Introduction: Challenges that Cause Overhang in 3D Printing

The boundaries of freedom of design are one of the biggest advantages of 3D printing. But even this transformative technology has its limitations, and one of the most common challenges designers and engineers face is Overhanging angle. Understanding what drapes are, why they cause problems and how to overcome them is essential for successful prints, especially in demanding areas such as industrial prototypes and end-use metal parts. As a leader in advanced metal additive manufacturing, Greatlight encounters and solves complex overhang challenges using state-of-the-art selective laser melting (SLM) technology every day. This article delves into the science and solutions surrounding the angle of drape.

What exactly is the dangling angle?

In 3D printing, when a part of the part extends outward, overhang occurs, and is not supported in the layer below it. this Overhanging angle is a key measure to decide whether the unsupported section can be successfully printed without sagging or crashing. Imagine building a structure built from bricks: if you try to place the bricks too far away from the edge of the upper layer, you may fall off. The function of 3D printing is similar, layer by layer.

- Define critical angle: This is the steepest angle the material can reliably print (relative to the build board) No Support structure. Angles are steeper than this threshold (i.e., closer to the level) become problematic.

- Physics behind the problem: Gravity is the main culprit. Since molten materials (plastic wire, resin or metal powder are laser melted) are deposited on the void, there is a lack of foundation for accurate curing. This leads to:

- Sagging/sagging: The material curls downwards before solidification.

- Collapse: Complete failure of not supporting part.

- Surface roughness: Uneven "Stair steps" Or the rough, harsh appearance of the bottom.

- Inaccurate dimensions: The final printing function deviates significantly from the digital model.

- Increased stress concentration (metal): In metal AM, well-managed overhangs can lead to thermal stress during rapid melting and cooling, resulting in porosity, warping or cracks when removed on the support.

Material Problems: Critical Angles vary

There is no single universal "Safe" Overhanging angle. This depends to a large extent on Printing technology and Material properties:

- Fusion deposition modeling (FDM-plastic):

- Typical critical angle: 45 degrees is a common suggestion, but the range of 30 to 60 degrees is set according to the polymer, cooling rate, layer height and extrusion settings. Bridge section (horizontal printing between There are also strict restrictions on both support.

- Stereo-lithography (SLA/DLP-resin):

- Typical critical angle: Due to the low viscosity of the resin during exposure, it is usually below FDM and sometimes as low as 30 degrees. Important overhangs almost always require support.

- Powder bed fusion (SLS, SLM-Plastic and Metal):

- Plastics (SLS): Since the surrounding uninserted powder acts as passive support, shallow overhangs (about 30-45 degrees) can be handled.

- Metal (SLM/DML): A steeper minimum angle (usually 45 degrees) is usually required to achieve true self-supporting features. Below this, supporting structure becomes crucial. The high melting point and thermal stress of metals make overhangs particularly challenging. Complex metal geometry at low angles is required to drive machine calibration, parameter adjustment and material science limitations. This is where Greatlight’s SLM expertise lies.

Conquer the Dang: A Success Strategy

Successful navigation of overhangs requires a combination of intelligent design, strategic printing selection and leverage advanced technologies:

Design optimization (first line):

- Self-supported perspective: Where feasible (~45+ degrees of metal), the target’s characteristics are steeper than the critical angle of your technique/material.

- Taper or chamfer: Gradually transition from the vertical wall to the horizontal surface instead of sharp corners (attack angle <90 degrees).

- Fillets and Radius: Adding curvature at the joint between the vertical wall and the overhanging surface can significantly improve its stiffness and printability.

- Hole and Channel: Where possible, the vertically directed non-functional hole. For horizontal holes or passages, consider teardrop shapes or diamond reinforcements to avoid the need for trapped support.

- Progressive overhang: Instead of a single length overhang, it is divided into shorter stepped sections.

Power to support structure:

- When the design is not enough: Supports are critical for the angles of long bridges and islands below the critical threshold (characteristics of floating in space). They provide necessary scaffolding during printing.

- Types and Challenges:

- Tree Support (FDM/SLA): Thin branch structures make easier to remove and smaller surface damage. Metals are less common.

- Block/linear support (SLA/metal): The denser grid-like structure provides strong support, but it is difficult to remove and leave more surface markings.

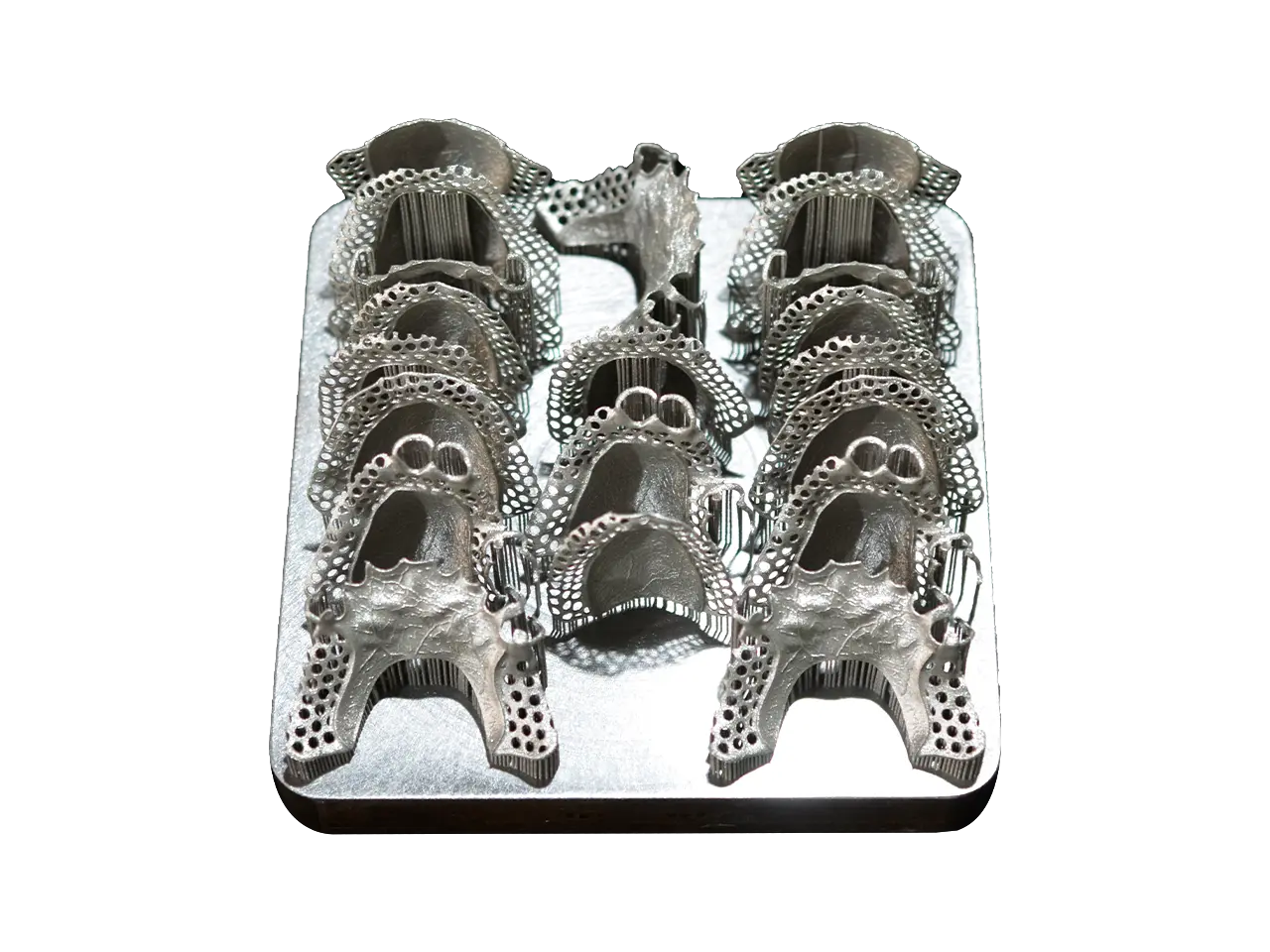

- Metal support is imperative: In metal SLM printing, proppant works much more than preventing collapse. They secure parts to the build board to resist warping and Acts as a critical radiator, driving excess heat away from the melt pool to prevent overheating defects in the overhanging area. GREATHIMETS’s well-designed engineers support structures, balance strength with removal of complexity and post-processing work.

- Printer setup and process control (especially important for metal):

- Optimal parts orientation: It is crucial to rotate the model to minimize the severity and number of overhanging surfaces. It usually takes trade-offs with build time or other partial requirements.

- Layer height: Thinner layers usually produce better overhanging surfaces, but increase build time.

- Cooling (FDM/SLA): An effective cooler/fan quickly hardens the deposited material on the overhang.

- Laser and Scanning Strategies (SLM): Greatlight optimizes precise parameters for dangling areas. This involves reducing laser power, adjusting scanning speed, changing scanning modes (e.g., contour scanning), and implementing a small, offset perimeter overview ("skin" Parameters) Create a more stable foundation for the dangling of subsequent layers. This requires in-depth process knowledge and machine calibration.

- Multi-axis printing (groundbreaking): Emerging systems can tilt the build board or laser head during printing, theoretically creating zero-angle overhangs without support. Still mainly in R&D/niche applications.

Greatlight’s SLM Advantages: Mastering Complex Overhangs in Metal Prototypes

Precision metal prototyping requires absolute control over challenging geometry such as steep overhangs. Greatlight leverages its advanced industrial SLM printers and profound process expertise to deliver:

- Expert parameter adjustment: Our engineers go beyond standard machine profiles. We carefully optimize laser power, scanning strategies, hatch spacing and layer management Specifically Danging function for unique parts. This can accurately reduce the required heat input, thereby minimizing residual stress and surface defects.

- Intelligent support engineering: We design effective support structures that provide the necessary thermal conductivity and mechanical anchoring without excessive material consumption or complexity. The focus is on manufacturing and easy to post-treat.

- Advanced Material Handling: Our ability to deal with a wide range of metal alloys, including challenging materials such as reactive alloys, allows us to select materials based on the inherent benefits of protruding structures based on characteristics such as thermal conductivity and curing behavior.

- Integration post-processing: Removing support from complex metal parts, especially deep inside channels or cavity is a critical challenge. Greglight provides comprehensive one-stop post-processing – CNC machining from precise wire movement to critical interfaces, aerospace-grade heat treatment, hip joints (thermal isometric pressing) for density and pressure relief and various surface finishing options. This ensures that the final section complies with the strict dimensional, surface and mechanical performance standards of our facilities. No need to coordinate multiple vendors.

- Design of Additive Manufacturing (DFAM) Consultation: Our team not only prints files; we work together. We proactively identify potential drape issues in your design during file analysis and provide expert DFAM advice to optimize manufacturability and performance forward Start printing and avoid cheap iterations.

Conclusion: Overhang – Solved Challenges with Expertise

Overhanging angles are inherent in fabrication by layer, but far from being insurmountable. High-quality results can be achieved by understanding the fundamental principles, leveraging design best practices, and strategically adopting supportive structural and process optimization. For metal components, especially complex prototype and end-use parts, there is a higher demand. Thermal management, support for design and post-processing are key success factors. Here, working with experienced rapid prototype providers like Greatlight (Greatlight) becomes invaluable.

Our investment in advanced SLM printers, proprietary process knowledge, meticulous parameter optimization and integrated post-processing capabilities ensures that even the most complex geometric shapes with obvious overhangs achieve the highest standards of accuracy, surface surface and material integrity. We transform the challenge of dangling into an opportunity to provide excellent precise metal parts.

Ready to meet your next complex prototype challenge? Greatlight provides technology and expertise to ensure that your design, no matter how innovative it is, becomes a reality with precision and reliability.

FAQs on Overhanging Angles in 3D Printing (FAQs)

Q1: What is the maximum overhang angle that I can print without support in a metal SLM?

A1: While the achievable angle depends to a large extent on the geometry, material, printer calibration and process parameters of a particular part, General Guide to Metal SLM is 45 degrees Relative to the build board. Angles less than 45 degrees usually require support structures for physical support and thermal management. Greatlight carefully analyzes each design to determine the optimal minimum angle and support strategy.

Q2: Can 3D printers print inverted or horizontally without support?

A2: Printing true horizontal overhangs (0 degree angle) without support structures is extremely challenging in almost any 3D printing process. The material has no adhesion underneath. Even with advanced technology in SLM, very low angles (<30 degrees) require engineering support to achieve reliable results. Design strategies such as teardrop holes or parallel gap avoidance are used for specific functions such as channels. Emerging multi-axis printers are designed to address this limitation.

Q3: Does support always leave traces or damage parts?

A3: Supporting interaction inevitably leaves some evidence. In FDM/SLA, the interface may leave a rough surface or require sanding. exist Metal SLM, strongly supported on the fusion on this part. Careful design minimizes contact area. With CNC machining, wire EDM or careful machining disassembly is part of the Greatlight standard post-processing workflow that smoothly cleans the surface.

Q4: Is the overhang larger than plastic in metal 3D printing?

A4: Usually, yes. Although overhanging poses a challenge in all technologies, metal SLMs present other difficulties:

- Higher melting temperatures lead to severe thermal gradients and stresses.

- The support volume is higher and the integration is stronger.

- Cancelling support is more complex and risky.

- Quality issues such as porosity or distortion directly affect critical mechanical properties. Therefore, expertise in metal process control is crucial.

Q5: How does Greatlight handle the removal of internal support structures in complex metal parts?

A5: The removal of internal support is very complicated. Gremight combines strategies:

- Simple design: Use a feasible lattice structure or disengagement point.

- Chemical etching: For some materials/geometric shapes.

- Precision machining: CNC milling to access the opening.

- Wire EDM (Electrical Emission Processing): Our expertise in tools and fixation allows us to accurately cut the internal support of the fusion from the depths of the inner cavity without damaging the main part – very few features have inside the prototype store.

- Ultrasonic/EDM drilling: For small deep channels.

Question 6: Can a separate software solve the drape problem?

A6: Software (slicer) is crucial to generate support structure and optimization direction, but They are tools, not complete solutions. Effective drape management requires:

- Human DFAM expertise: Critical explanation of software suggestions, modify upstream designs, and make subtle decisions on support strategies.

- Process knowledge: Learn how printer settings (especially laser parameters in SLM) affect overhang quality beyond what auto-generated support can achieve.

- Hardware calibration: A good machine is basic. Greatlight’s deep technical expertise bridges the gap between software automation and actual physical printing constraints.