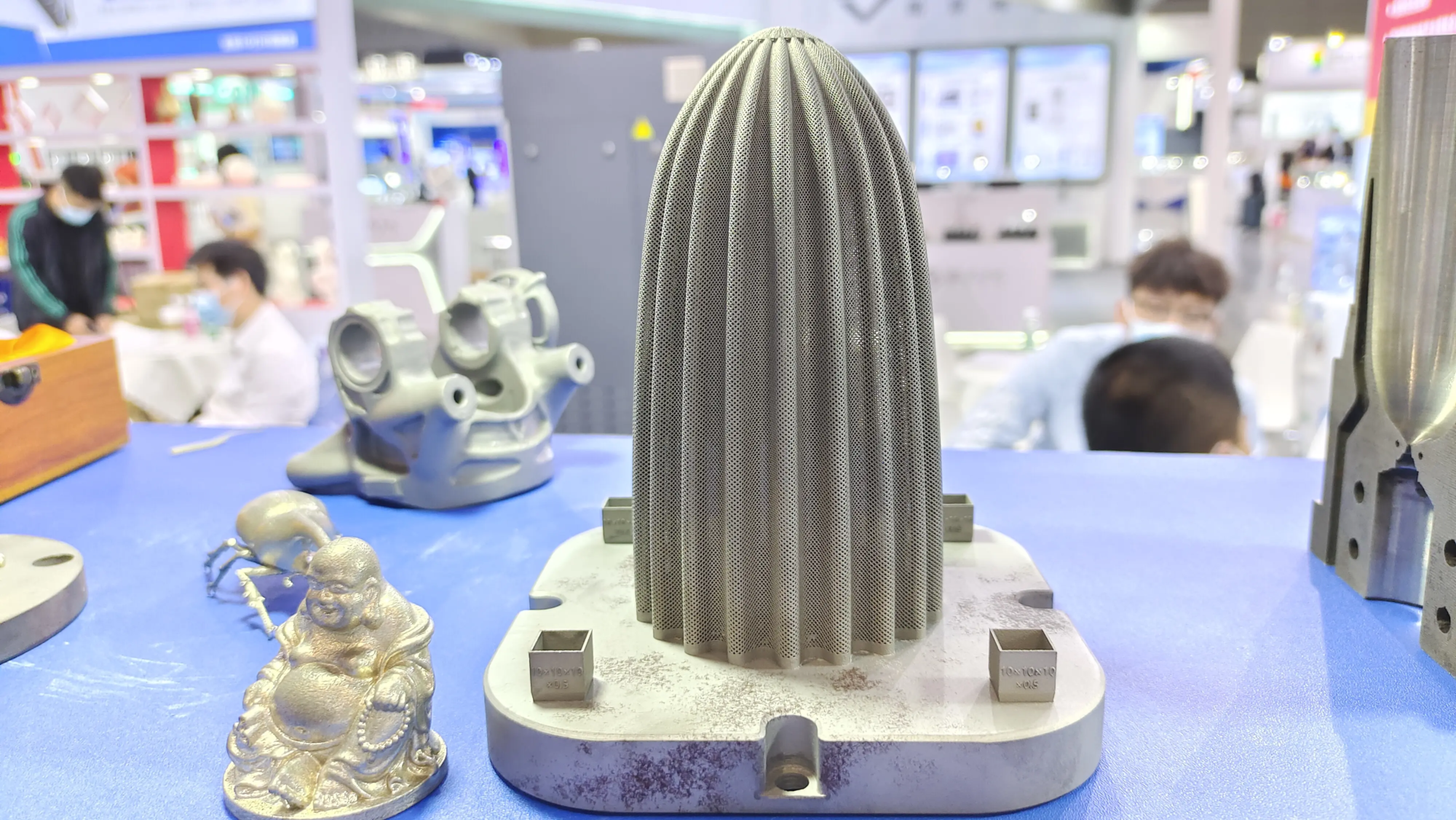

Printing 608 bearings is a highly specialized process that requires advanced technology and expertise. At Greatlight, a professional rapid prototyping manufacturer from China, we have the ability to produce high-quality 608 bearings using state-of-the-art SLM 3D printer equipment and production technology. Our team of experts can professionally solve the problem of rapid metal parts production, providing one-stop after-processing and completion services to ensure your bearings meet the highest standards of quality and accuracy.

608 Bearing is a deep groove ball bearing that is commonly used in a wide range of applications including skateboard wheels, inline ice wheels and other high-speed rotating equipment. These bearings are designed to withstand high radial loads and are known for their high speed and low noise operation. However, using traditional manufacturing methods to produce 608 bearings can be time-consuming and expensive, which is where 3D printing is located.

Using our advanced SLM 3D printing technology, we can produce 608 bearings with complex geometry and structures that cannot be produced using traditional manufacturing methods. Our 3D printing process allows the use of customized materials, shapes and sizes to create bearings that can be tailored to meet the specific needs of our customers. Furthermore, our 3D printing process is much faster than traditional manufacturing methods, which allows us to produce bearings quickly and efficiently.

At Greatlight, we offer a range of materials for printing 608 bearings, including stainless steel, titanium and aluminum. Our team of experts can help you select the best material for your bearings based on your specific application and requirements. We also offer a range of after-processing and finishing services, including machining, grinding and polishing to ensure your bearings meet the highest quality and accuracy.

One of the benefits of printing 608 bearings using 3D printing technology is the ability to produce bearings with complex geometries and structures. The ability of traditional manufacturing methods to produce complex shapes and structures may be limited, which may result in the bearings not being optimized for performance. Using 3D printing technology, we can produce bearings with customized geometry and structures, which can improve their performance and life.

Another benefit of printing 608 bearings using 3D printing technology is the ability to produce bearings quickly and efficiently. Traditional manufacturing methods can be time-consuming and expensive, which can lead to longer lead times and high costs. Using 3D printing technology, we can produce bearings quickly and efficiently, which can help reduce lead time and cost.

In short, printing 608 bearings using 3D printing technology is a highly specialized process that requires advanced technology and expertise. At Greatlight, we have the capability to produce high-quality 608 bearings using state-of-the-art SLM 3D printer equipment and production technology. Our team of experts can professionally solve the problem of rapid metal parts production, providing one-stop after-processing and completion services to ensure your bearings meet the highest standards of quality and accuracy.

FAQ:

Q: What is the difference between traditional manufacturing methods and 3D printing technology that produces 608 bearings?

A: The ability of traditional manufacturing methods to produce complex shapes and structures may be limited, while 3D printing technology can create bearings with custom geometry and structures.

Q: What material can be used to print 608 bearings?

A: We offer a range of materials for printing 608 bearings, including stainless steel, titanium and aluminum.

Q: How long does it take to produce 608 bearings using 3D printing technology?

A: Our 3D printing process is much faster than traditional manufacturing methods, allowing us to produce bearings quickly and efficiently.

Q: Can I customize the size and shape of the 608 bearing?

A: Yes, our 3D printing technology allows the creation of bearings with customized materials, shapes and sizes.

Q: Do you provide after-processing and completion services for 608 bearings?

A: Yes, we offer a range of after-processing and finishing services, including machining, grinding and polishing to ensure your bearings meet the highest quality and accuracy standards.

ISO 9001 Factory