As a Star Wars fan, have you ever dreamed of having your own X-wing fighter fleet? While we may not be able to create life-sized replicas of these iconic ships, advances in 3D printing technology have made it possible to create an almost impressive mini X-wing fleet. In this article, we will explore the world of 3D printing and how to use it to create complex and detailed microscopes, including X-wing fighters.

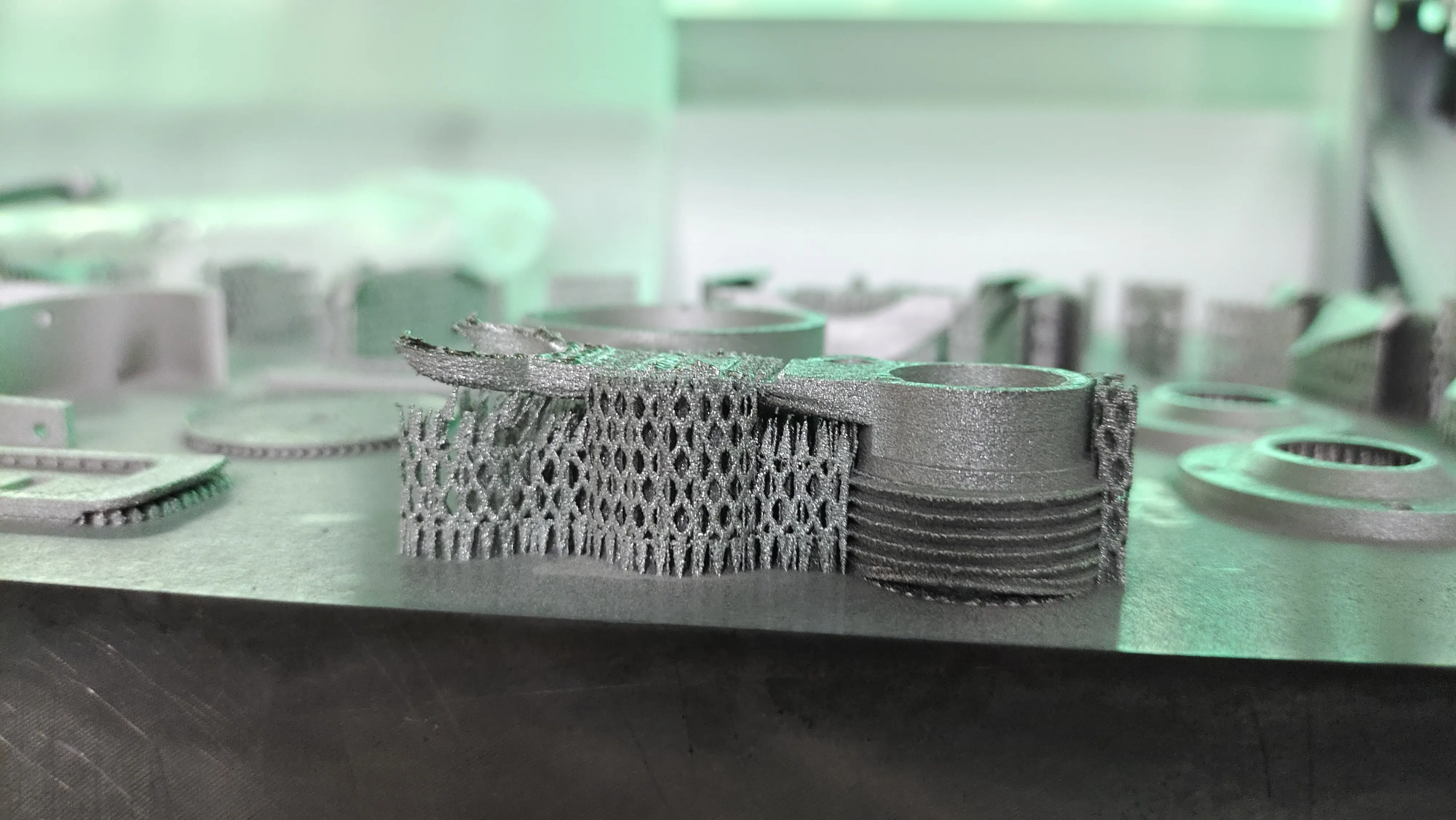

With professional rapid prototyping manufacturers, such as Greatlime, it is now easy to create complex metal parts. Greatlight’s Advanced SLM 3D printer equipment and production technology can create highly detailed and accurate microscopes, including those with complex designs such as X-wings. Their one-stop post-processing and completion services also ensure the highest quality of the final product.

One of the main benefits of 3D printing is its ability to produce custom parts quickly. This means that enthusiasts can easily create their own unique X-wing designs, and even create entire fleets. Whether you are an experienced collector or just starting out, 3D printing offers some customization and flexibility that is hard to find elsewhere.

In addition to its applications in creating mini X-wing fleets, 3D printing is also used in a variety of other industries, from aerospace to healthcare. Its ability to produce complex parts and prototypes quickly makes it an important tool for many businesses and organizations.

But how is the process of creating a mini X-wing fleet using 3D printed works? The first step is to use special software to design the X-Wing model. This can be done from scratch or it can be used with a pre-existing design as a starting point. Once the design is complete, it will be sent to a 3D printer that uses a combination of metal powder and binding agent to create complex details and structures of the X-wing.

The final product is then post-processed and completed to create a highly detailed and accurate miniature. This may involve a range of techniques, including polishing, painting and applying decals. The end result is a miniature X-wing that is almost indistinguishable from the real thing.

In short, creating a mini X-wing fleet using 3D printing is a fast-growing area of interest that is available in both hobbies and professional worlds. With the help of companies like Greatlight, it is now possible to create highly detailed and accurate microscopes, including those with complex designs such as X-wings. Whether you are an experienced collector or just starting out, 3D printing offers some customization and flexibility that is hard to find elsewhere.

FAQ

Q: What is 3D printing and how does it work?

Answer: 3D printing is the process of creating physical objects through digital design. It works by layering materials such as metal powders and bonding agents to create the desired shapes and structures.

Q: Can I create my own X-wing design using 3D printing?

A: Yes, with dedicated software and 3D printers, you can create your own unique X-wing design.

Q: Which material can be used for 3D printing?

A: A variety of materials can be used for 3D printing, including metal powders, plastics and resins.

Q: How long does it take to create a mini X-wing fleet using 3D printing?

A: The time it takes to create a mini X-wing fleet using 3D printing may vary depending on the complexity of the design and the number of units generated. However, with the help of professional rapid prototype manufacturers, such as Greatlime, high-quality miniatures can be produced quickly.

Q: Can I customize the post-processing and completion of the Mini X-Wing Fleet?

A: Yes, with the help of a company like Greatlime, you can customize the post-processing and completion of the mini X-wing fleet to create a unique and highly detailed final product.