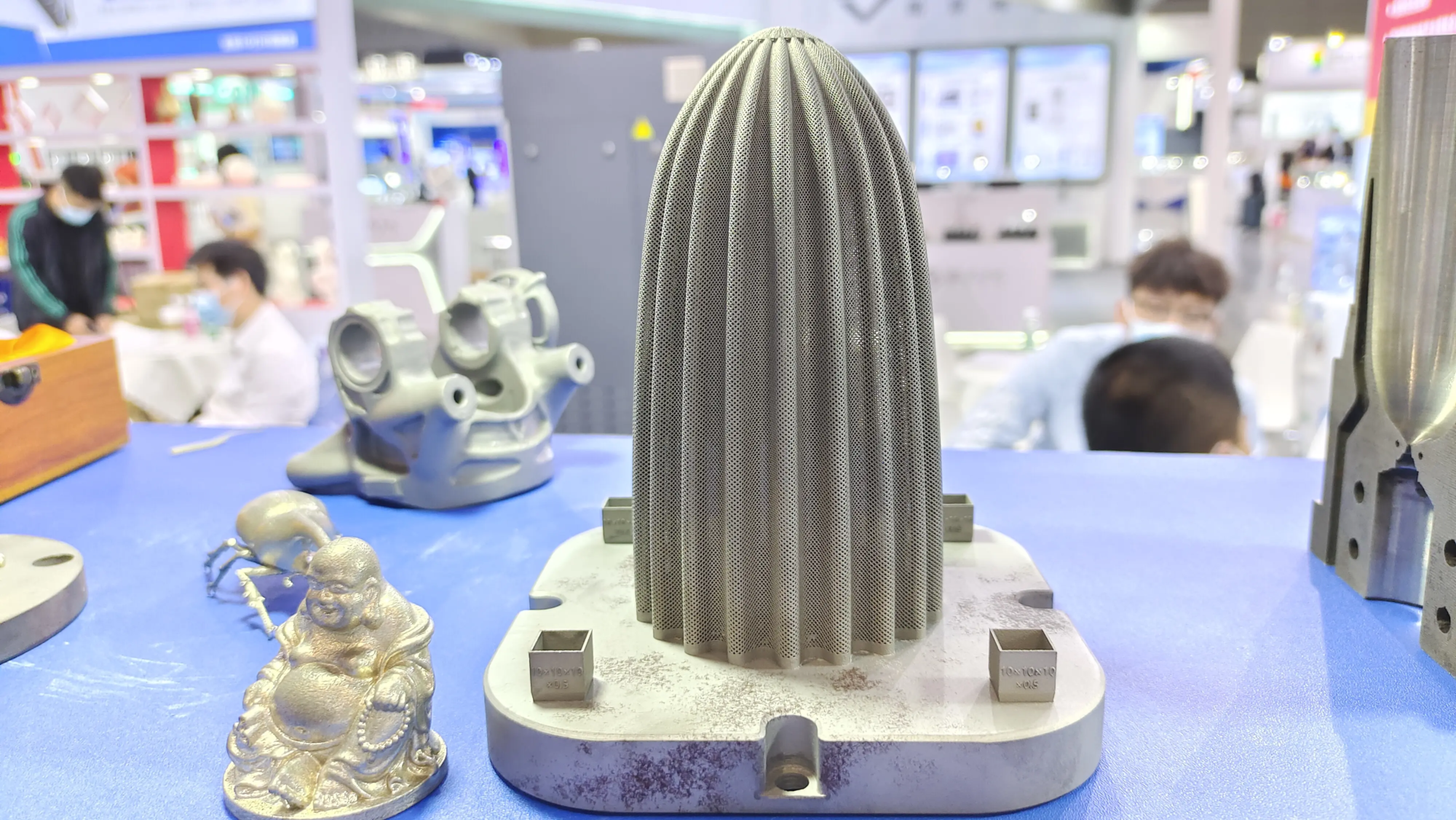

When creating complex and complex designs, such as the iconic halo armor of popular video game franchises, traditional manufacturing methods are often insufficient. This is the source of 3D printing, providing a game-changing solution to easily produce highly detailed and customized parts. At Greatlight, a team of experts from China’s renowned rapid prototyping manufacturer, leverages advanced SLM (selective laser melting) 3D printing equipment and cutting-edge production technology to bring even the most complex designs to life.

The stylish and futuristic design of halo armor is a perfect example of a complex structure that can be accurately copied using 3D printing technology. By utilizing metal parts to quickly prototyping, Greatlight creates highly detailed and customized parts that match the original design with precise original design. The company’s advanced equipment and production technology enables the creation of complex geometric shapes and internal structures using traditional manufacturing methods.

One of the important advantages of using 3D printing to create halo armor is the ability to customize the design to your personal preferences. Greatlight offers a wide range of materials that can be used for printing, and most materials can be quickly customized and processed. This means enthusiasts and fans of the Halo franchise can create their own custom armored pieces, such as helmets, chest plates or gloves, with intricate details and designs that match their unique preferences.

In addition to customization, Greatlight also offers one-stop post-processing and completion services to ensure the highest quality of the final product. The company’s team of experts uses advanced technologies such as grinding, polishing and coating to achieve a smooth finish that matches the original design. The focus on detail and commitment to quality has made him a reputation as one of the best rapid prototype companies in China.

For those who want to create their own custom halo armor or other sophisticated designs, Greatlight offers a range of services and solutions. The company’s website provides customers with a platform to upload their designs, select materials and select from a range of completion options. Greglight’s strong focus on customer satisfaction and commitment to delivering high-quality products has become the preferred destination for enthusiasts and professionals.

In short, creating custom halo armor using 3D printing technology is a complex task that requires advanced equipment, production technology, and expertise. With its state-of-the-art SLM 3D printing equipment and expert team, Greglight has the capability to demand even the most complex designs. Greatlight has become a leading player in the rapid prototype industry by offering customization options, one-stop post-processing and finishing services, and a commitment to quality.

FAQ:

Q: What material can be used to print halo armor?

A: Greatlight offers a wide range of materials that can be used for printing, including metals, plastics and ceramics.

Q: Can I customize the design of the halo armor?

A: Yes, Greglight offers customization options that allow you to create your own unique designs.

Q: What time is the turnaround time for printing and completing custom halo armor?

A: Turnover time depends on the complexity of the design and the materials used. However, Greatlight offers quick processing and completion services to ensure your product is delivered as quickly as possible.

Q: How do I upload my design and order custom halo armor?

A: You can upload designs and order custom halo armor through Greatlight’s website, and you can also choose materials and finishing options.

Q: Is Greglight a well-known company?

A: Yes, Greglight is a well-known and well-known company that is very focused on customer satisfaction and commitment to delivering high-quality products.

ISO 9001 Factory