Beyond plastic prototypes: Unlock realism with Mimaki full-color 3D printing

The world of 3D printing has evolved far beyond monochromatic prototypes and basic functional parts. Mimaki is at the forefront of this color revolution, leveraging its strong heritage in inkjet technology to redefine what is possible in additive manufacturing. Mimaki’s full-color 3D printing technology isn’t just about adding a bit of paint; it’s about achieving stunningly realistic detail, texture, and vibrancy directly during the build process. Let’s take a closer look at how this innovative process works and why it’s important.

The magic behind Mimaki full color

At the heart of Mimaki is a powder-based binder jetting process combined with UV-LED curing technology, a signature shift in their expertise:

- Fine powder bed: A thin layer of specialized gypsum-based composite powder is evenly distributed over the build platform.

- Inkjet color applications: Multiple piezoelectric printheads pass through the powder bed. Crucially, instead of spraying a colorless adhesive, they deposit tiny droplets of a unique UV-curable liquid photopolymer resin. Cyan, magenta, yellow, black (CMYK) and clear. This allows for precise color mixing on a pixel-by-pixel basis on the surface of the powder.

- Instant UV Curing: This is where Mimkey’s key innovation lies. As the CMYK(+Clear) resin drops drop, they are immediately cured and solidified by high-intensity UV LED lamps mounted on the print carriage. This quick fix instantly locks in the precise color and geometry of the layer.

- Bonding: The liquid resin acts as both a colorant and a binder. At the point of deposition, it saturates the powder particles and locally fuses them together after solidification.

- Layer by layer: The build platform is lowered, a new coat of powder is applied, and the process repeats: paint, UV cure, bond. This continues until the entire object is formed within the powder bed.

- Post-processing: Once finished, carefully scoop the part out of the surrounding loose powder. Use a brush and compressed air to remove excess powder. For maximum mechanical strength and vibrant color stability, parts are infiltration. This involves dipping the part in a special cyanoacrylate resin (similar to superglue, but optimized) and possibly applying a clear coat spray to enhance shine and durability.

Why Mimaki Full Color Stands Out: Key Features and Benefits

- Unrivaled Reality: CMYK color mixing combined with the printhead’s high resolution (up to 1200 dpi) and clear resin for transparency effects and varnish simulations results in incredibly detailed and realistic color reproduction. Gradients, textures (wood grain, stone, fabric) and even photographic images can be reproduced with extremely high fidelity.

- Speed and efficiency: Compared to some other full-color technologies, the UV-LED curing step is very fast, enabling rapid layer formation and significantly reducing overall print time.

- Design freedom: Handle complex geometries, internal voids, and fine details naturally without the need for additional support structures during the printing process (the surrounding powder acts as a support).

- Surface finish: Post-penetration parts have a smooth, matte to satin finish ideal for visual applications. Clear resin applications can simulate clear windows or glossy surfaces.

- Material Versatility: Although specialized gypsum composites are primarily used, Mimaki offers a variety of substrates optimized for different properties such as flexural strength or reinforced detailing.

Where Mimaki shines in full color (the sweet spot)

The technology excels in applications that require high visual impact and intricate detail rather than extreme mechanical strength or thermal resistance:

- Hyper-realistic prototype: Communicate design ideas visually and emotionally, bridging the gap between digital models and physical products. Ideal for ergonomic studies, consumer packaging models with labels, architectural models with landscaping, and more.

- Medical model: Highly detailed anatomical models derived directly from CT or MRI scans for surgical planning, patient education, and medical training. Color coding different tissues provides great clarity.

- Marketing and Sales Tools: Eye-catching promotional mockups, functional product demonstrations that look identical to the final product, museum exhibits and point-of-sale displays.

- Personalized products: Custom statues, architectural scale models with realistic textures, and commemorative items that require detailed photos embedded into 3D artwork.

- Special effects and props: Quickly create detailed props for film, theater and entertainment venues where visual appearance is critical.

Important considerations and limitations

- Material properties: Post-penetration parts are rigid but relatively brittle compared to engineering thermoplastics or nylon sintered powders. They exhibit good compressive strength but low impact strength and flexural modulus. They are not suitable for functional parts subject to high stresses, repeated loads, high temperatures, or prolonged outdoor UV exposure.

- Delicate processing: Prepenetration ("green") parts are very fragile. Even post-penetration parts require gentler handling than metal or solid plastic parts.

- Penetration key: The penetration step is critical to achieving ultimate strength and color stability. The unpenetrated portion remains fragile and powdery.

Conclusion: A dynamic addition to your prototyping library

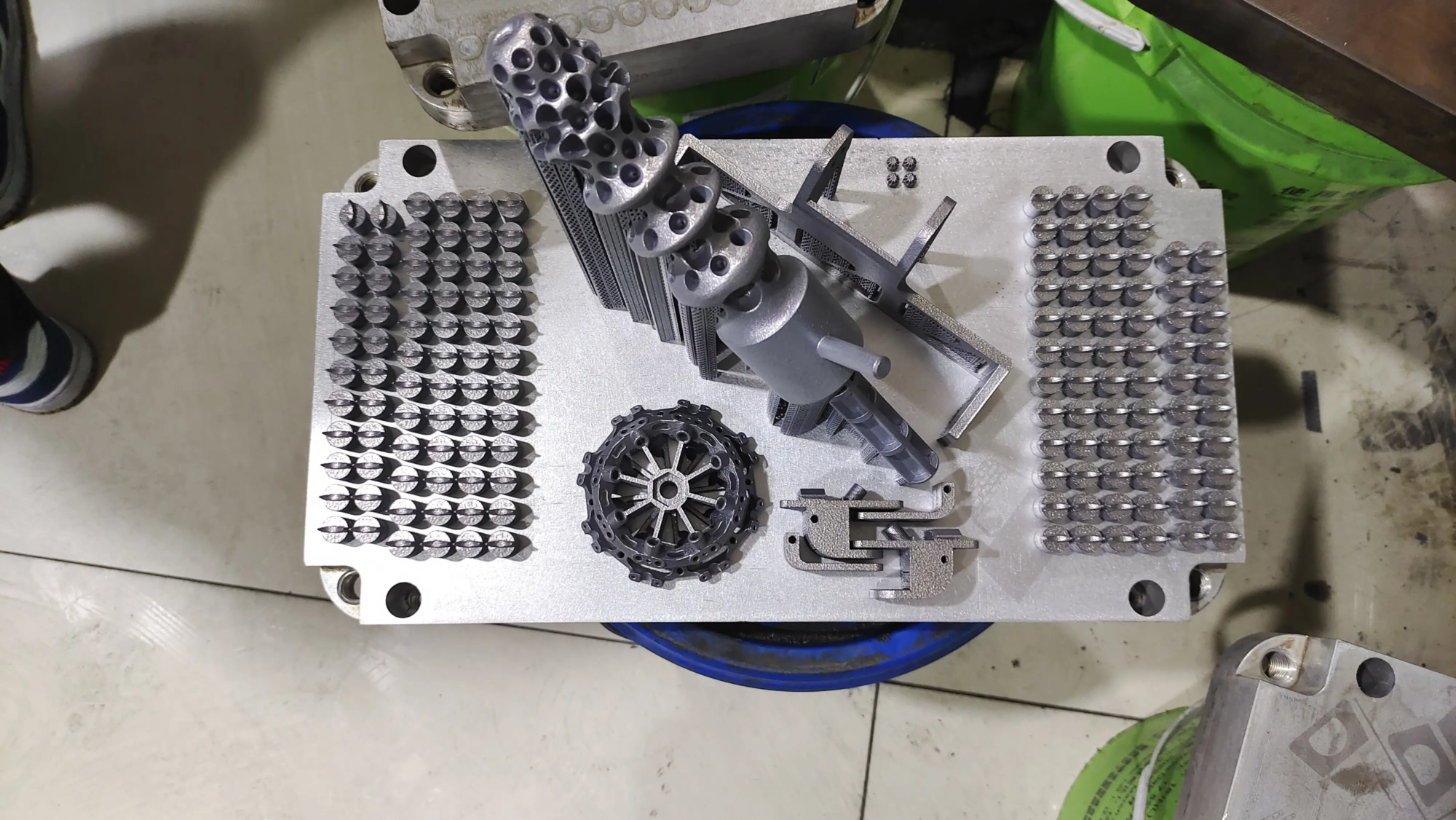

Mimaki full-color 3D printing is not a replacement for functional prototyping methods such as SLS, FDM or SLM metal printing. Instead, it carves out a unique niche as the most important solution Visual communication and stunning realism. Its ability to produce parts that look and feel extremely lifelike directly from the printer makes it an invaluable tool for designers, marketers, medical professionals, educators, and artists.

For applications that prioritize aesthetic fidelity, intricate detail, quick turnaround, and tangible impact, Mimaki’s technology offers capabilities unmatched by other 3D printing processes. It transforms digital designs into vivid, persuasive and communicative physical objects faster than ever before.

FAQ: Mimaki Full Color 3D Printing

Q1: Is Mimaki printing suitable for functional and load-bearing parts?

Answer: Generally speaking no. While the parts gain considerable strength through infiltration, Mimaki’s full-color prints (mostly plaster-based) are best suited for visual and prototyping applications. They lack the toughness, heat resistance and long-term durability required for demanding functional applications. For functional prototypes or end-use parts that require strength, toughness, or heat resistance (especially in metals), processes such as Selective Laser Melting (SLM), SLS (nylon), or MJF/FDM with engineering polymers are more suitable.

Q2: How long can Mimaki color printed pudding be kept? How color fast are they?

A: Properly penetrated components can last for years when placed indoors, away from direct sunlight and excessive moisture. Cyanoacrylate penetration significantly stabilizes the color pigments trapped in the cured resin and molten powder. However, prolonged exposure to strong UV rays (such as direct sunlight) may cause the color to fade over time, similar to printed photos or dyed fabrics. Clear coats may provide limited initial protection against scratches and moisture absorption.

Q3: What kind of detail resolution can I expect?

A: Mimaki systems have very high print resolution – up to 1200 dpi. This results in extremely fine detail, crisp text down to point size, smooth gradients, and excellent reproduction of complex surface textures. The addition of clear resin further enhances detail by simulating transparency and varying gloss levels.

Q4: How complex shapes can it produce?

A: Powder-based adhesive jetting excels in complexity. The unprinted powder surrounding the part acts as its own support structure during the build process. This enables the printing of complex geometries, internal channels, delicate features, undercuts and hollow sections that are either impossible or require complex supports in other technologies such as FDM or SLA. Excavation may require attention to very fine internal features.

Q5: How are the printed parts completed?

Answer: Post-processing involves two key steps:

- Remove powder: Remove loose trigger powder from the build chamber and gently clean the part using a brush and compressed air.

- infiltration: This is basic. Parts can be dipped or sprayed in clear cyanoacrylate resin. This penetrates into the pores between the molten powder particles, significantly increasing strength (compressive and tensile), stabilizing color, and improving surface integrity/handling. A final coat of varnish (like sealer/acrylic) is often used to enhance shine, slightly improve moisture resistance, and provide a smoother feel. Infiltration takes time (usually at least a few hours) and requires proper ventilation.

Q6: Is Mimaki full-color printing expensive?

A: Cost depends heavily on part size, geometry complexity, color usage, penetration type, batch size and service provider. While there is already a time/material cost to the machine, achieving high realism inherently requires complex processes and materials. It is very competitive with the cost and time of tearing down painted prototypes or molds to produce low-volume, high-detail parts. It’s ideal for low-volume, geometrically complex visual projects where adding accurate color manually would be very expensive or time-consuming.

Q7: In addition to standard plaster, what other materials are available?

A: Mimaki offers a slightly different recipe. While all products are primarily gypsum powder composites infused with a CMYK+Clear UV resin system during the printing process, there are differences. Some formulations prioritize higher flexural strength before penetration, or allow for finer detail resolution. Please consult a service provider such as GreatLight for specific material options and properties.

Interested in the possibilities of full-color photo realism?

At GreatLight, while our primary expertise lies in precision metal prototyping using advanced SLM technology and comprehensive post-processing services, we recognize the revolutionary role Mimaki full-color 3D printing can play in visual communication.

For projects that require stunning aesthetic detail, rapid visual prototyping, or high-precision anatomical or architectural models, Working with a specialist provider of Mimaki technology is often the best approach. Understanding the benefits and limitations of each additive manufacturing process allows us to guide our customers towards The most effective solutionwhether it’s a solid metal functional prototype produced via in-house SLM, or a museum-quality detailed color model produced externally using Mimaki. **

Let GreatLight solve your complex structural prototypes and metal parts. When extreme visual fidelity is the primary need, we can help you understand the benefits of Mimaki full-color printing or advise on the best overall approach for your unique challenges. [Contact GreatLight] Explore the possibilities for your next project!