The essential guide to scrapers for 3D printers: The first line of defense for perfect prints

You have perfected the design, calibrated the printer, and selected high-quality wire. But as the printing ended, the excitement turned into frustration: the parts were fused to the build board. Enter the 3D Printer Tool Scraper – A seemingly simple tool that is crucial for successful printing. The right scraper is far from an afterthought, but protects your prints, protects your equipment and ensures easy post-processing. Let’s explore why this inconspicuous tool deserves the central stage in the workflow.

Why is bed scraper essential

3D prints to the build board with stability during printing. However, whether excessive adhesion is caused by PETG, textured surfaces, or imperfect levels can lead to damaged prints or scratching the bed. The scraper solves this and provides:

- Accurate removal: Safely lift the print without warping or rupture.

- Surface maintenance: Keep glass, PEI or textured bed free of scratches.

- Material versatility: Solve all problems from flexible TPUs to rigid metals.

Without one, you have the risk of using improvised tools to pry the print off and turn a tiny frustration into an expensive repair.

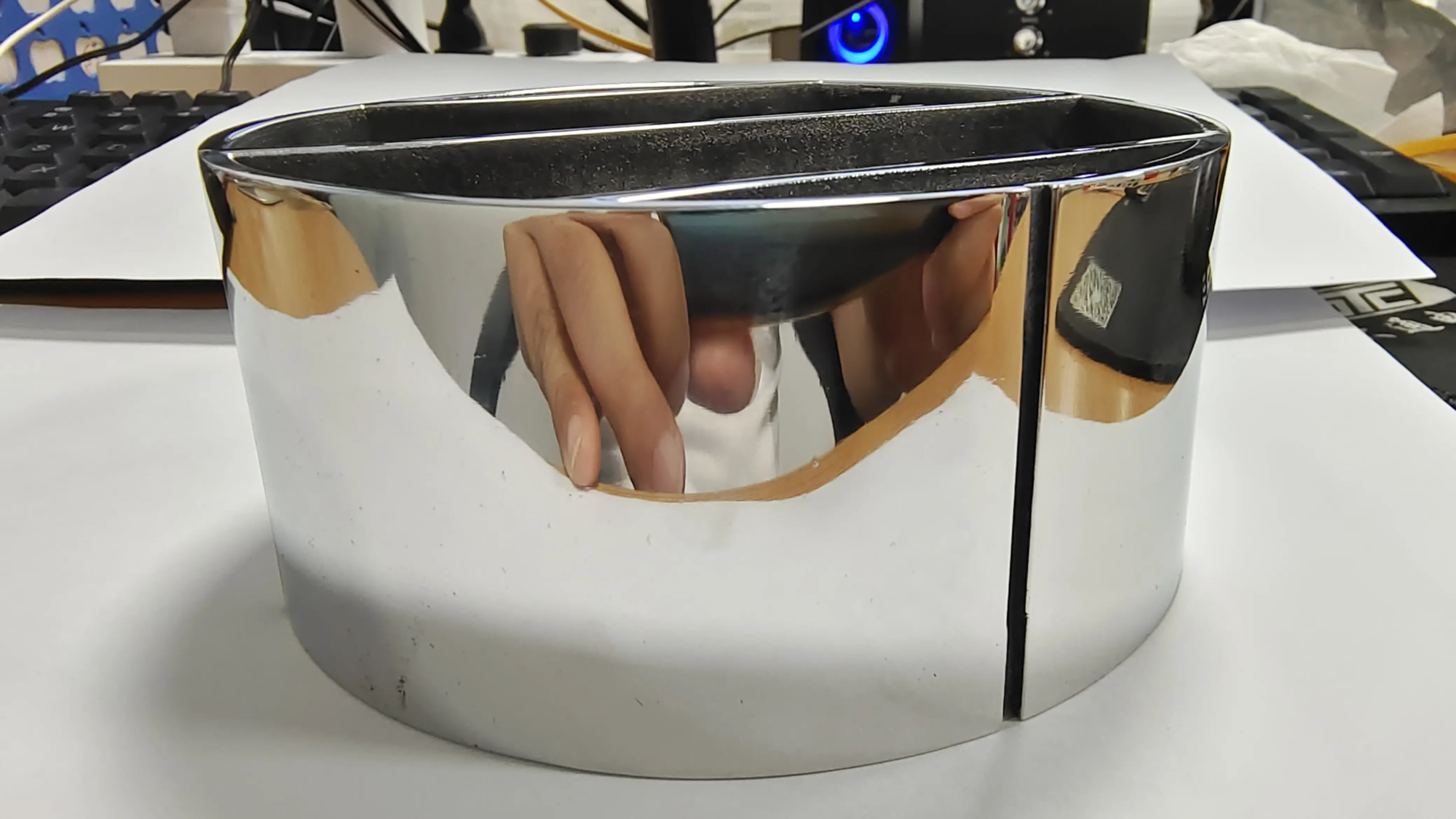

Anatomy of the perfect bed scraper

Not all scrapers are equal. Key features of priority:

1. Blade material and geometry

- Stainless steel: Ideal are stubborn materials such as ABS or nylon. Provides rigidity, but requires caution in softer beds.

- Hardened plastic: Best suitable for PEI or glass beds. Scratch is less likely, but may wear faster.

- Design nuances: Look for beveled edges (15°–30°) for controlled weightlifting and flat back for stability.

2. Ergonomic handle

Fatigue during large printing is real. Textured, non-slip grips reduce hand pressure, especially for large batches of work.

3. Strengthen connection

Avoid breaking the blade in the middle. Choose a model with a metal core that extends into a handle or molded grid design.

Metal and Plastic Scrapers: The Ultimate Showdown

| feature | Metal scraper | Plastic scraper |

|---|---|---|

| Durability | Highly durable and long-lasting | Easy to wear over time |

| Bed safety | Risk scratches on soft bed | Safe glass, PEI and Buildtak |

| Need strength | Less hard print efforts | Better fit for delicate parts |

| The best | Industrial materials, most | Amateurs often use PLA/PET |

For prompts: Use plastic for daily work and keep metal standby "Emergency" Disassemble.

Master scratching techniques to achieve perfect results

Step 1: Prepare

- Completely cool the bed (60°C → 25°C) to help print the contract.

- Apply isopropanol around the edges to weaken adhesion.

Step 2: Right Angle

- Place the scraper on a bed of 20°–45°.

- Tap gently: Use a small hammer (or handle end) Tap Blades around the corner – Never force it.

Step 3: Controlled Leverage

After insertion, rotate the tool down like a lever. Apply stable pressure leave From your body.

Avoid dangerous areas:

- Never pry yourself open: Sliding causes damage.

- No "chisel" vertical: Concentrated pressure crack printing.

Safety First: Protect you and your printer

- Wear anti-drug-resistant gloves: Cheap insurance for slips and falls.

- Preparation work area: No mess, always unplug the printer.

- Magnets be careful: Avoid using magnetic beds with metal tools – use only plastic.

Maintenance: Extend scraper life

- Clean after use: Use IPA to remove resin/debris.

- Sharpening blade: Harden steel scrapers every year.

- Check for burrs: Put down the scratches that can scratch the bed.

Retirement time:

- Chip or bending impairs blade integrity.

- Dealing with cracks can cause damage risk.

Conclusion: Improve your 3D printing game

A bed scraper is not only a tool, but also an investment in printing perfection. By choosing the right design, mastering low-impact technology and determining security, you can protect your creations and equipment. For professionals, this efficiency translates into faster turnover and reduced waste. With the development of additive manufacturing, such fundamentals are still unnegotiable.

FAQ: Answers to your bed scratch questions

Q1: Can I print my own plastic scraper?

Yes! PETG or ABS models are perfect for lightweight use. However, make sure the blade is evenly thin (2-3mm) and reinforced with internal geometry.

Q2: Why my scraper scratches "Anti-scratch" Glass bed?

Even hardened glass succumbs to metal tools. Use plastic scrapers specifically for coated surfaces.

Q3: What if printing doesn’t make people feel uneasy?

Apply 70% isopropanol around the edges and wait for 5 minutes. If it persists, Gently Heat the bed to 40°C – Thermal expansion helps break the keys.

Q4: Is putty knife feasible?

Avoid them. They are thicker, rounded edges lack precision and increase the risk of bed damage. Stick to the tools used for 3D printing.

Q5: How often should I replace the plastic scraper?

Check for blunt or microcracks of the blade every month. Replace every 6-12 months under heavy use.

Tired of the headache of removing printing? Focus on innovation, not scratching.

exist GreatWe combine industry-leading SLM 3D printing technology with unparalleled post-processing expertise. Farewell to bed adhesion battle – Our engineers make precision metal prototypes ready for final use. With ISO certified finishing (grinding, machining, heat treatment) and fast material customization, we transform complex designs into perfect parts for a few days.

Why fight with stubborn prints? Work with one of China’s top rapid prototype experts:

- ✅No scraper required – Parts are processed to your specifications.

- ✅Industrial metals: titanium, aluminum, stainless steel, etc.

- ✅Tolerance to ±0.05mm.

Contact Greglight now – Your vision is in line with our excellent manufacturing industry. Quote now and ship worldwide.