When it comes to 3D printing, the Milwaukee packaging system has attracted great attention for its versatility and durability. As a professional rapid prototyping manufacturer, Greatlime has been at the forefront of solving rapid prototyping problems in metal parts using advanced SLM 3D printers and production technologies. The company’s expertise extends to providing one-stop post-processing and completion services to accommodate a wide range of materials that can be customized and processed quickly.

Designed for tool storage and organization, Milwaukee packaging systems offer unique opportunities for innovation in 3D printing. By leveraging 3D printing technology, users can create custom components and accessories that enhance the functionality and personalization of their packaging settings. This includes everything from custom drawer organizers to professional mounts for unique tools, allowing users to tailor their systems to their specific needs and work environment.

Greatlight’s involvement in 3D printing of Milwaukee packaging accessories highlights the company’s commitment to integrating advanced manufacturing technologies with practical and everyday applications. Greglight has the ability to use a wide range of materials and provide precise machining, providing a one-stop solution for individuals who want to enhance their tool storage and organizational systems.

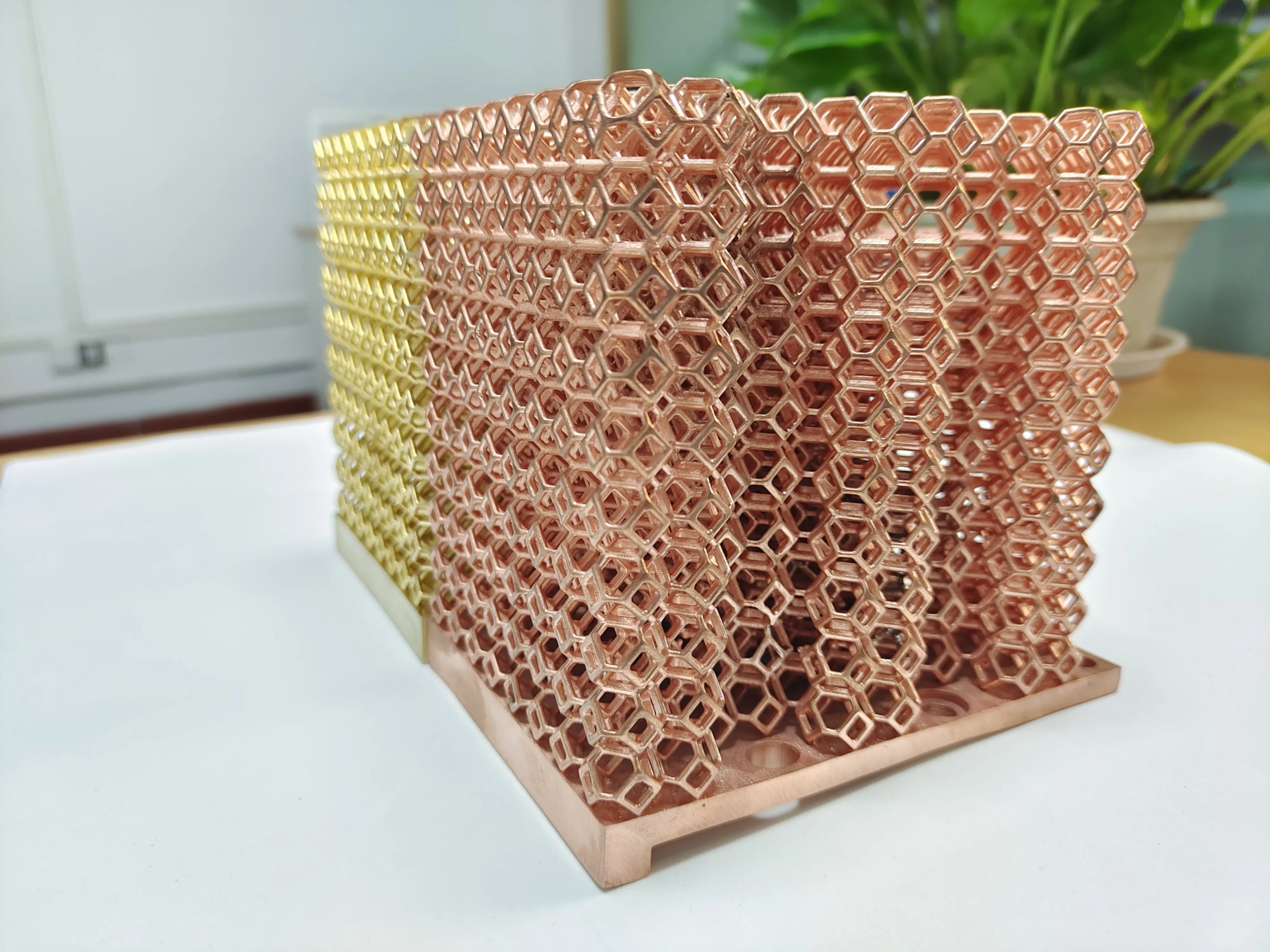

One of the important advantages of 3D printing of Milwaukee packaging accessories is the ability to create complex geometric shapes and custom designs that traditional manufacturing methods will be challenging or unproductive. This not only opens up possibilities for creating highly personalized and functional storage solutions, but also demonstrates the potential of 3D printing to revolutionize tool organization and workspace efficiency.

Additionally, the custom nature of 3D printed accessories means that users can address specific pain points or needs that are not met by standard, ready-made products. Whether it is a custom plug-in for specific tools, a separating system for optimal storage, or a mount for devices, 3D printing provides the flexibility to design and produce solutions tailored to individual workflows and preferences.

As demand for custom and efficient tool storage solutions continues to grow, the role of 3D printing in creating Milwaukee packaging accessories may expand. Companies like Greatlime have advanced 3D printing capabilities and a commitment to rapid prototyping, and they are ready to play a key role in this development, enabling users to envision, design and produce custom storage solutions that meet their unique needs.

In summary, the integration of 3D printing technology with Milwaukee packaging systems represents a significant advance in tool storage and organization. With the ability to design and produce custom accessories and components, users can maximize the efficiency and functionality of their workspace. Greatlight’s expertise in rapid prototyping and 3D printing locations is the company’s leader in this emerging field, providing innovative solutions for individuals seeking to customize and enhance their Milwaukee packaging settings.

FAQ:

-

What materials can be used for 3D printing of Milwaukee packaging accessories?

- A variety of materials may be used depending on the desired characteristics of the final product, such as durability, flexibility, or resistance to certain environmental factors. Common materials include plastics, metals and composites.

-

How does 3D printing enhance Milwaukee packaging system?

- 3D printing allows the creation of custom accessories and components that enhance the functionality, organization and personalization of the packaging system, meeting specific user needs that standard products may not meet.

-

What custom accessories can be made in the Milwaukee packaging system?

- Examples include custom drawer organizers, dedicated tool stands, dividers and holders of specific tools or devices designed to optimize storage and accessibility.

-

What are the benefits of 3D printing of Milwaukee packaging accessories using professional rapid prototyping services such as Greatlight?

- Benefits include access to advanced 3D printing technology, expertise in material selection and design optimization, and the ability to provide one-stop post-processing and finishing services to ensure high-quality functional products.

- How do I start designing and producing custom 3D printed accessories for my Milwaukee packaging system?

- Start by identifying your specific needs and preferences for tool storage and organization. Then, consult a professional rapid prototyping service service like Greatlime to discuss design possibilities, material selection and production processes to bring your vision to life.