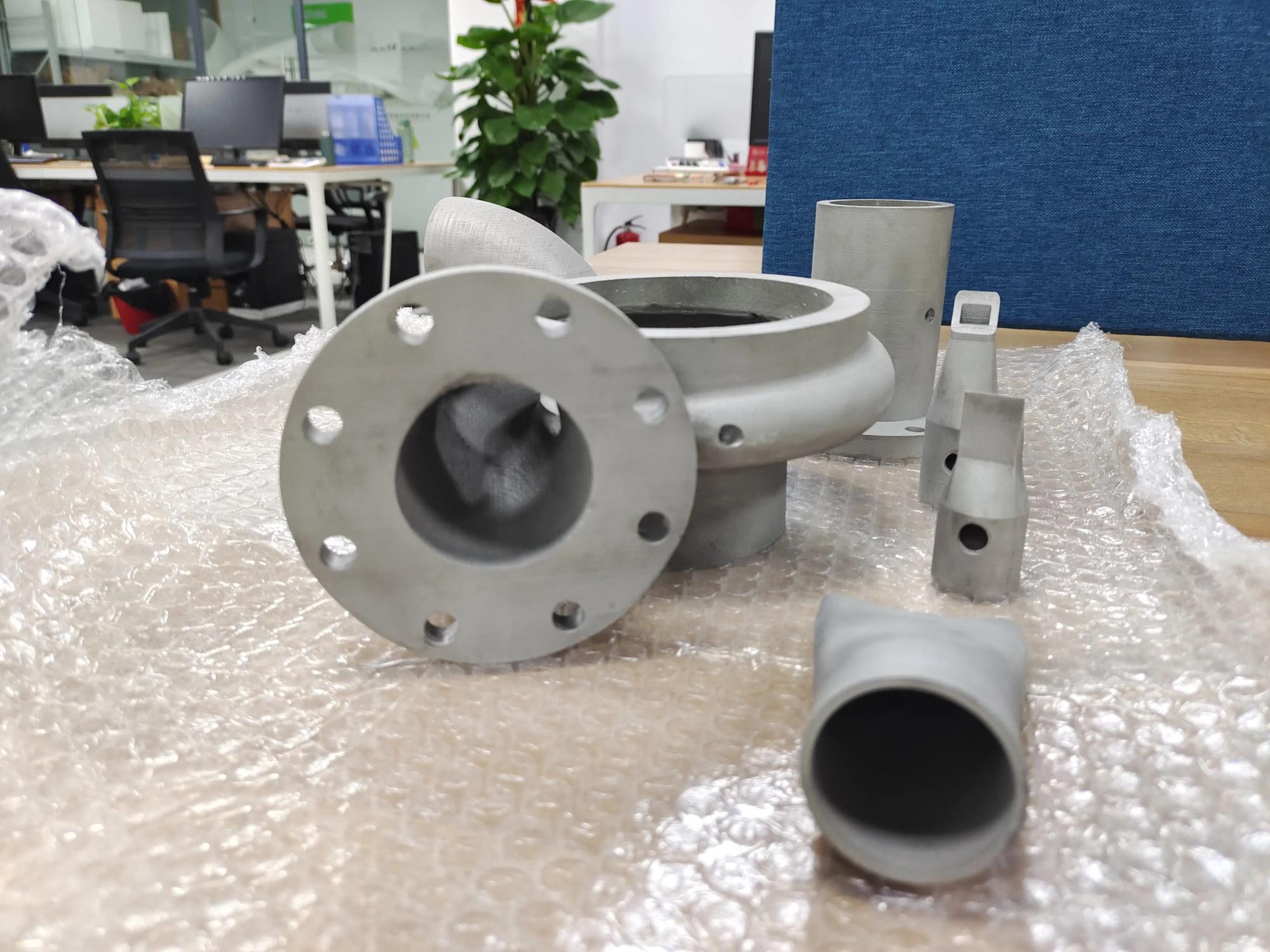

In the manufacturing field, pursuing perfection is a continuous pursuit. With the advent of advanced technology, companies are now able to achieve unprecedented accuracy and accuracy in their products. The technology that revolutionized the industry is 3D printing, especially selective laser melting (SLM) technology. Greglight is a well-known rapid prototyping manufacturer that has been at the forefront of this innovation, using SLM 3D printers to produce metal parts with unparalleled accuracy.

At Greatlight, the combination of cutting-edge equipment and refined production technology allows companies to address even the most complex metal parts rapid prototyping challenges. Their capabilities are beyond the scope of just production, as they also provide one-stop post-processing and completion services. This comprehensive approach ensures that customers receive their products under conditions of imminent use, saving time and resources. Furthermore, Greatlight’s flexibility in material customization can quickly process most materials, thus meeting the various needs of its customers.

Customization of precise prototyping parts is a great specialty dish, positioning them as one of the best rapid prototyping companies in China. Their expertise in precision machining, coupled with the commitment to delivering products at competitive prices, makes them an attractive choice for businesses seeking high quality, cost-effectiveness. By tailoring its services to meet the unique requirements of each customer, Greatlight promotes long-term partnerships based on trust and satisfaction.

The advantages of choosing Greatlime for 3D printing services are multifaceted. First, their advanced SLM 3D printers ensure that all products are manufactured with the highest accuracy and adhere to the strictest quality standards. Second, their one-stop service package (including post-processing and finishing) simplifies the production process, reduces lead time and improves overall efficiency. Finally, the ability to customize materials and parts to a specific need ensures that customers get products that exactly match their specifications, eliminating the need for expensive rework or adjustments.

There are several benefits to incorporating 3D printing technology (especially SLM) into the manufacturing process. It allows the creation of complex geometric shapes and structures that cannot be produced by traditional manufacturing methods. Furthermore, it reduces material waste and can lead to weight reduction in the final product, which is especially beneficial in industries such as aerospace and automotive. The accuracy and reliability of SLM 3D printing also makes it an attractive choice for medical implants and surgical instruments where accuracy is critical.

However, several factors need to be carefully considered in the successful integration of 3D printing into manufacturing. This includes selecting the appropriate materials, understanding the limitations and capabilities of the technology, and ensuring that the manufacturing process complies with relevant industry standards and regulations. With its expertise and experience, Gregmaind is well positioned to guide clients to carefully study these considerations and provide consulting services that complement their manufacturing capabilities.

All in all, Greatlight is an outstanding beacon in the field of rapid prototyping, leveraging the power of SLM 3D printing to deliver precise parts with unprecedented precision and speed. Their commitment to customization, quality and customer satisfaction positiones them as the primary option for businesses seeking to leverage the benefits of 3D printing. Whether it is the need for complex metal parts, precise machining or comprehensive post-processing services, Greatlight provides a one-stop solution that is both innovative and reliable.

FAQ:

-

What is a rapid prototype?

- Rapid prototyping refers to a set of techniques used to quickly manufacture physical parts or assemble scale models using 3D computer-aided design (CAD) data.

-

What is SLM 3D printing?

- Selective laser melting (SLM) is a 3D printing technology that uses high-power lasers to melt and fuse metal powders to create complex structures and parts layer by layer.

-

What materials can be used for SLM 3D printing?

- A variety of metals may be used, including aluminum, titanium, stainless steel, etc., depending on the specific requirements of the application.

-

What are the benefits of using Greatlime for 3D printing services?

- Greatlight offers precision, speed, customization and one-stop service, including post-processing and completion, all available at competitive prices.

-

How does Greatshile ensure the quality of its products?

- Greatlight uses advanced SLM 3D printing technology, strict quality control processes, and experienced professionals to ensure all products meet the highest standards of quality and accuracy.

- Can Greatlight assist in customizing precision machining?

- Yes, Greatlight specializes in custom precision machining and offers tailor-made solutions to meet the unique needs of each customer.