Embrace the miniature charm: the world of 1:64 scale 3D farm toys

The charm of the country, the buzz of machinery and the dedication of agricultural life make for an eternal obsession. For enthusiasts, collectors and children, capturing this essence in miniature forms is a unique joy. Enter the world 1:64 Scale 3D Farm Toys – Complex replicas that bring the vast expanse of the farm to your fingertips. These are more than just playback; they are detailed diorama works, collectible treasures and educational tools to celebrate agriculture with amazing details.

Why 1:64 Scale Dominates Supreme

The 1:64 scale is usually represented as about 1:87 in Europe, but is a popular standard in North America (think brands like ERTL Precision) that provides the perfect balance:

- Manageable sizes: These models are roughly suited to your palm (the tractor is 2-3 inches long), and these models are easy to handle, display and store, making them perfect for gaming and collection.

- Uncompromising details: On this scale, manufacturers, especially modern 3D printing technology, can blend extraordinary precision. Engine components, sophisticated hydraulic lines, realistic tire treads and authentic paint schemes become visible micro feats of engineering.

- Scene construction magic: Standardized scales are easily compatible. Combine tractors, combines, trailers, tools, barns, animals and various manufacturers to create dynamic, cohesive farmhouse scenes on a desktop or dedicated shelf display.

- Accessibility and diversity: 1:64 is one of the most popular performance and model scales in the world, ensuring a huge range of classic vintage tractors covering the latest high-tech agricultural machinery.

The 3D printing revolution in micro-agriculture

Traditional die-cast metals and injected plastics dominate the mass market, but Advanced 3D printing technology The landscape is being transformed, unlocking unprecedented possibilities for farm toy creation and customization. This is what the company likes Great Stepping into the picture, showing the potential of more than just hobby printers.

As a professional rapid prototyping manufacturer, great lamps have the most advanced SLM (Selective Laser Melting) 3D Printer and deep production expertise. This is very important for farm toy lovers and seeking manufacturers:

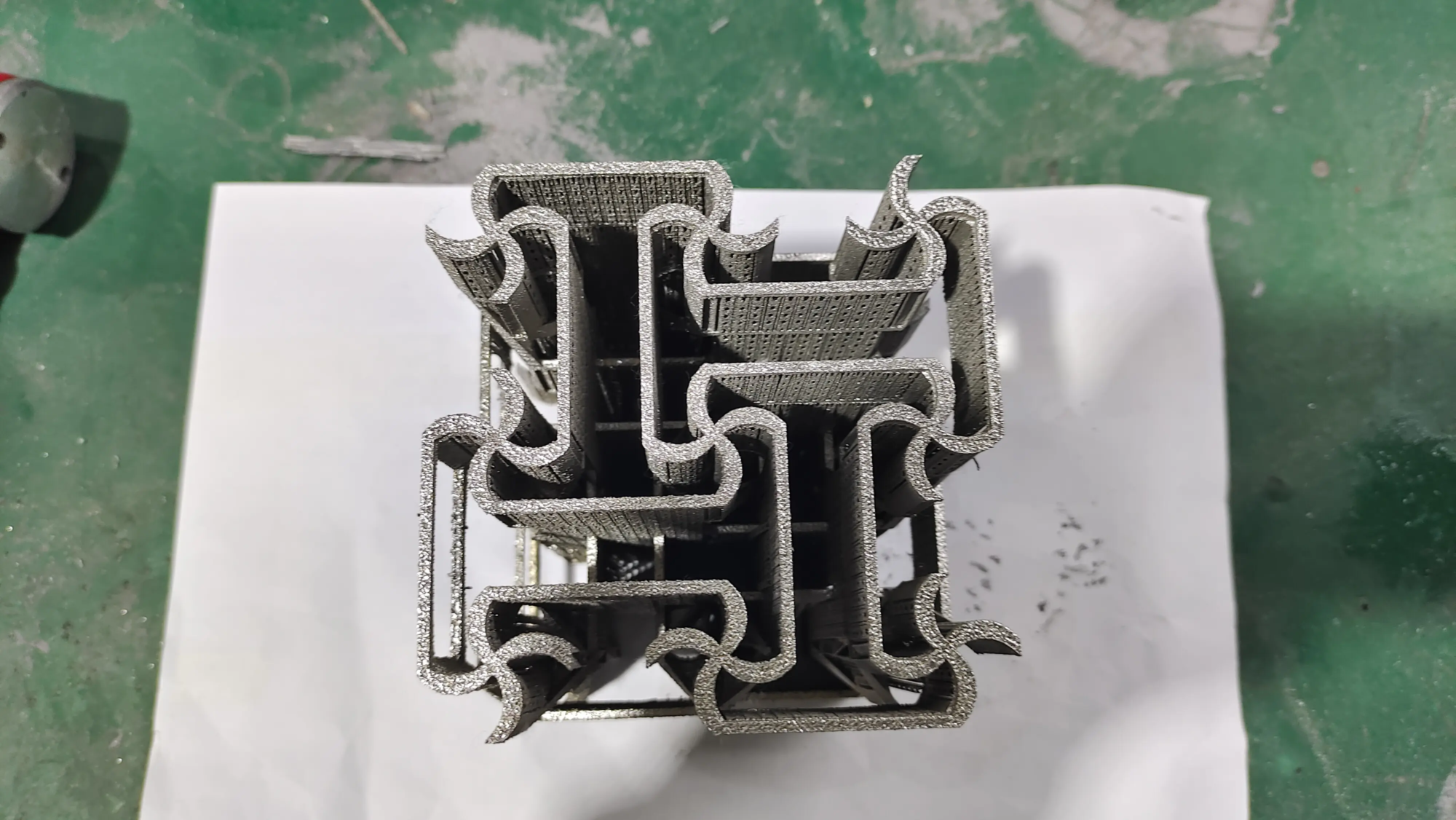

- Ultra-high precision and details: SLM printing uses powerful lasers to build models from fine metal powders (such as stainless steel, aluminum alloys). This creates complex geometric shapes and microscopic details through traditional molding – think of intricate grilles, realistic engine blocks, tiny mobile connections, and similarly beautiful decal surface textures for printed Enter Metal. Imagine a miniature John Deere combined with the replicated actual grain chute mechanism!

- Unrivaled durability and feel: Compared to plastics, metal 3D printed parts have superior structural integrity and satisfactory weight. These toys are durable and can resist damage from treatment or accidental drops, making them suitable for careful game scenes that are purely displayed.

- Real custom release: Want a specific, hard to find retro tractor? Need a rare implementation of perfect scaling? Dreaming of a personalized tractor with the name of a family farm? 3D printing can enable real custom creation. Greatlight’s rapid prototyping converts 3D design files into custom metal masterpieces, quickly and accurately. Most materials can be tailored to the specific weight, finish and aesthetics you need.

- Rapidly innovate prototypes: For toy designers and manufacturers, Greatlime facilitates rapid iteration. A new tractor design concept can be tested quickly (rather than months) in metal form, function and scaling accuracy, faster than ever before, and can accelerate market time for new models.

- Seamlessly done: Greatlight understands that original printing is just the beginning. Their One-stop post-processing and completion service It is crucial to turn a print into a premium collectible. This includes disassembly expert support, precise machining of critical interfaces, detailed surface smoothing (polished, tumbling), and high-quality painting or plating – for a realistic showroom-ready finish.

Beyond the Game: The Value of Micro Agriculture

These carefully crafted 1:64 scale models can achieve a variety of purposes:

- collect: For many, it is a passion. Finding rare models, completing series or focusing on a specific brand and era becomes a meaningful hobby.

- educate: They provide a tangible, engaging way to teach children (and adults!) about different farm equipment, their functions and the basics of agriculture.

- History preservation: Retro tractor models retain the design and engineering legacy of past agricultural eras.

- Diorama and Storytelling: Enthusiasts build beautiful miniature farm scenes, tell stories and reproduce farm life with complex details.

- Decoration: Elaborate models can be highlighted by launching unique and start-up table decorations or display cabinets.

in conclusion

The world of 1:64 scale farm toys offers a fascinating blend of nostalgia, engineering appreciation and creative expression. The emergence of advanced metal 3D printing, supported by expert rapid prototyping manufacturers Greatis breaking through possible boundaries in this micro-field. It enables unprecedented levels of detail, durability and customization – changing the conceptualization, prototype and production of unique, high-fidelity farm models. Whether you are an experienced collector, looking for impossible work, manufacturers innovate the next iconic model, or be fascinated by the miniature miracles of modern agriculture, the fusion of traditional scale modeling passions with cutting-edge 3D manufacturing is exciting cutting-edge. The future of microfarms is precise, personalized, and extremely durable.

FAQ: Your Mini 3D Farm Toy Question Answer

Q1: What’s there "1:64 ratio" What does it actually mean?

A1: This means that the model is 64 times smaller than real-life objects. For example, if a full-size tractor is 20 feet (240 inches) long, its 1:64 scale model will be 240 /64 = 3.75 inches.

Q2: Are 3D printing farm toys as durable as traditional die-cast metal toys?

A2: When printing using professional metal 3D printing technology such as Greatlight (such as SLM (selective laser melting)), the resulting metal parts can be extremely Durable, usually with mass or exceeding the strength of some traditional cast alloys. The printing process and the quality of the materials used are crucial. Plastic 3D printing (FDM/resin) is generally not as good as metals for treatment.

Question 3: Can I really make a completely custom farm toy? Like a person who doesn’t exist?

A3: Absolutely. This is the main advantage of 3D printing. Professional rapid prototyping services such as Greatlime specialize in converting custom 3D designs into physical metal parts. If you have a detailed 3D model of unique designs (CAD files) – whether it’s a custom tractor, implementation of specific changes, or even a personalized model with a brand), they can make it precisely.

Question 4: Is metal 3D printing too expensive for toys?

A4: For mass-produced toys, traditional methods are still more cost-effective. But, Customized, small batch production, high-detailed prototypes or ultra-rare replicasmetal 3D printing becomes a very feasible and often unparalleled solution. The cost reflects the nature of customization, the advanced technology used, and the superior material/metal finish. Greatligh’s focus is on providing The best Customize precision parts at competitive prices.

Q5: Which decorative choice can be used for 3D printed metal farm toys?

A5: Expert post-processing is the key. Like the services provided by Greatlight, usually include:

- Support removal: Carefully remove the scaffolding used during the printing process.

- Processing: Accurate completion of critical surfaces or holes.

- Surface smooth: Polish, beads blast or tumbling to achieve the desired texture (matte, satin, smooth).

- painting: High fidelity, durable paint app matches authentic branded colors or custom solutions.

- plating: Options such as chrome plating for exhaust or specific parts.

- detail: Add decals, tiny lenses of the lighting, etc.

Question 6: How fast is the turnover of customized 3D printing farm models?

A6: "Rapidly" It’s the key! While traditional manufacturing takes several months, the speed of professional rapid prototyping companies such as Greatlight Excel. Transformation is usually only a few days to weeks, depending on complexity, post-processing requirements and current workload. This allows very fast design verification and production of customized works or prototypes.

Question 7: What are the benefits of these metal 3D printing services besides farm toys?

A7: Greglight’s advanced SLM printing and completion services are ideal for any industry that needs it High precision, complex custom metal parts. This includes aerospace components, automotive prototypes, intricate medical equipment, professional engineering parts, functional prototypes for consumer products, and unique architectural models – essentially where strength, detail, complex geometry and customizability are crucial. But for those in the farm world, it unlocks miniature miracles.