introduce

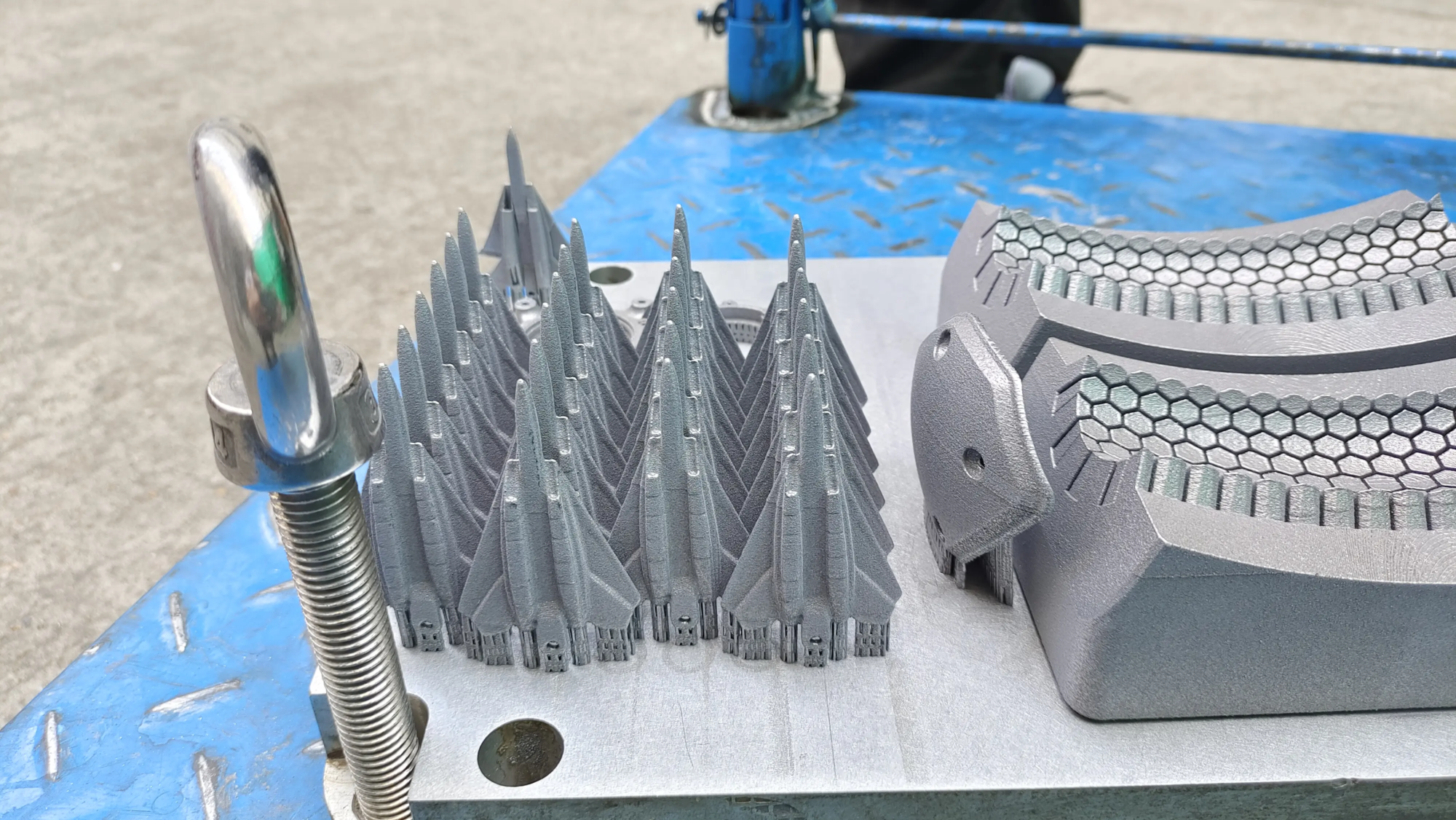

In the complex world of metal 3D printing, achieving flawless parts is not just a design or printer, but a mastering the subtle nuances that determine quality. One of such a key factor, the often overlooked circle of external experts, is Main Tower. Especially important Selective laser melting (SLM) Technology, the main towers ensure consistent melt pool stability, directly affecting the integrity of the parts. As a pioneer in industrial-grade metal additive manufacturing, we dissect this indispensable but essential tool, showing how it can lift your prototype from functional to exceptional.

What is the main tower?

Prime Tower is a dedicated sacrificial structure and is printed next to the main components in SLM 3D printing. Unlike support or construction boards, its only purpose is Plant stability. Here are its functions:

- Layer transition management: At the beginning of each layer, the laser directs its first pulse to the Prime tower. this "Prime numbers" Melt pool, establishing optimal temperature and flow kinetics before the nozzle is moved to the actual section.

- Material consistency: Uninterrupted material flow prevents porosity, splash or "The cold begins" (Inconsistent melting).

- geometry: Usually cylindrical or conical, designed for rapid melting and minimal cross-contamination.

Essentially, the main tower is "Rehearsal stage" For each layer – non-negotiable precision.

Why is the main tower important in SLM metal printing

The accuracy of SLM depends on laser accuracy and thermal stability. No main tower:

- Exudation/sputtering: The idle nozzle may drip half a mole of material onto the build plate, resulting in inaccuracy.

- The first shot of inconsistent: The first laser pulse after layer changes usually lacks energy consistency and risks weak layer adhesion.

- Material pollution: Unused powder degrades, if not dissolved between cycles, it will affect the metallurgical properties.

For mission critical sectors such as aerospace or medical implants (invalid internal structures and tensile strengths), towers must be a guarantee for invisible defects.

Strategic Major Tower Design: Best Practices

Not all major towers are equal. Optimization minimizes waste while maximizing chemotherapy:

-

Placement and Orientation:

- Located near the edge of the part to shorten laser travel, but avoid thermal interference.

- Use multiple Prime Towers for high-density buildings to minimize travel time.

-

Dimensions and geometric shapes:

- Diameter: 10-20mm (adjust according to part volume; larger parts require a wider starting surface).

- Shape: Tapered tower upward taper taper to reduce material usage while maintaining surface area contact.

-

calibration:

- Laser Power/Sweep: The pulse frequency is slightly higher without overheating.

- Layer synchronization: The height of the synchronous tower is synchronized layer by layer with the main part.

- Multi-matter printing:

- A separate main column is used for each material to prevent cross-alloy contamination.

Trade-offs: Efficiency and Necessity

| The main tower is not free. Consider these pros and cons: | Advantages | shortcoming |

|---|---|---|

| Reduce layer startup defects by up to 30% | Material costs increased by 3-8% | |

| Enhanced metallurgical uniformity | Increase build time ~5–15% | |

| Low waste rate in high-value construction | Need to be manually deleted and printed |

For prototypes with unnegotiable dimensional accuracy, the trade-off is reasonable.

Greglight’s Prime Tower optimization method

At Greatlight, our SLM workflow integrates cutting-edge technology to offset the limitations of major towers:

- Dual laser system: High-precision lasers alternate between main towers and parts, minimizing time loss.

- AI-driven slices: Proprietary algorithms calculate the minimum mass tower size required for each geometric material.

- Mixed deposition: Post-printing, separated towers by CNC machining (including in our finishing service), 95% of unused metal powder was recycled.

Our certified technicians tailor Prime Tower parameters (whether it is titanium, Inconel® or aluminum) to ensure compliance with ASTM/ISO standards.

in conclusion

The main towers give examples "hidden" Engineering details define success in metal 3D printing. Although it increases marginal costs, its role in ensuring a defect-free layer makes it invaluable for industrial applications. With Advanced SLM hardware by mastering tools like Prime Towers Grevlight always offers fast prototype solutions, and precise solutions go beyond compromises. From aerospace turbines to surgical instruments, we transformed the CAD blueprint into a certified component with a reliable structural basis, behind a post-processing finish that meets the highest industry benchmarks.

FAQ: The main towers in metal 3D printing

Q1: Can I 3D print metal parts without a tower?

Yes, but only for non-critical geometric or conceptual models. For high-density or thin-walled structures, skipping it can risk stratification and voiding.

Question 2: Will the main tower increase printing costs?

Depending on the tower size, the material cost increases by 3-8%, but this offsets the higher cost of scratching defective parts. For batch production, we optimize tower sharing across multiple components.

Q3: How to delete the main tower and print it?

At Greatlight, we use precision wire EDM (electrical machining) or CNC milling. Polish the surface to prevent stress concentrator.

Question 4: Can reused tower materials be reused?

Yes, our closed-loop sieving and plasma-spherical system recovers > 95% of unused powder. Reused powders are chemically analyzed to ensure compliance.

Question 5: Is the Prime Tower strategy for Greatlight Wustlight Wustlame Wustlight for Exotic alloys?

Absolutely. Refractory metals (e.g., tungsten) require adjusted laser frequency and tower insulation. Our materials science team customizes the parameters to the thermal profile of each alloy.

Question 6: Are there any alternatives to the main tower?

Techniques like laser pre-insert or wall cleaning exist, but are less reliable for large buildings. The main tower remains the gold standard for SLM.

Customize your precision metal parts now

Ready to 3D printing with industrial-grade SLM? Greatlight® combines German-designed machines, material expertise and ISO-certified post-processing to deliver prototypes at a speed of 60%, which is the speed at which the best value pricing in China is. Request a quote now →

Innovation meets uncompromising precision.