The Invisible Revolution: How 3D Printed Hairpins Redefine Fashion and Function

Mobile, mass-produced plastic clips. The engaging fusion of high-tech manufacturing and personal style is quietly changing the modest fashion accessory: hairpins. use Additive Manufacturing (AM)3D printed hairpins are becoming the next wave in customizable, durable and uniquely expressive accessories. They are not only a novelty, but also represent the practical application of industrial-grade technologies entering our daily lives, with unparalleled advantages over traditional methods.

Not only holding hair: The power of 3D printing

Traditional hairpins, while functional, are often limited: universal design, fragile construction, weight issues and transient trends. 3D printing breaks these constraints:

- High quantification: This is the jewel in the crown. Do you want a clip that is shaped like a pet’s outline with complex filaments initially, suitable for specific thick braided sizes, or ergonomic to maximize comfort? 3D printing makes it possible. The exact head profile that can be scanned for custom fits or transforms a unique artistic vision into wearable capabilities becomes possible. Personalized fashion has reached an unprecedented level.

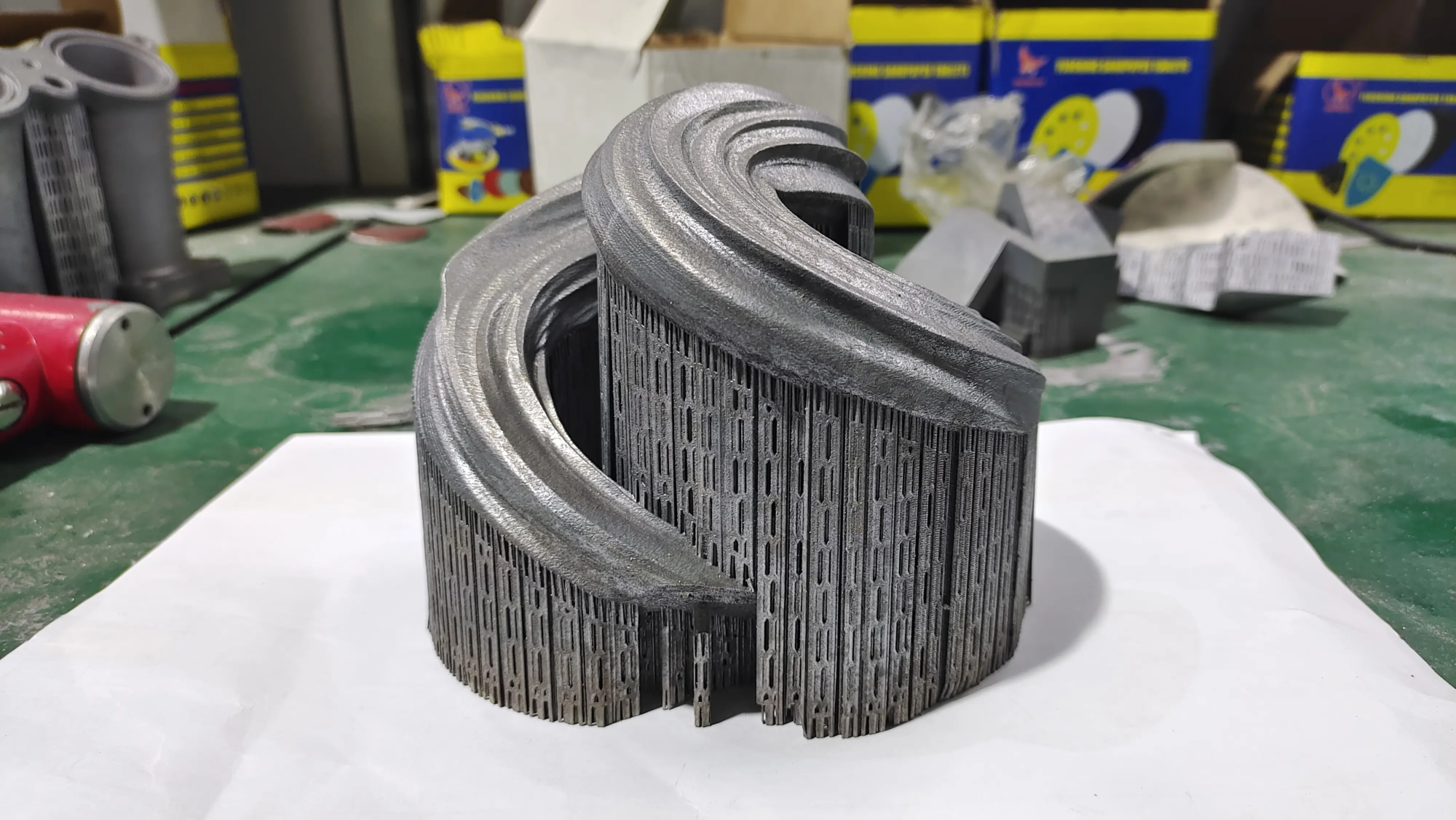

- No compromise complexity: Complex lace patterns, extreme weight-reducing honeycomb structure, dynamic interlocking mechanism, breathable design-AM is built layer by layer, creating injection molded geometry effortlessly that cannot be replicated. This unlocks the amazing aesthetic possibilities previously reserved for high fashion accessories.

- Unrivaled durability and lightweight design: Utilize advanced engineering materials (e.g. Nylon-based polymers (PA11, PA12), flexible TPUs and even high-performance metals When it comes to selective laser melting (SLM), 3D printed clips can be very powerful, but surprisingly lightweight. Imagine a big statement clip that feels feathers and doesn’t snap up after minimal use – that’s the advantage of AM. The complex internal lattice structure greatly reduces weight without sacrificing strength.

- Rapid prototype and iteration: For designers, the ability to go from concept to tangible prototypes in a matter of hours is revolutionary. Fast and affordable spring tension, button design or form factor tests in less expensive tools. This accelerates innovation and ensures final editing Really effective.

- Sustainable Potential (Fine Complete): Despite the differences in materials, AM is essentially less wasteful than the subtraction process. Use biocompatible or recyclable polymers (such as specific nylon or PLA derivatives) in combination with topical on-demand production to minimize building blocks, reduce transportation emissions, and allow for material selection consistent with environmental awareness, especially when planned strategically from the outset.

Alchemy of creation: From digital creativity to wearable art

The process is as fascinating as the result:

- Digital Engraving: It all starts with the 3D CAD model. Talented designers use professional software to digitally engrave each curve, hinge mechanism and decorative details. This file is a blueprint.

- Material and process selection: This design determines the materials and printing technology. Complex, durable plastic designs are often used Selective laser sintering (SLS)combined with laser nylon powder, has excellent strength and surface quality without support. For metal hairpins, seeking a unique high-strength feel (think luxury statement), Selective laser melting (SLM) It becomes a tool and fuses the metal powder layer with high accuracy. Flexible hinges may be used Multi-jet fusion (MJF) or a specific resin-based process (SLA/DLP) for detailed information. Advanced service providers have the expertise to guide this critical choice.

- Print: Layer by layer, accurately constructing materials based on digital models. Printing times vary, but happens faster than traditional manufacturing settings.

- Post-processing – Critical steps: Original prints usually need to be finished to become functional, safe and beautiful components or finished products. This can include:

- Support removal: Carefully detach from the temporary structure.

- Grinding and smoothing: Achieve the desired texture (matte, gloss) and touch.

- Media explosion: (especially for SLS/MJF/Nylon & Metals) Create a uniform matte finish or prepare the finish.

- dyeing: Inject vibrant and durable colors into nylon material.

- Vapor smoothing: For some plastics (such as MJF), this creates a sealed, glossy surface.

- coating: Add protective or decorative layers (such as biocompatible sealant or metal plating).

- assembly: Integrate springs, add cushioning or attach metal buckles/assemblies to plastic printing.

- Quality Control: Strict inspections ensure perfect functionality, smooth edges, safety compliance and compliance with the design.

Why Greatlight is your ideal partner for precision 3D printed hairpins and prototypes

Complexity of navigation materials, advanced printing technology SLM and SLS/MJFAnd achieving perfect post-processing requires deep expertise and industrial capabilities. This is Great shine. As a leading professional Rapid Prototyping Manufacturer With laser focus on accuracy, we solve complex manufacturing challenges every day and are perfect in bringing the visionary hairpin concept into reality.

- Advanced Industrial Equipment: We operate the most advanced SLM 3D Printer and other cutting-edge AM technologies such as high-precision SLS and MJF systems. This ensures the capabilities and choices required for the project, whether it is complex metal details through SLM or complex nylon structure through SLS/MJF.

- Material mastery: We don’t just print; we understand science. We offer a wide range of High-performance engineering polymer (nylon variant with different characteristics, flexible TPU) and Metal alloy Suitable for functional hairpin applications. We guide you to get the best materials for strength, flexibility, weight, biocompatibility and aesthetics.

- Seamless one-stop service: From initial design consultation and optimization to Accurate rapid prototyping Functional samples, Comprehensive post-processing and completionGreatlight can handle it all. Our expertise ensures that the editing is not only printed; it is perfect – smooth, dyed, complete professional standards, perfectly assembled. Consider complex geometric shapes perfected by precise machining techniques integrated into finishes.

- Speed meets accuracy: Will prototype iteration be needed tomorrow? Plan limited custom production runs? Our Rapid prototyping Core capabilities translate directly into faster turnaround times without sacrificing the meticulous accuracy required for exquisite accessories.

- Core customization: True customization is our profession. We not only adapt existing designs; we collaborate on creating your A unique perspective, leveraging our manufacturing agility to truly tailor-made to specifications, including precise integration of non-printed components when needed.

- Reliability and quality assurance: Trust is important. We are recognized One of the best rapid prototyping companies from Chinabuilt on Professionalism, technical expertise and a firm commitment to quality control. Your project benefits from strict standards established for your needs.

Conclusion: Remade individually designed styles

3D printed hairpins are more than just accessories. They are an embodiment of technological advances that align with artistic expression and personal identity. They provide liberation from universal design, empowering wearers and designers to create beautiful objects and are deeply aligned with individual taste and ergonomic needs. The combination of unlimited customization, structural innovation, surprising durability and unique sustainable potential makes them a compelling claim.

Ready to go beyond the limitations of traditional manufacturing and explore what is really possible? Whether you are a fashion designer pushing boundaries, looking for a brand that is unique product line, or individuals who want to ultimately personalize their accessories, Great supply Professional rapid prototyping Expertise and Advanced SLM 3D printing technology Implement it. We process precise and process complexes to Best Price.

Customize your vision. Experience huge differences. Request a quote from your 3D printed hairpin project now!

FAQ: Your answers to your 3D printed hairpin

-

Are 3D printed hairpins durable?

- Absolutely! When printing with appropriate engineering materials (nylon, specialty resin or metals such as stainless steel or titanium) such as SLS, MJF or SLM (such as SLS, MJF or SLM), they are very durable and elastic, often exceeding traditional plastic clips. Material selection and post-treatment are key factors for professionals, such as professionals.

-

Can I make a custom design?

- Yes, customization is the main advantage! From providing your own 3D models to collaborating on completely original designs, such as Greatlight Overlight, bringing unique visions to life. We can create custom shapes, incorporate names or logos, and make sure the clips meet your exact functional requirements.

-

Do they wear comfortable all day?

- certainly. Advanced printing allows for ergonomic designs that evenly distribute weight, internal lattice structures can greatly reduce weight without sacrificing strength, and use semi-rich materials such as TPUs to keep gentlemen. Perfect weight balance and avoiding stress points are design priorities.

-

What materials are usually used?

- plastic: Nylon (PA11/PA12) – Sturdy, durable, flexible and dyeable; TPU – Flexible, elastic (ideal for grip parts or soft parts); MJF machined plastics provide high detail and strength.

- Metal (via SLM): Stainless Steel (316L), Titanium, Aluminum – For high-end, ultra-durable, unique metal statement clips or critical components.

- Material selection depends on the aesthetic, strength, flexibility, weight and budget required. Greatlight provides expert guidance.

-

Are 3D printed hairpins environmentally friendly?

- Possible, and more and more. Compared to mass injection molding, AM greatly reduces waste and produces only the required waste. Use biocompatible or recyclable polymers (some nylon can be recycled) and topical on-demand production minimizes the carbon footprint. While energy use may be a factor, the overall life cycle impact may be low and sustainable practices are developing rapidly. We prioritize material efficiency.

-

Why choose a service like Greatlight instead of a Home 3D printer?

- Professional industrial printers (SLS, MJF, SLM) Provides great advantages Material properties (Strength, Durability, Biocompatibility), Surface finishand accurate Compared to the typical amateur FDM printer. Greatlight’s expertise ensures design optimization and access to a wide range of quality materials. Professional post-processing (smooth, dyed, plating) and strict Quality controlleading to safe, high-end, wearable products, not just prototypes.

- How do I start with Greatlight?

- Contact us directly! Share your concept, sketch or existing 3D files (if any). Our team of experts will consult with you on the feasibility of design. Material selection,,,,, Complete Optionsand Cost-effective solutions Customized to your vision body – whether it is a single unique piece or a production run. We specialize in transforming ideas into tangible precise components.