Taming Trouble: Revolutionary Cable Management with Custom 3D Printing Sockets

Facing reality, our desks, entertainment centers and workspaces are the battlefield. Not against the enemy, but against the relentless thrust of the cables – charging ropes, power bricks, HDMI snakes, USB tendrils – all conspired to create a confusing, incredible, potentially dangerous chaos. Traditional solutions, such as universal plastic clips, Velcro tie or bulky cable boxes, usually fall off. They may be temporarily surround chaos, but rarely address the root cause: the socket itself becomes the center of chaos.

Enter a game-changing combination Neat sockets and 3D printing. It’s not just hidden wires; it’s about fundamentally reimagining and optimizing unparalleled connection points for unrivaled order and functionality.

Why traditional sockets fail us

Standard power strips and sockets are designed for functionality rather than form or advanced management. Consider it:

- Limited port locations: Usually the ports are gathered too close together to prevent adjacent plugs when using larger adapters. The vertical socket collides with the plug below; in the Tetris game we never want to play, the horizontal people become pawns.

- One size does not fit: They have fixed sizes and port counts, rarely exactly matching a specific number or type in a given location.

- Lack of comprehensive management: The minimum reserve for cable routing, strain or safety anchoring is accidental overflow of cables.

- Aesthetics are plain: While functionality is primary, visual confusion can increase stress. Standard sockets have little aesthetic customization.

3D Printing Revolution: Perfect Making, Port Port

This is where additive manufacturing or 3D printing is the ultimate problem solver. By designing and 3D printing custom sockets, we unlock new levels of cable management:

-

High quantification:

- Port count and type: Precisely need space for 3 USB-C ports, 2 standard AC sockets and large laptop charger? knew. No more need to waste ports or messy daisy chain power strips.

- Port spacing and direction: Design a port with spacious spacing, vertical/horizontal termination settings, or a 90-degree directional USB port to prevent bulky plug interference. Gone for a few days "Insert block A socket B."

- Device-specific cutouts: Combine together a niche of the perfect shape of a specific electric brick or equipment dock, securely securely and eliminate its awkward bulges.

-

Integrated cable management functions:

- Built-in channels and guides: Seamlessly route cables directly from the plug from the furniture (table grommet, drawer cavity) or wall/table organizer along hidden paths in the furniture.

- Strain relief hooks and clips: Stick small hooks, loops or small chops directly to the socket body to gently anchor the cable and prevent accidental tugs from breaking or pressure ports.

- Hide options: Build a shroud, hood or cover to partially or completely hide the plug while keeping easy access and airflow for cooling.

-

Enhanced functionality and security:

- Physical anchor: A sturdy mount is designed to securely attach the socket to the legs of the table, the walls, the bottom of the table, or inside the cabinet, thus preventing it from sliding or tilting.

- Ergonomic considerations: Location ports, easily accessible according to your specific settings. No longer awkward twists to insert things.

- ventilation: Strategy placement of ventilation holes and space components to properly ensure effective heat dissipation of any power brick or transformer is a key safety consideration.

- Aesthetic Harmony:

- The table follows the space: Handmade sockets that meet the exact size required for unique furniture cutouts or specific locations.

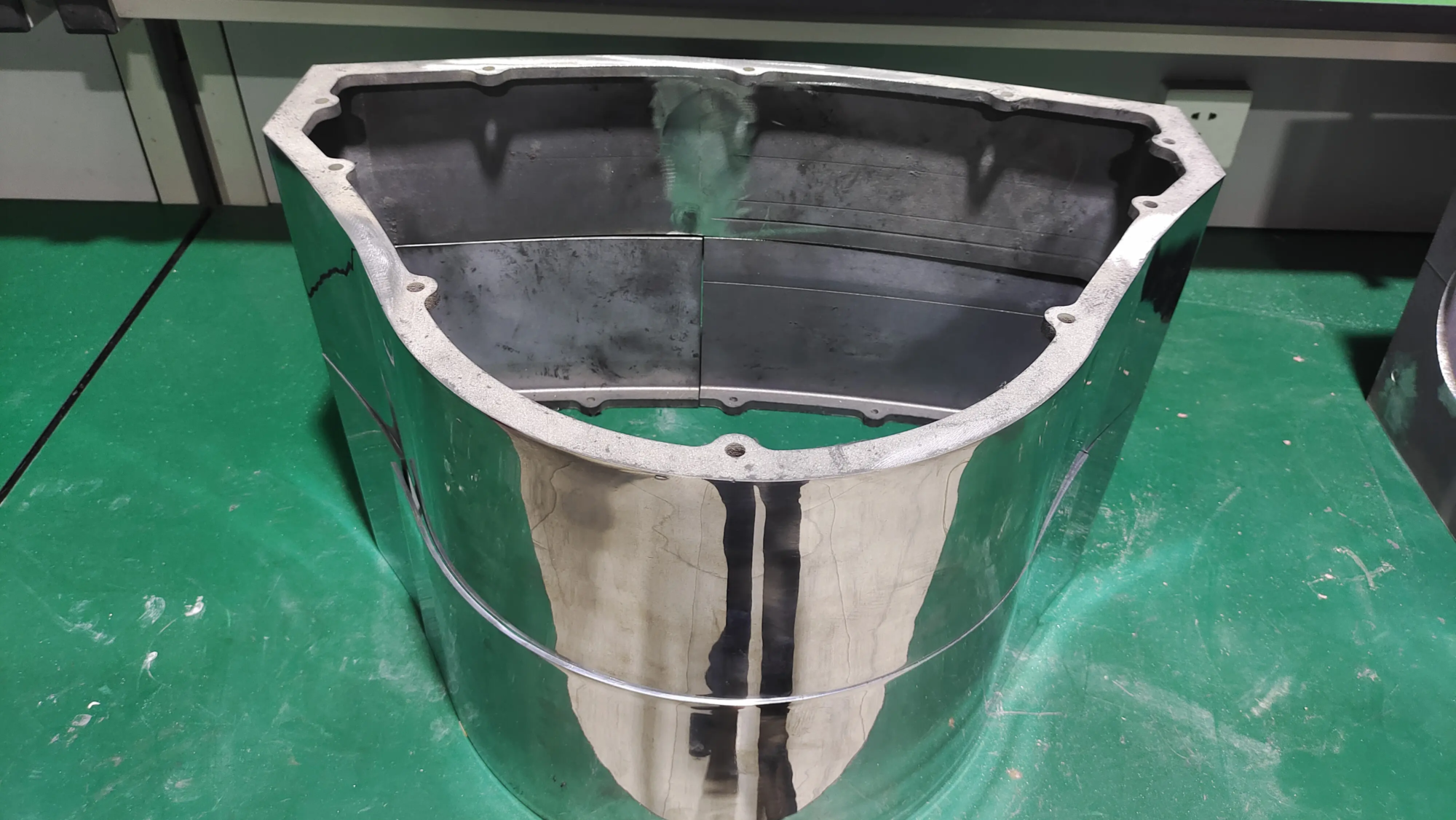

- Materials and Finished Selection: Although plastic polymers (such as nylon or ABS) are common for alkaline structures, We enter a realm of what we really do: advanced metal printing. Imagine a partial socket printed with lightweight aluminum or titanium near the transformer, embedded screw mounts for final strength, or just for unique quality aesthetics. Our Advanced SLM (Selective Laser Melting) Technology allows us to seamlessly integrate these high-performance metals into complex sleeve designs without the need for complex tools. Post-processing (such as sandblasting, removing powder and even anodized colors) further enhances the aesthetic and feel.

- Color Match: Perfectly match your office decoration, equipment color or company brand.

Introduction to Greatlime: Your partner is in a custom 3D printed neat socket

Concept is one thing; turning that concept into a powerful, functional, safe and beautiful reality requires expertise and the right technology. This is Great Raise yourself outside of a typical rapid prototype store.

-

Unrivaled metal printing capability: Our Arsenal includes the most advanced SLM 3D Printerput us at the forefront of metal additive manufacturing. Why is this important for sockets?

- Strength and durability: Metal slices (aluminum alloy, titanium, stainless steel) provide unparalleled structural integrity for installation points, hinges or areas under high stresses.

- Heat dissipation: Metal components will naturally stay away from basic power handling parts, enhancing safety and life – it is crucial to get close to an integrated AC socket or transformer.

- Professional integration: Create sturdy anchors, bus poles (designed by qualified engineers of safety regulations) and print directly to the part’s threaded inserts or quality end caps. SLM allows machining impossible complexity.

- High temperature stability: Metal parts can maintain integrity even when the components become warm, which is a key factor that limits space.

-

Safety and functional engineering expertise: We don’t just print shapes; we apply engineering principles. Designing an effective, safe electrical housing or compartment requires understanding the limitations. Our team ensures:

- Material suitability: Select electrically insulating plastics (eg, specific resins with UL grades where appropriate) and metals with favorable properties for the critical areas.

- Design adequacy: Ensure sufficient wall thickness, ventilation path and space between the conductive elements.

- Mechanical robustness: Design repeat plug/unplug cycles, cable strain and safe installation. notes: We do no Print active electrical components themselves.

- End-to-end solution: From design to perfection:

- Design consultation: Need help conceptualizing? Our engineers can turn your chaotic reality into elegant neat socket solutions.

- Precise manufacturing: SLM is used for complex metal parts required for structural elements or heat sinks. SLS, SLA and multi-jet fusion for precise, durable plastic housing and routing solutions.

- Comprehensive post-processing: Crucial to function and aesthetics:

- Metal: Sand/powder removal, heat treatment (pressure relief), CNC machining for critical interfaces, sand/media blasting, tumbling, polishing, anodizing (for aluminum – incredible color and corrosion resistance).

- plastic: Precise support removal, grinding (manual and tumbling), paint/coating, dyeing, assembly of multiple printing components.

- Safety Highlights: Thorough cleaning of metal parts, especially internal powder channels, is critical for electrical applications and life.

- Quick turnaround: Progressive time with our advanced machinery and streamlined processes – usually part of the product from design to shipment Only 48 hours Used for prototypes or small batches.

Conclusion: Turn chaos into calm

The battle with cable chaos is not necessarily endless. By embracing the power of customs 3D printed neat socketYou go beyond cosmetic repairs to create smart docking stations and built connection hubs Exactly Used for your equipment and space. This fusion of custom design and cutting-edge manufacturing – especially in including Powerful Metal Assembly Printed by SLM – Delivery:

- Unparalleled organization: Perfectly spaced ports, tailor-made fit and integrated cable routing.

- Space optimization: Eliminate wasted space and messy adaptations.

- Enhanced features: Easy to access, secure installation, better cooling (especially metal integration).

- Improve aesthetics: The socket becomes an integrated, cohesive element of your design.

- Rest assured: Professionally designed and manufactured durability and safety.

Stop wrestling with wires. Cooperate with it Greatleverage our expertise Accurate rapid prototypingadvanced 3D printing of metal (SLM) and plastic,meticulous Post-processing To create a perfectly tailored neat outlet solution, you end up bringing orders to your connected landscape. Transform frustration into elegant efficiency.

FAQ: Your neat socket and 3D printing questions have been answered

Q1: Can I print a power strip myself?

one: We strongly recommend that you print your own feature stripping. Safety and voltage are crucial. While Greglight can print custom housing and enclosures Power modules designed to safely hold commercially purchased and certified (For example, C13 socket, USB charging pad made by certified suppliers), we absolutely Do not print functional AC circuits, conductive tracks (such as bus poles without strict engineering and testing), plugs or sockets designed to handle voltages. Our role is to create a safe, customizable Infrastructure Certified electrical components around professionally manufactured. Safety compliance (e.g. UL, CE) is crucial.

Q2: Which material is best for 3D printing sockets?

A: It depends on the function of the part:

- Insulated main housing: Photopolymers by SLS/MJF, SLA/DLP (with appropriate thermal/intensity characteristics) or thermoplastics by FDM (nylon 12), photopolymers from SLA/DLP (with appropriate thermal/intensity characteristics). These provide electrical insulation and good mechanical properties.

- Structural frame, radiator, reinforcement: Metal! Aluminum alloy (lightweight, good heat dissipation), titanium (strong, high quality), stainless steel (durable) SLM Printing.

- Cable Guide/Clamp: The same plastic or flexible TPE/TPU with softer clips.

Q3: The durability of 3D printed sockets?

one: Extremely durable When correctly designed and manufactured. Engineering-grade thermoplastics (PA12, ASA) and metals (AL, TI) offer performance comparable to injection parts, especially during post-treatment. Key factors are design (proper wall thickness, support structure), material selection and professional manufacturing. Greatlime ensures that all components meet strict quality standards.

Question 4: Will metal parts interfere with electronic products?

A: Non-produced metals of aluminum and titanium (such as aluminum and titanium) do not interfere with the magnetism of typical consumer electronic signals. In fact, aluminum is often used in electronic housings. Our design process ensures proper use of metal components (e.g., for structural installation away from sensitive areas or dissipation of heat) and allows plastic to be insulated separately.

Q5: What is the price of a custom 3D printed neat socket?

Answer: The cost varies greatly:

- Size and Complexity: Larger sizes or complex designs require more material and printing time.

- Materials used: Metal components (especially through SLM) contribute more to costs than plastics.

- quantity: Unit cost decreases with larger batches, although sockets are usually unique or manufactured in small operating modes.

- Post-processing: Polishing, anodizing (metal), painting, etc. adds to the cost.

Contact with your specific concept or requirements for tailored quotes. Fast turnover and precision are at the heart of our value.

Question 6: What do you need to start with me to start?

A: It is very helpful to provide the following:

- Clear specifications: Number/type/size of the required port.

- constraint: It requires the size of the space that suits the fit (e.g., outdoor space, grommet hole size).

- Equipment diagram/picture: Shows any specific electric brick/wart/user interface that needs to be integrated.

- Aesthetic preferences: Color, finish, opacity.

- Functional requirements: Installation point, cable routing direction, need to reduce strain.

Our engineers can help develop designs when needed. For critical applications that require authentication components, detailed information about these components is critical.

Are you ready to abandon the cables in chaos? Greghime is here to design for your perfect, professional and neat solutions.