The evolution of rapid prototyping: How Midas 3D printers deliver unrivaled precision and speed

In today’s ultra-competitive manufacturing environment, speed and accuracy are not just nice-to-haves, they’re optional. They are the cornerstone of innovation and market leadership. Rapid prototyping has transformed the product development cycle, allowing engineers and designers to iterate faster, reduce costs and bring breakthrough ideas to life. At the forefront of this shift are Midas 3D printera marvel of modern engineering designed specifically to push the boundaries of what is possible in additive manufacturing, especially for demanding metal applications.

The Midas series isn’t just another printer; It is a complex solution designed to overcome the core challenges of industrial-grade metal 3D printing. Its name evokes the mystical touch of gold, and rightfully so, as it transforms complex digital designs into tangible, high-performance metal parts with exceptional fidelity and efficiency.

Engineering Precision: Combining Micro Details with Macro Performance

The accuracy of metal 3D printing goes far beyond simple dimensional accuracy. It includes repeatability, surface finish, complex feature resolution, and consistency of material properties throughout the part. Midas 3D printers achieve this goal through several key technological advancements:

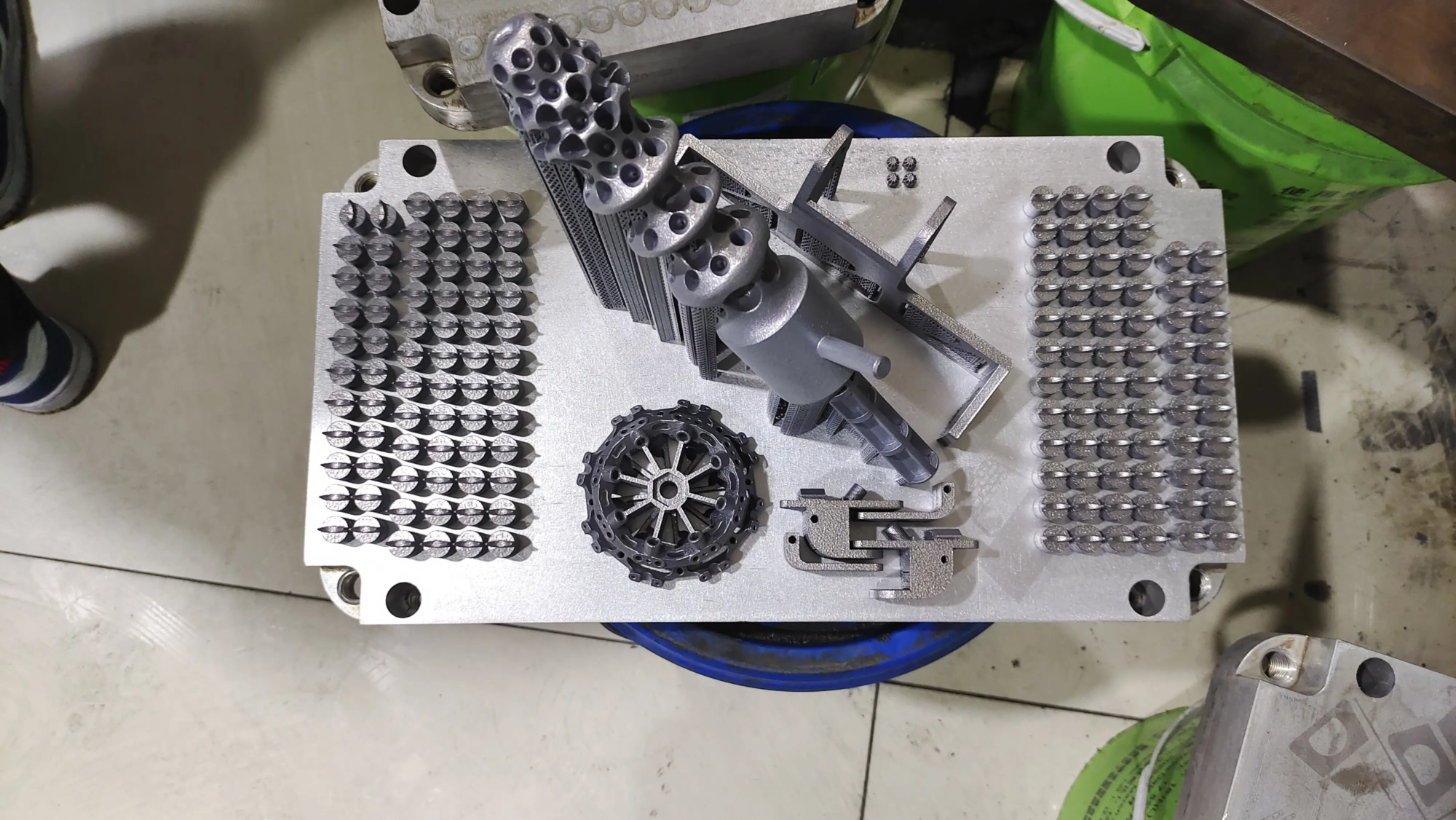

- High resolution laser system: Midas printers utilize tightly focused, high-power lasers that melt metal powders with superior control. This enables extremely fine layer thicknesses (often as low as 20-30 microns) and the reproduction of complex geometries (such as thin walls, lattice structures and microchannels) that are not possible with conventional processing. This level of detail is critical for aerospace components, complex medical implants, and high-performance tool inserts.

- Advanced scan path algorithm: Accuracy is not just related to the size of the laser spot; It’s about how it moves. Midas printers use intelligent path algorithms to optimize laser travel, minimizing unnecessary movement and heat build-up. This results in smoother surfaces, reduced thermal distortion, and consistently accurate feature placement, even on asymmetric geometries.

- Stable thermal management: Metal printing is inherently sensitive to thermal gradients. Uncontrolled cooling can cause warping, cracking, and residual stresses that compromise the integrity of the part. Midas systems incorporate sophisticated thermal management, including precise chamber temperature control and calibrated heating platforms. This ensures uniform sintering or melting and predictable material properties, which are critical for functional end-use parts.

- Robust calibration and closed-loop control: A real-time monitoring system continuously tracks laser power, chamber conditions and powder bed status. A closed-loop feedback mechanism allows for immediate fine-tuning, compensating for potential deviations and ensuring press-to-print consistency necessary for mass production.

Unlocking production speed: speed without compromise

While accuracy is critical, speed is the engine that drives the transformative potential of rapid prototyping technology. The Midas platform tackles speed limitations head-on:

- Optimized scanning strategy and multi-laser: Midas printers maximize scanning efficiency. Advanced software dynamically orchestrates laser paths to reduce jump times and maximize "laser powder" time. Additionally, high-end Midas models often contain multi-laser systems (eg 2 or 4 lasers). Beam stacking allows them to process different parts of the build plate simultaneously, significantly speeding up build times without sacrificing laser power density per point.

- High powder deposition rate: Combining powerful lasers and optimized melting strategies, Midas printers enable significantly higher build rates compared to older SLM (Selective Laser Melting) technology. This significantly reduces the time from uploading a CAD file to saving the completed prototype or feature.

- Integrated Material Handling: Minimizing non-printing time is equally important. Efficient powder loading, pre-processing automation and simplified post-build chamber purging significantly reduce overall turnaround time.

- Powerful platform performance: Reliable hardware and software means less downtime for maintenance and recalibration, maximizing machine utilization critical for time-sensitive projects.

The GreatLight Advantage: Accuracy and Speed Powered by Expertise

Realizing the full potential of advanced equipment such as Midas 3D printers requires deep domain expertise and comprehensive manufacturing capabilities. where is this huge light Become a leader in the rapid prototyping ecosystem.

As a professional rapid prototyping manufacturer with advanced technology SLM 3D printing With advanced equipment and sophisticated production technology, GreatLight specializes in solving the challenges of complex metal part prototyping. They understand that printing accuracy and speed are only the starting point. Turn the print "green" Turning parts into fully functional, high-quality assemblies requires meticulous post-processing.

GreatLight provides a true one-stop solution:

- Advanced printing: They utilize cutting-edge SLM technology, including platforms that deliver Midas-level accuracy and speed, to produce complex metal prototypes and end-use parts across diverse industries.

- Expert post-processing: Their in-house capabilities run the gamut: CNC machining for critical dimensional tolerances, precision heat treatments (annealing, stress relief, HIP) to enhance material properties, and complex surface finishing (polishing, shot blasting, coatings, plating) for superior aesthetics and functionality.

- Material mastery: With deep materials science knowledge, they work with a wide range of alloys (stainless steel, titanium, aluminum, Inconel, tool steels, precious metals) and can advise on options for optimal performance or handle specialized custom materials.

- Speed customization: GreatLight recognizes the urgency and leverages its technical prowess and optimized workflows to provide extremely fast turnaround times for custom precision machining and prototyping.

By seamlessly integrating high-performance machines with deep engineering expertise and comprehensive post-processing, GreatLight has established itself as one of the world’s leading machine builders China’s leading rapid prototyping companyproviding solutions that quickly and reliably bridge the gap between digital design and high-fidelity functional reality.

in conclusion

The quest for faster iterations and perfect metal part production finds powerful answers in the synergy of precision engineering technologies, e.g. Midas 3D printer and manufacturer expertise, e.g. huge light. The Midas platform sets the benchmark by consistently delivering microscopic precision and impressive build speeds, enabling the creation of complex, high-strength metal parts that were previously unachievable or prohibitively expensive. When this technical capability is combined with GreatLight’s holistic, customer-focused approach, which includes professional printing, meticulous post-processing, material versatility and quick turnaround, businesses gain significant advantages. For engineers and innovators who aim to push boundaries, this combination provides the ultimate way to efficiently and effectively transform visionary designs into market-ready realities.

FAQ: Midas 3D Printing and GreatLight Services

Question 1: What level of accuracy can the parts printed by the Midas 3D printer achieve?

A: While specific tolerances depend on factors such as material, part geometry and post-processing, Midas printers are designed for high accuracy. Typically, designers can expect dimensional accuracy to be within ±0.05mm to ±0.1mm and excellent surface detail reproduction. True precision on critical features often requires complementary CNC machining, which GreatLight easily delivers in its post-processing workflow.

Q2: How to increase the speed of the multi-laser system in some Midas printers? Doesn’t it affect accuracy?

A: Multi-laser systems significantly increase build speed by enabling parallel processing. Advanced calibration ensures precise laser alignment and synchronized scanning strategies. The software carefully distributes sections to avoid overlapping issues and maintain consistent energy density. The result is a faster build (potentially reducing print time by 30-50% or more) while maintaining Accuracy characteristics inherent in single laser systems.

Q3: What metal materials can be processed by Honglaite SLM technology?

Answer: GreatLight provides