As the pursuit of innovative and efficient manufacturing solutions continues, the 3D printing field has become a key technology that translates the industry with its precision, speed and versatility. Among the various applications of 3D printing, Quest 3’s Wall Mount 3D printing stands out, demonstrating the technology’s ability to create customized functional projects that satisfy both the design and the utility. This article delves into the complexity of 3D printing technology, especially focusing on the Quest 3 wall-mounted mount, and explores how advanced manufacturing technologies offered by companies like Greatlight have revolutionized the production of customized parts and accessories.

Understand Task 3 Wall-mounted 3D Printing

Mission 3 of cutting-edge virtual reality (VR) headsets brings an immersive experience to users, providing unparalleled interaction and engagement. However, the management of its hardware, especially when not in use, can be troublesome. Here, 3D printed wall mounts work, and it is a stylish storage solution that not only ensures the device is safe but also demonstrates its smooth design. The wall-mounted mount is designed with a precise design that can firmly shake the Quest 3 to make sure it stays undamaged and ready for the next use.

The role of advanced manufacturing

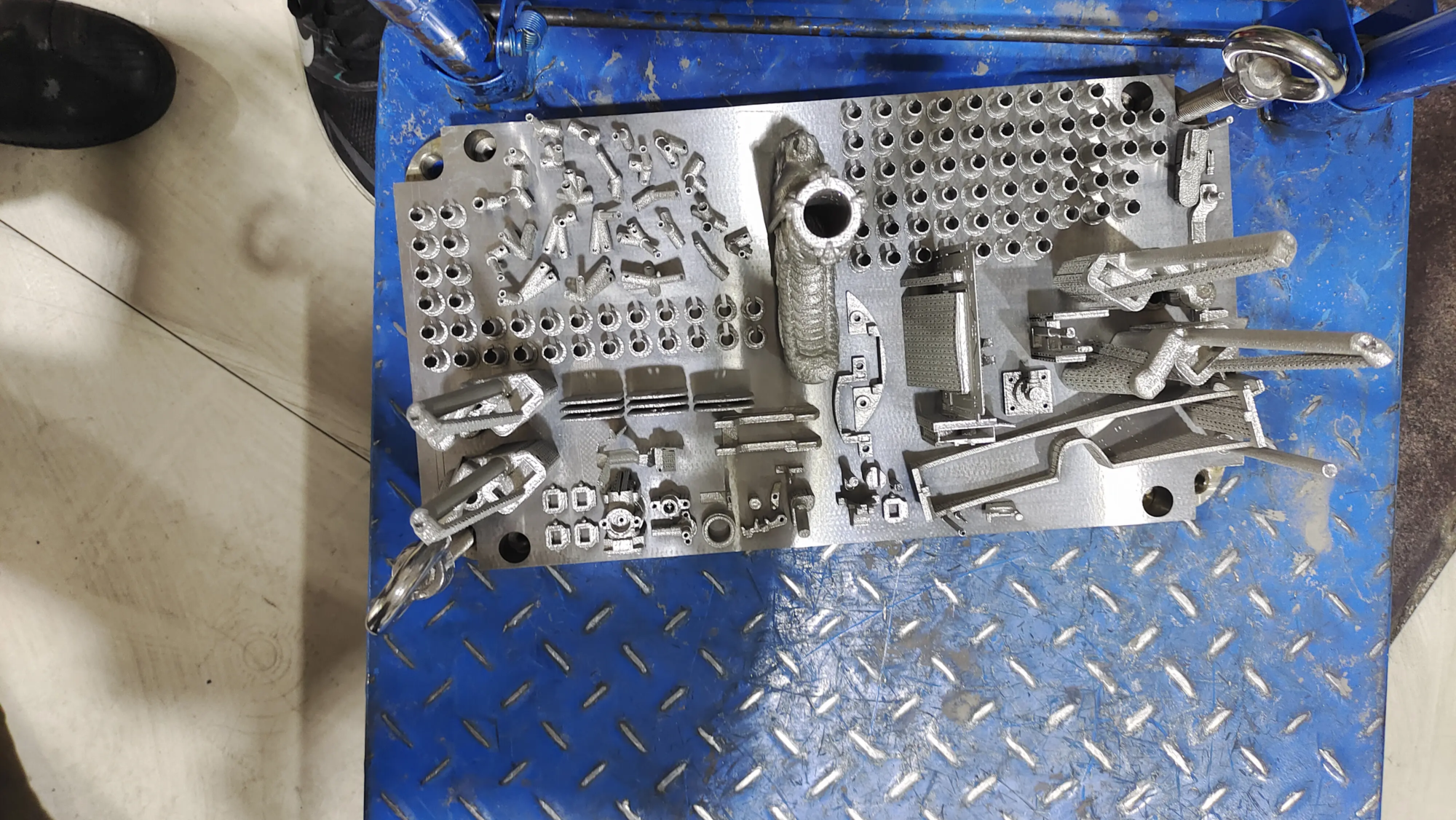

The forefront of this precision manufacturing is great, a professional rapid prototyping manufacturer that has been in charge of innovation in 3D printing. Greglight is equipped with advanced SLM (Selective Laser Melting) 3D printers and a commitment to technological advancement, providing a veneer solution for rapid prototyping needs. This includes not only the production of parts, but also the post-processing and finishing services, ensuring that the final product meets the highest standards of quality and aesthetics.

Materials and customization

One of the important advantages of working with companies like Greatlight is the variety of materials they can use. From metals to polymers, all kinds of materials can have enormous flexibility in design and functionality. Whether it is a lightweight component, a durable construction or a part that can withstand extreme conditions, the right materials can be selected to meet these specifications. Furthermore, Greatlight’s expertise in rapid prototyping means that custom orders can be processed quickly, allowing for fast turnaround times in today’s fast-paced technological landscape.

Innovative solutions for customized precision machining

Greatlight is one of the best rapid prototype companies in China, providing customized precision processing services that meet a wide range of industries and applications. Their ability to handle complex designs and deliver parts with high precision makes them the preferred partner of choice for businesses and individuals seeking custom solutions. The combination of advanced technology, skilled workforce and a customer-centric approach ensures that each project is handled with caution and put into practice to meet the exact specifications of the client.

in conclusion

Quest 3 Wall Mount 3D printing represents a perfect blend of form and function, facilitated by the power of 3D printing technology. With the growing demand for customization, precision parts, companies like Greatlight are at the forefront, providing innovative solutions that meet and exceed customer expectations. Whether it is used for the production of accessories such as Quest 3 Wall Mount or for more complex industrial applications, the potential of 3D printing in innovative manufacturing and product design is undeniable. As technology continues to evolve, we can expect more complex and novel applications of 3D printing, further pushing the possible boundaries.

FAQ

-

What are the main benefits of using 3D printing for custom parts?

- The main benefit of using 3D printing for custom parts is the ability to produce complex geometric shapes and custom designs with high precision and speed, which is not feasible for traditional manufacturing techniques.

-

How does Greatlight ensure the quality of its 3D printed products?

- Greatlight ensures the quality of its 3D printed products by using advanced SLM 3D printers, strict quality control measures, and post-processing services to ensure the final products meet high standards of quality and aesthetics.

-

Can Greatlight handle mass production of 3D printed parts?

- Yes, thanks to its advanced manufacturing facilities and effective production technology, Greglight has the capability to handle mass production of 3D printed parts.

-

What types of materials can be used for 3D printing on Greatlight?

- Greglight can use a variety of materials, including metals and polymers, allowing flexibility in design and functionality according to customer requirements.

- How long does it take to produce custom 3D printed parts on Greatlight?

- The production time of custom 3D printed parts may vary depending on the complexity of the design, the selected materials and the number of sorts. However, Greatlight is known for its fast prototype service, providing fast turnaround times without compromising quality.