Bringing game icons to life: The art of 3D printing companion cubes

In the game world, few inanimate objects arouse emotions like Valve’s weighted companions Portal series. With its vivid white and pink design and mysterious heart symbols, it’s no wonder that enthusiasts dream of having a tangible piece of this universe. Thanks to Senior Metal 3D printingThis dream can now be realized, but creating a faithful, durable replica requires precise engineering. Let’s explore professional rapid prototypes, especially Selective laser melting (SLM)convert digital models into perfect metal monuments.

Why Metal 3D Printing Raises the Companion Cube

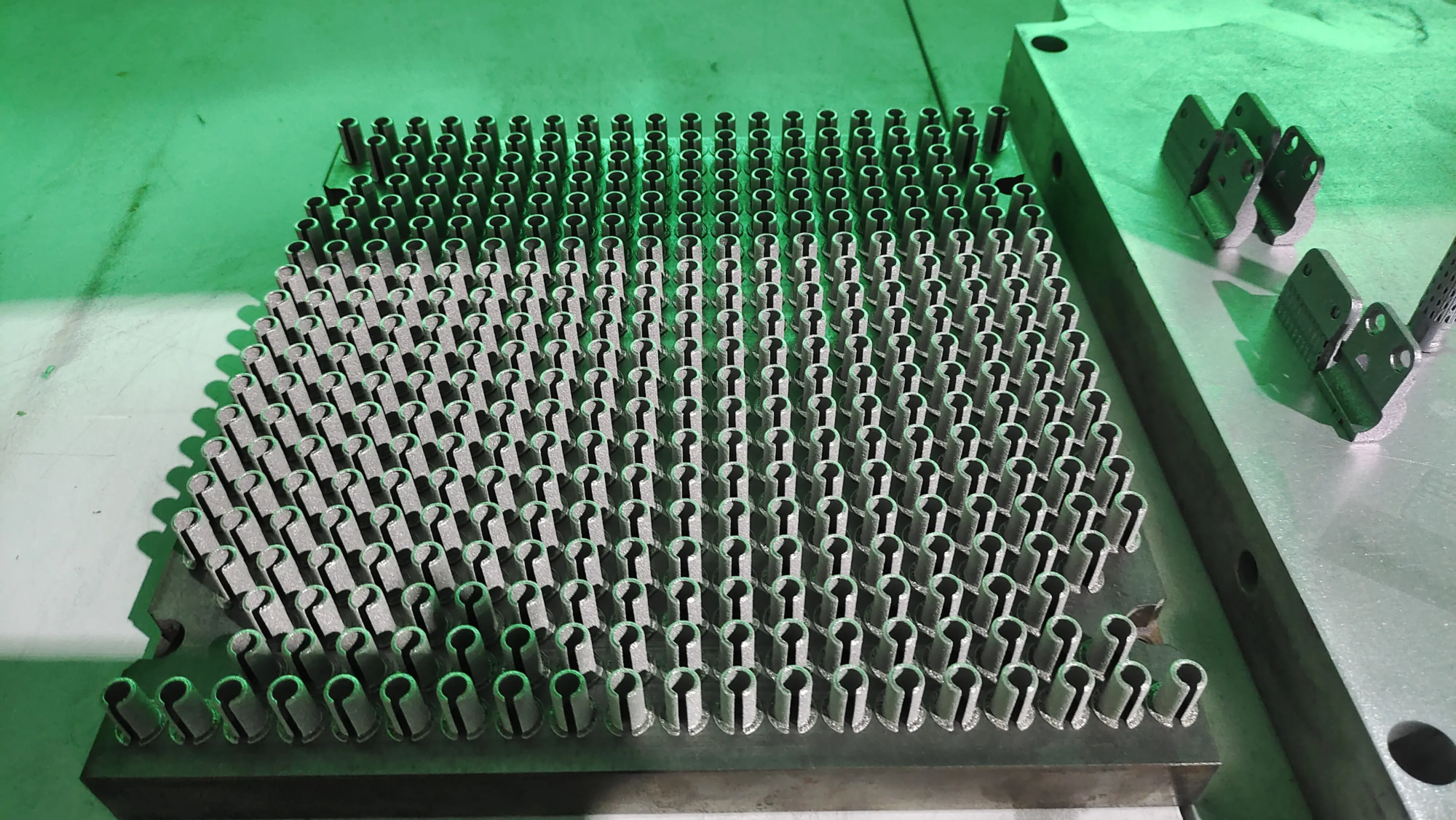

Traditional plastic prints can capture the form of cubes, but they lack the weight, durability and reputation of metals. SLM technology builds cubes layer by layer from fine metal powder and fuses them with high-power lasers. This approach solves key challenges:

- Geometric complexity: As we all know, for subtraction methods, it is well known that the concave hearts of cubes, smooth faces and sharp edges are difficult. SLM builds these features with microscopic accuracy without the need for expensive tools.

- Material integrity: Similar metals aluminum (Light and corrosion resistant) or Stainless steel (To create a heavier industrial feel) Ensure the cube is subject to manipulation while mimicking the aesthetics of the game.

- Structural integrity: The internal lattice structure can be printed to optimize weight without damaging strength – for large cubes.

Great Advantage: Accurate and artistic

exist GreatWe combine cutting-edge SLM printers with deep expertise in gaming and collectible manufacturing. Here is our way to ensure your companion cube is excellent:

- SLM mastery: Our industrial-grade printers process complex geometry with layer resolution of 30-50 microns, capturing every curve of the heart pattern and ensuring uniform surface quality. Unlike Fusion Deposition Modeling (FDM), SLM produces completely dense parts, eliminating weaknesses.

- Material versatility: Aluminum alloy provides a lightweight, smooth finish; titanium provides unparalleled strength to weight ratio; stainless steel provides a solid true industrial look. Custom alloys are also available.

- Seamless finish: Post-processing is where the cube really shines. Our one-stop service includes:

- Grinding and polishing:For mirror-smooth surfaces.

- plating: Chrome or nickel coating for signature reflective effect.

- Laser etching: Crisp the pink heart with a vibrant, fading-resistant color filler.

- Customized aging: Optional weathering "Retro Aperture Science" look.

Case Study: From Pixels to Perfect

The latest customer requested the use of a 15cm aluminum companion cube with brushed metal plating and neon pink heart details. Our process:

- optimization: Digitally reinforced corners and hollowed out the core to save 40% weight.

- print: SLM was printed with ALSI10mg of <0.1mm tolerance within 18 hours.

- finishing: Steam polishing + electroplating + UV enamel of the heart.

result? There is no difference between display and virtual originals.

Beyond Aesthetics: Function and Innovation

More interested in decoration? We integrate functional twists:

- McGell Base: Use embedded magnets to levitate your cube.

- Hidden compartment: Add storage via the detachable panel.

- LED lighting: Backlight center powered by the internal battery pack.

in conclusion

The weighted companion cube is a symbol of engineering creativity in novels and reality. 3D printing with metal requires a synergy between artistic vision and technical capabilities, what is this Great deliver. As a leader Chinese Rapid Prototyping ExpertWe incorporate advanced SLM technology, materials science expertise and comprehensive post-processing to turn digital fantasy into heirloom quality artifacts. Whether you are a collector, game studio or industrial designer, empower your creative abilities with uncompromising precision.

Customize your metal companion cube, or any visionary project – today is great. Request a quote and experience a prototype rise.

FAQ: 3D Printing of Peer Cubes

1. How long does it take to print a metal companion cube?

Production time depends on size and complexity. A 10 cm cube takes 12–24 hours to print + 3-5 days. An expedited selection is available.

2. What metals can you use? Which one is the best?

Aluminum (ALSI10MG) is popular for its lightness and gloss. Stainless steel (316 liters) provides a solidity; titanium (Ti64) is of high quality. We recommend that according to use case – eg, aluminum for table decoration, steel for outdoor installation.

3. Can you accurately copy the pink heart?

Absolutely. We use enamel fillers, colored resins or laser markers to achieve a vibrant, durable heart with Pantone references.

4. Is internal support required? How do they delete it?

SLM printing requires support for dangling (such as the heart cavity). These will be removed by tangent and then done manually to remove the mark without visible scars.

5. What is the maximum size possible?

Our SLM printer can hold 25 cm cubes. Larger sizes can be divided and assembled by interlocking joints.

6. How to provide design files?

Provides .stl or .obj files. Our engineers will optimize its printability and strength at no extra cost.

7. Do you offer a non-metallic version?

Yes! We also specialize in lightweight or colorful variants of high-fine resin, nylon and carbon fiber printing.

Unleash your creativity Great– Every cube is a masterpiece. 🧊💖