When it comes to unique and practical works of the house, few capture imagination like Octo Wine Holder. This innovative product is a perfect blend of design and functionality, making it a must-have for wine lovers and those who appreciate modern decor. But what makes Octo wine holders so special and how its creation connects to the world of rapid prototypes and advanced manufacturing technologies?

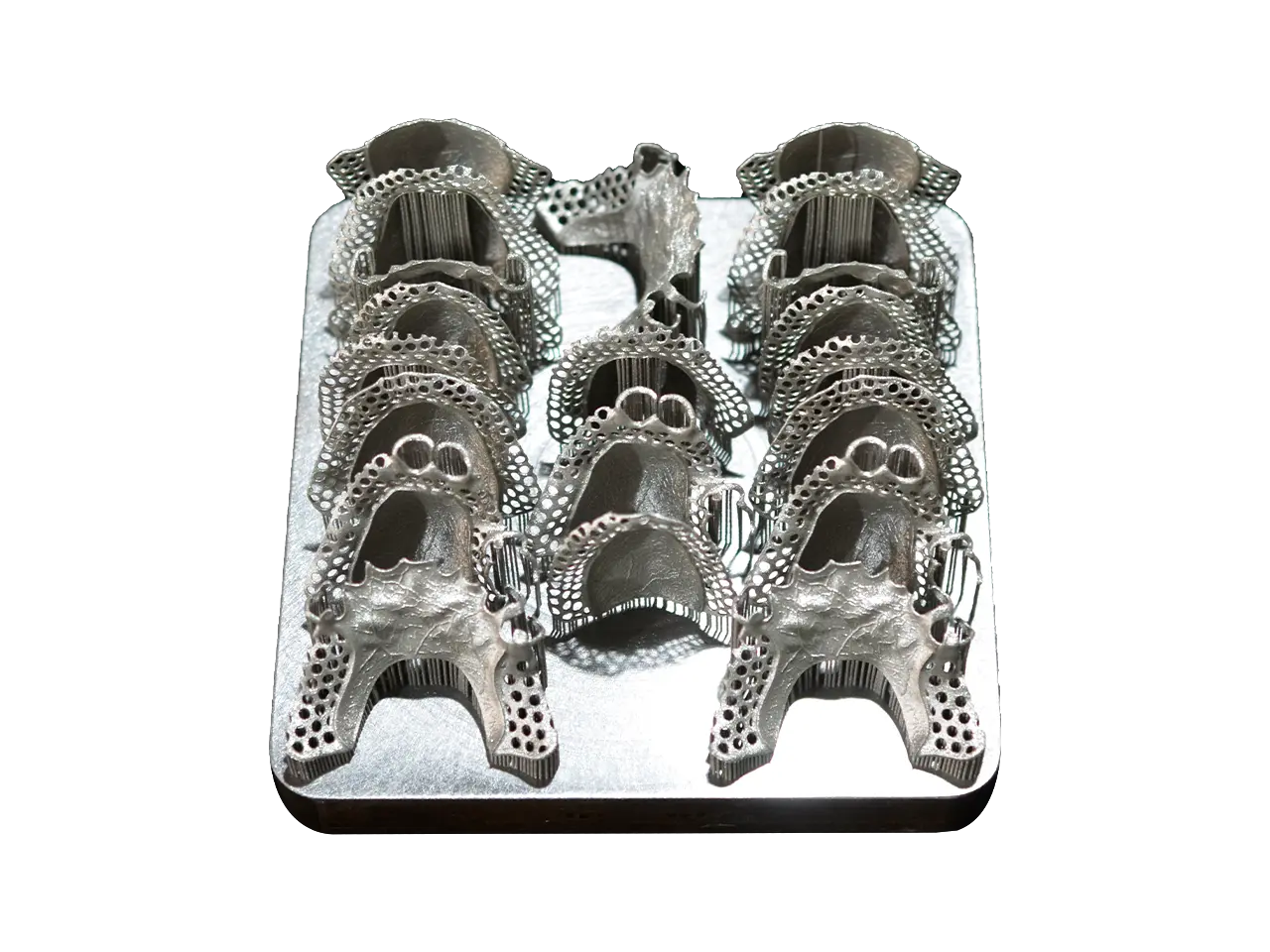

The core of Octo wine owners’ production is the use of advanced SLM (selective laser melting) 3D printing technology. This approach allows the creation of complex geometries that traditional manufacturing techniques will not be able to produce. Companies like Greatlight, a professional rapid prototyping manufacturer from China, specialize in solving metal parts manufacturing challenges using such technologies. With their cutting-edge SLM 3D printers and expertise in post-processing and finishing services, they can quickly customize and process materials, providing a one-stop solution for precise machining needs.

The design of Octo wine holders itself proves innovation and functionality. Its octopus-inspired shape not only adds a hint of whimsy to any room, but it also serves as an efficient way to store wine bottles. Each "tentacle" The holder’s meticulous design is designed to firmly shake the bottle, making it a practical solution for wine lovers who want to present their collections in a unique and visually appealing way.

From a manufacturing perspective, Octo wine holders’ creation highlights the ability and potential of rapid prototyping. By adopting advanced 3D printing technology, manufacturers can quickly go from design concepts to physical prototypes, greatly reducing development time and costs. This approach can also enable the production of complex designs through traditional manufacturing methods, thus breaking through possible boundaries in product design.

For those interested in custom precision machining or creating unique products such as Octo Wine holders, working with a professional fast prototype company can be a game-changer. With its advanced equipment and expertise, Greglight offers customized solutions that meet a wide range of needs from initial prototype development to final product manufacturing. Their commitment to quality, coupled with the speed and flexibility of rapid prototyping, makes them ideal for projects that require precision and innovation.

In short, Octo wine holders are more than just a novel way to store wine. It represents a fusion of design, functionality and advanced manufacturing technologies. The role of rapid prototyping in creation emphasizes the potential of this technology to revolutionize product design and production. Whether you are a wine lover, looking for unique ornaments or innovating with custom precision machining, the Octo Wine Holder story is a compelling example of what can be achieved at the intersection of creativity and cutting-edge technology.

FAQ

-

What is SLM 3D printing and how does it promote production of Octo wine holders?

- SLM (Selective Laser Melting) is a 3D printing technology that uses laser melting and fuses metal powder into solid parts. This approach allows the creation of complex structures and geometric shapes, making it ideal for producing complex designs such as Octo wine holders.

-

Can I customize Octo wine holders?

- Yes, with fast prototype manufacturers like Greatlime, you can customize the design of Octo Wine Bolder. They provide one-stop post-processing and completion services, allowing personalized adjustments to the final product.

-

What are the benefits of using rapid prototyping for custom precision machining?

- Benefits include reduced development time, the ability to create complex designs, cost savings, and the flexibility to make design changes quickly. Rapid Prototyping also enables rapid production of functional prototypes for testing, which can significantly improve the product development process.

-

How does Greatmight ensure the quality of its rapid prototype services?

- Greatlight ensures quality with its advanced SLM 3D printing equipment, production technology expertise, and a commitment to delivering one-stop post-processing and completion services. This comprehensive approach ensures that products like Octo Wine Holder meet high standards of quality and functionality.

- Can I order custom designs that are not relevant to wine holders?

- Yes, companies like Greatlight specialize in custom precision machining and can work with customers to develop and manufacture a wide range of custom parts and products. Their services are not limited to specific designs such as Octo wine holders, but they can meet a variety of needs in different industries.