The Mysterious PLA: Your Comprehensive Guide to Mastering 3D Printing Favorite Materials

PLA (Polylactic Acid) ruled the top choice for supreme beginners and experienced 3D printing enthusiasts. This biodegradable thermoplastic is derived from renewable resources such as corn starch or sugar cane, combining user-friendliness with impressive versatility. Whether you are making new products or creating artistic designs, understanding PLA is the foundation for success in 3D printing. Let’s dive into everything you need to know.

Why PLA? Explain the key advantages

- Beginner friendly: Low printing temperature (180–220°C) minimizes warpage and does not require heating of the bed.

- Ecological awareness: Biodegradable under industrial composting conditions and comes from renewable energy sources.

- Aesthetic versatility: Available in bright colors, metal, translucent options, and even wood/stone composites.

- Odorless and safe: A mild sweetness (compared to the irritating smoke of ABS), is ideal for home/office use.

- Cost-effective: Affordable pricing reduces barriers to experiments.

PLA’s technical information: Beyond the basics

Although praised for simplicity, PLA has subtle attributes that affect your print:

- Strength and rigidity: High tensile strength but fragile compared to PETG or nylon – the static model is best with fewer flexible parts.

- Thermal sensitivity: Soften at around 60°C; avoid using internal automobiles or electronic equipment and other applications.

- Absorb moisture: PLA absorbs moisture if stored incorrectly, resulting in poor adhesion of string and layer.

- Biodegradability Notes: Controlled industrial compost (50–60°C); it will not decompose in household compost or landfills.

Optimized PLA printing: Professional technology

These settings and tips maximize quality:

- Temperature adjustment:

- Nozzle: 190–210°C (lower start, adjust for better layer bonding).

- Bed: 50–60°C (If unheated, use blue painter’s tape or PEI for bonding).

- Cooling is crucial: Enable 100% fan cooling after the first layer to prevent sagging and sharpen details.

- Speed and retraction:

- Printing speed: 40–80 mm/s (faster speeds may reduce gloss).

- Retract: 40-50 mm/s 4–6 mm to combat string.

- Bed adhesion: Use glue sticks, hair spray or edges (5-8 mm) for high/narrow prints.

Troubleshoot common PLA issues

- Warp: Ensure bed upgrade, slightly increase bed temperature, or use an unfenced environment.

- string: Lower nozzle temperature, increase retraction distance/speed, dry wire (4-6 hours at 45°C).

- Layering: Increase the nozzle temperature by 5-10°C and verify that cooling is not excessive.

- Blockage: Use cold pull to clean the nozzle; avoid thermal vibration (do not cool the PLA quickly after printing).

Innovation with PLA: Advanced Applications

The flexibility of PLA is far beyond the prototype:

- Multi-matter printing: Pair PLA with PVA (water-soluble support) for complex geometry.

- Post-processing: Sand, texture and paint, or waterproof with epoxy coating. Acetone vapor is used only with PLA+ mixture.

- Functional upgrade: Carbon fiber reinforced PLA improves stiffness, while hybrid variants mimic wood or ceramic for artistic finishing.

PLA in a professional environment: from concept to product

For enterprises, PLA will accelerate conception and verification. Its rapid turnover allows the team to iterate design cost-effectively before committing to high-cost production. Whether it is used for packaging models, ergonomic testing or artwork prepared on the market, PLA bridges the gap between imagination and tangible reality.

Utilize professional 3D printing services

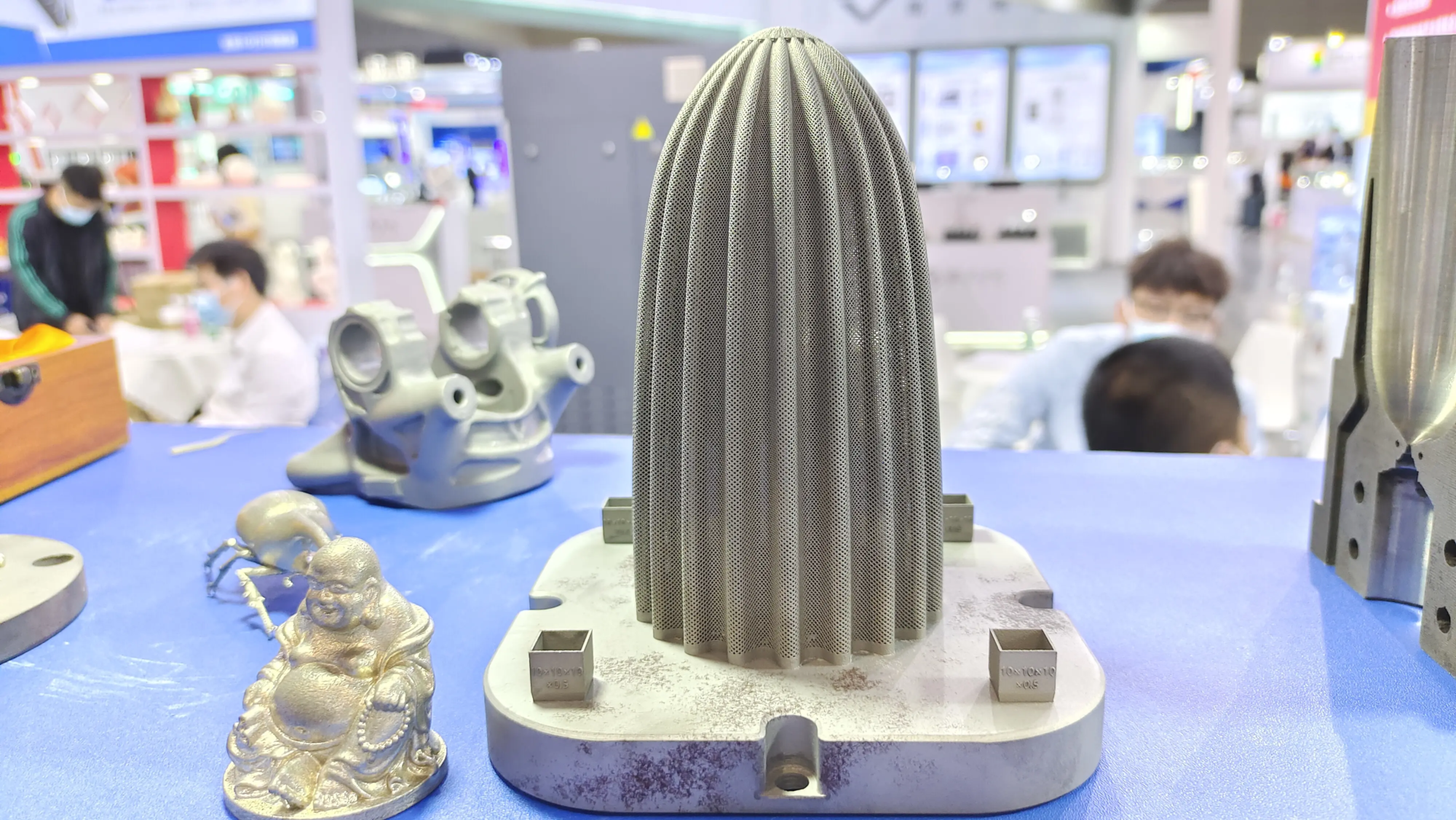

Although desktop printers handle many projects, complex geometry, ultra-high resolution or large-capacity production often benefits from industrial-grade solutions. The company likes it Great Enhance this workflow by providing Advanced 3D printing service The supplemental PLA prints with the following methods:

- Various material libraries: Includes engineering grade thermoplastics and metals through SLM/SLS.

- Super accurate machinery: Multi-laser systems and stringent QA protocols for functional prototypes or end-use parts.

- End-to-end post-processing: Smoothing, dyeing, annealing, processing and heat treatment to achieve tolerances at the aviation level.

By outsourcing complex or high-risk PLA projects to experts, creators can access scalability without sacrificing quality. Great examples are the extended production schedule of Chinese rapid prototyping leaders (especially for highly critical, custom metal parts) while maintaining competitive pricing Vertical integration manufacturing.

The Future of PLA: Sustainability and Innovation

Researchers are enhancing the thermoelasticity of PLAs (such as nanocomposite mixtures) and accelerating biodegradability without compromising printing quality. As the circular economy expands, PLA’s role in ecological manufacturing (material savings with effective 3D printing) uses it as a key material for sustainable innovation.

in conclusion

PLA is the cornerstone of accessible, creative and environmentally responsible 3D printing. Whether you are designing custom widgets or engineering functional prototypes, mastering their properties will bring about endless potential. When projects require accuracy beyond desktop boundaries, working with fast prototype experts, such as Greatlight, can turn vision into reality with speed and reliability. Embrace PLA-Simplicity reaches a refined place.

FAQ section

Q1: Is PLA food safety printed cups or plates?

The original form of PLA is technically non-toxic and food-safe, but the print has microscopic gaps. Sealing with food-grade epoxy is crucial. Note: Some pigments/additives may not be food safe.

Q2: How to store PLA to prevent moisture damage?

Place the filaments in an airtight container with silicone desiccant. For humid climates, vacuum bags add extra protection. The damp filaments hissed, snapshots and fractures in the middle.

Q3: Can PLA prints be recycled?

Yes, but not through curbside recycling programs. Professional facilities turn PLA into recyclable resin. In addition, the ground prints are used for particles for use in DIY regenerating filament machines.

Q4: Why does my PLA break or break under pressure?

Over time, the brittleness of PLA increases. For flexible parts, use PETG or TPU. High-impact PLA mixtures (e.g. PLA+) or annealed prints (heat to 80–100°C for 30 minutes) can also improve toughness.

Question 5: When should I switch from PLA to professional printing services?

Consider outsourcing:

- Large batches (> 50 units) require consistency.

- The key tolerating industrial parts is required for SLM/SLS metal printing.

- Post-processing (e.g., mirror polishing, electronic coating) cannot be used on consumer printers.

Unlock product potential: From PLA prototypes to aviation-grade metal components – connected to trusted manufacturing allies. Greglight offers innovation at speed. Start your fast prototyping journey today.