Synopsis: When flames grow miniature and gigantic in metal

Once every four years, the Olympic flame ignites global enthusiasm and symbolizes peace, friendship and the pinnacle of sporting achievement. The torch relay carrying the iconic flame becomes a spectacular journey watched by millions. Capturing this magical moment is a dream for many – and thanks to the revolutionary capabilities of additive manufacturing, specifically metal 3D printing, owning a tangible, miniature piece of Olympic history is no longer just a fantasy. The Mini 3D Printed Olympic Torch blends timeless tradition with cutting-edge manufacturing, appealing to collectors and technology enthusiasts alike.

The Olympic Torch: An Evolving Symbol

Designing the Olympic torch is a major task for each host country. It had to be visually stunning, rich in symbolism, energy efficient, windproof and durable enough for a global relay race. From the bamboo design of Tokyo 2020 (2021) to the intricate, fragmented aluminum structure of Rio 2016, each torch is a marvel of engineering and design. Traditionally, producing replicas, especially complex miniatures, has been complex, costly and often limited due to the limitations of traditional manufacturing techniques such as casting or subtractive machining. This is where modern 3D printing comes onto the podium.

The rise of mini 3D printed torches: Small scale, big impact

Miniature Olympic Torch replicas serve as valuable collectibles, unique awards, inspiring educational tools or powerful promotional items. They represent aspirations, achievements and a spirit of togetherness. Until now, creating these complex miniatures accurately and aesthetically using traditional methods has often been cost-prohibitive for low-volume or custom designs.

3D printing, especially Selective Laser Melting (SLM)has become the champion technique for making these miniature icons. Here’s why:

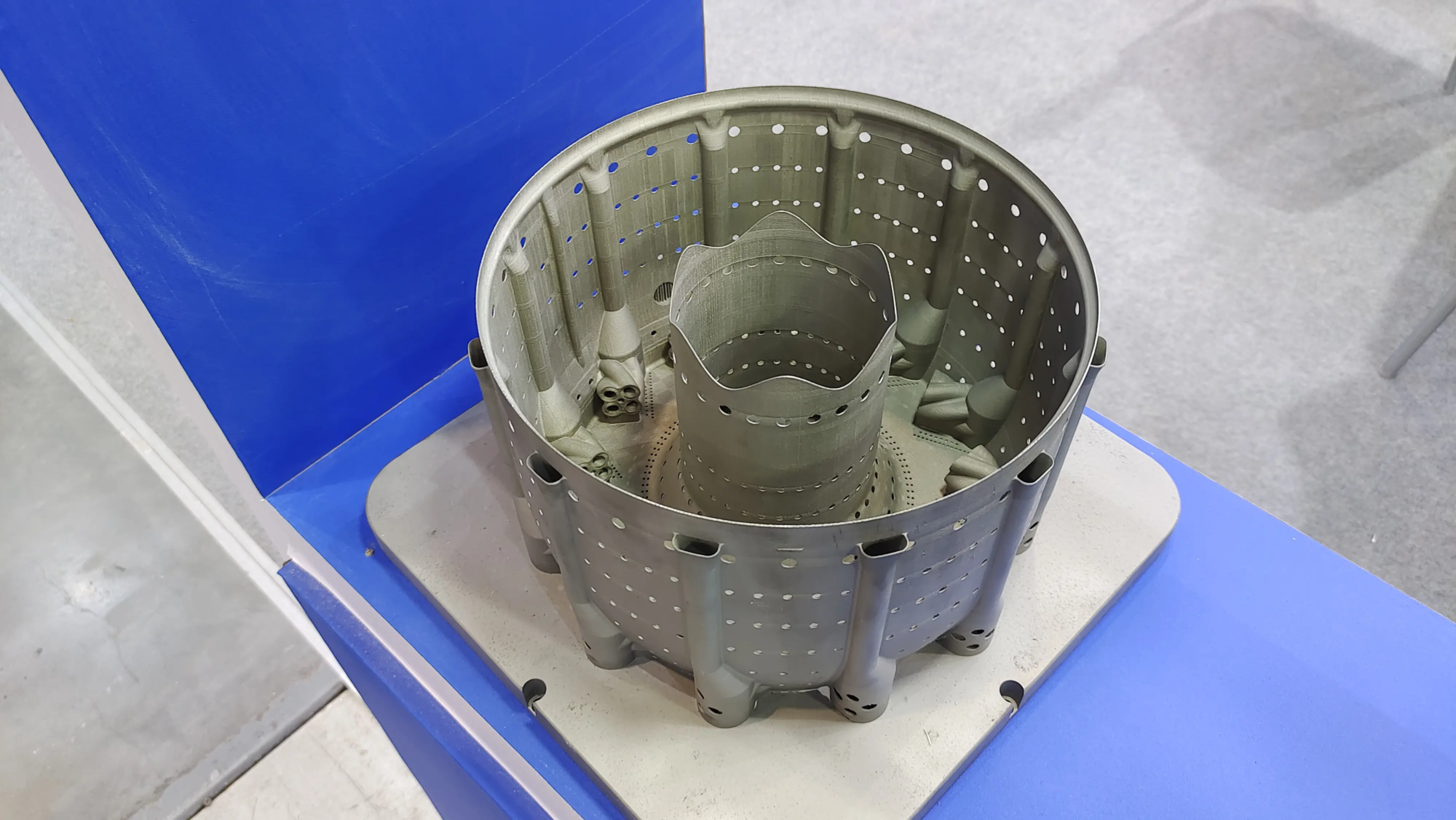

- Unparalleled design freedom: SLM builds objects layer by layer directly from 3D CAD data. This allows the reproduction of complex geometries, honeycomb structures, relief patterns and fluid shapes found on many torches exactlyeven if the scale is significantly reduced. Functionality that could not be machined or cast becomes achievable.

- Material Authenticity and Strength: SLM 3D printers use metal powders such as aluminum alloys, stainless steel, titanium, and even gold alloys. This means that the mini flashlight is more than just a plastic toy; It’s a sturdy, permanent miniature made from real metal that more faithfully replicates the look and feel of its full-size counterpart.

- Rapid prototyping and production: Need quick prototype design approval? Want a small batch of custom torches ready for an event? SLM printing significantly reduces lead times compared to traditional molding and manufacturing. Iterate faster and cost less.

- Mass customization: Want to personalize each micro flashlight with a unique number, name, engraving or subtle design changes? 3D printing makes this approach economically feasible, even for single pieces.

Precision Engineering: How GreatLight Makes Mini Flashlights a Reality

As a leading professional rapid prototyping manufacturer, GreatLight specializes in transforming challenging concepts into tangible, high-precision realities. we use State-of-the-art SLM 3D printing technology Producing mini Olympic torches and countless other demanding applications.

Our process:

- Digital design: We use your concept (or adapt scan data from an existing torch) to create or refine a waterproof, printable 3D model optimized for SLM.

- SLM printing: Our advanced SLM printers use high-power lasers to selectively fuse layers of ultra-fine metal powders. This allows the mini-flashlight to be built precisely layer by layer, capturing every intricate detail defined in the CAD model with exceptional dimensional accuracy.

- Post-processing expertise – a one-stop solution: This is where GreatLight really shines. Metal parts coming off the printer require finishing. Our comprehensive in-house organization services include:

- move: Carefully remove the part from the build platform.

- Support removal: Precise removal of temporary support structures.

- Surface polishing/smoothing: Achieve mirror polish or specific textures (e.g. sandblasted, barrel polished, polished).

- Heat treatment (optional): Optimize material properties to increase strength.

- Engraving/Finishing: Add unique details, logos or textures. include plating! We can coat the 3D printed metal core with beautiful gold, silver, bronze or nickel finishes to achieve stunning visual effects and mimic the precious metals used in the actual Olympic torch.

- quality assurance: Rigorous inspection ensures each micro flashlight meets precise specifications and aesthetic standards before delivery.

Why partner with GreatLight to produce your mini flashlights (and more)?

- Advanced SLM technology: Gain high-quality metal additive manufacturing capabilities.

- Material Versatility: A variety of metals, including aluminum, stainless steel, titanium, tool steel and alloys such as Inconel, allow for true weight, feel and appearance customization.

- Complete in-house solution: From file optimization to final high-end finishing (including electroplating) – seamless, efficient and quality-controlled.

- Quick turnaround: Possess expertise in accelerating prototyping and low to medium volume production runs.

- Precision craftsmanship: A commitment to dimensional accuracy and surface perfection is paramount for these detailed reproductions.

- Problem solving: Ability to handle complex geometries and provide solutions that overcome the limitations of other manufacturing methods.

Huileite is more than just a supplier; We are your partner, bringing innovative, challenging miniature creations like the Olympic torch to life with technical excellence and a keen eye for detail. We are committed to solving complex rapid prototyping problems efficiently and professionally.

in conclusion

The miniature 3D printed Olympic torch represents a fascinating fusion of ancient ritual, modern design and revolutionary manufacturing technology. Metal 3D printing, and SLM in particular, opens up the possibility of creating high-fidelity, durable and mesmerizing replicas that were previously impractical or impossible. They are powerful symbols, beautiful collectibles, and testament to human ingenuity and technological advancement.

For businesses, designers, or organizations that want to create these miniature icons or any complex metal part, it’s critical to work with an expert like GreatLight. Combining advanced SLM hardware with comprehensive engineering expertise and state-of-the-art finishing capabilities ensures that the final product is not just a miniature torch, but a precision-manufactured masterpiece worthy of the Olympic spirit itself. Embrace the future of manufacturing and ignite your vision.

Frequently Asked Questions (FAQ) about the Mini 3D Printed Olympic Torch

Q1: Can a mini 3D printed flashlight really light a flame?

A: Typically, mini replicas are designed for display and collection, not for actual burning. While the metal itself is heat-resistant, integrating a safe and fully functional fuel system at a microscale is extremely challenging. They serve primarily symbolic and aesthetic purposes.

Question 2: What metals are best for these mini flashlights?

A: The choice depends on the desired look, feel and budget:

- Aluminum alloy: Lightweight, affordable, and easily polished or anodized in a variety of colors, perfect for intricate details.

- Stainless steel: Strong, durable, with premium weight and feel, perfect for plating. Often very popular.

- titanium: Extremely strong and lightweight, unique matte gray/silver finish, excellent biocompatibility. The cost is higher.

- Gold/silver plating: Painted over a base metal such as brass or steel, it creates an authentic, luxurious aesthetic that mimics an actual ceremonial torch.

Q3: How precise can a mini 3D printed flashlight be?

A: With high-resolution SLM technology, stunning details can be achieved. Features such as the complex grid structure, detailed engravings, symbolic patterns and smooth curves found on the real Olympic torch can be faithfully replicated down to a fraction of a millimeter. The limiting factors are usually the original design and selected printing parameters.

Q4: How long does it take to produce one?

A: Turnaround times vary based on design complexity, post-processing required (especially complex polishing or plating) and order volume. Expect 7 to 21 days for a finished, polished microtorch, possibly less for an unpolished prototype. GreatLight excels at optimizing for fast output.

Q5: How much does a customized mini 3D printed flashlight cost?

A: Cost depends largely on the following factors:

- Size and complexity: Larger/more complex designs use more materials and printing time.

- Material selection: Titanium is more expensive than aluminum; plating adds to the cost.

- Post-processing level: High polish or complex plating can significantly impact costs.

- quantity: Unit costs for bulk orders are significantly reduced.

Obtaining a specific quote requires detailing your specific requirements.

Q6: Why should I choose a professional service like GreatLight instead of a cheaper online 3D printing shop?

A: For a premium product like the Olympic Torch Replica, quality and functionality are paramount. Professional manufacturers like GreatLight offer:

- Advanced (SLM) Technology: Essential for high-detail metal parts.

- Materials expertise: Proper handling and finishing for optimal strength and finish.

- Post-integration processing: Seamless high quality finishing, including electroplatingunder one roof.

- Engineering support: Expertise to ensure manufacturability, optimized design and guaranteed quality.

- Consistency and reliability: Strict quality control and proven processes.

Cheaper shops often lack SLM capabilities, metals expertise, or adequate finishing options, resulting in sub-par results for complex metal replicas.

Q7: Can I provide a scan of an existing torch for reproduction?

Answer: Yes! GreatLight often works from 3D scan data of existing objects. This data needs to be processed carefully to ensure it is "water proof," Printable, suitable for SLM. We have the expertise to handle this conversion and potentially improve the model for optimal printing and miniaturization.

Q8: Does Huileite only produce Olympic torches?

Answer: Absolutely not! While the Mini Olympic Torch perfectly showcases our capabilities, our core expertise lies in Professional rapid prototyping and small to medium-volume production of complex, high-precision metal parts Across industries such as aerospace, automotive, medical devices, robotics, industrial machinery and consumer electronics. This torch is just one exciting application for our advanced SLM manufacturing and finishing services.