expertise Industrial-grade SLM metal 3D printing Allows for intricate designs in durable stainless steel or titanium, transforming digital files into cold, flawless reality. Combine their synthesis Post-processing services Including meticulous finishing, polishing and custom finishes, GreatLight expertly solves complex prototyping challenges. Does your vision require plastic prototype iterations?