In the manufacturing and production sectors, the concept of heroism is often overlooked, but it plays a crucial role in the creation of innovative products and solutions. Printing heroism in particular refers to the use of advanced printing technology to produce complex and customized parts, components and products. This blog post will dive into the world of print heroism, highlighting its importance, applications and benefits, focusing on the services provided by Greatlight, a leading rapid prototyping manufacturer from China.

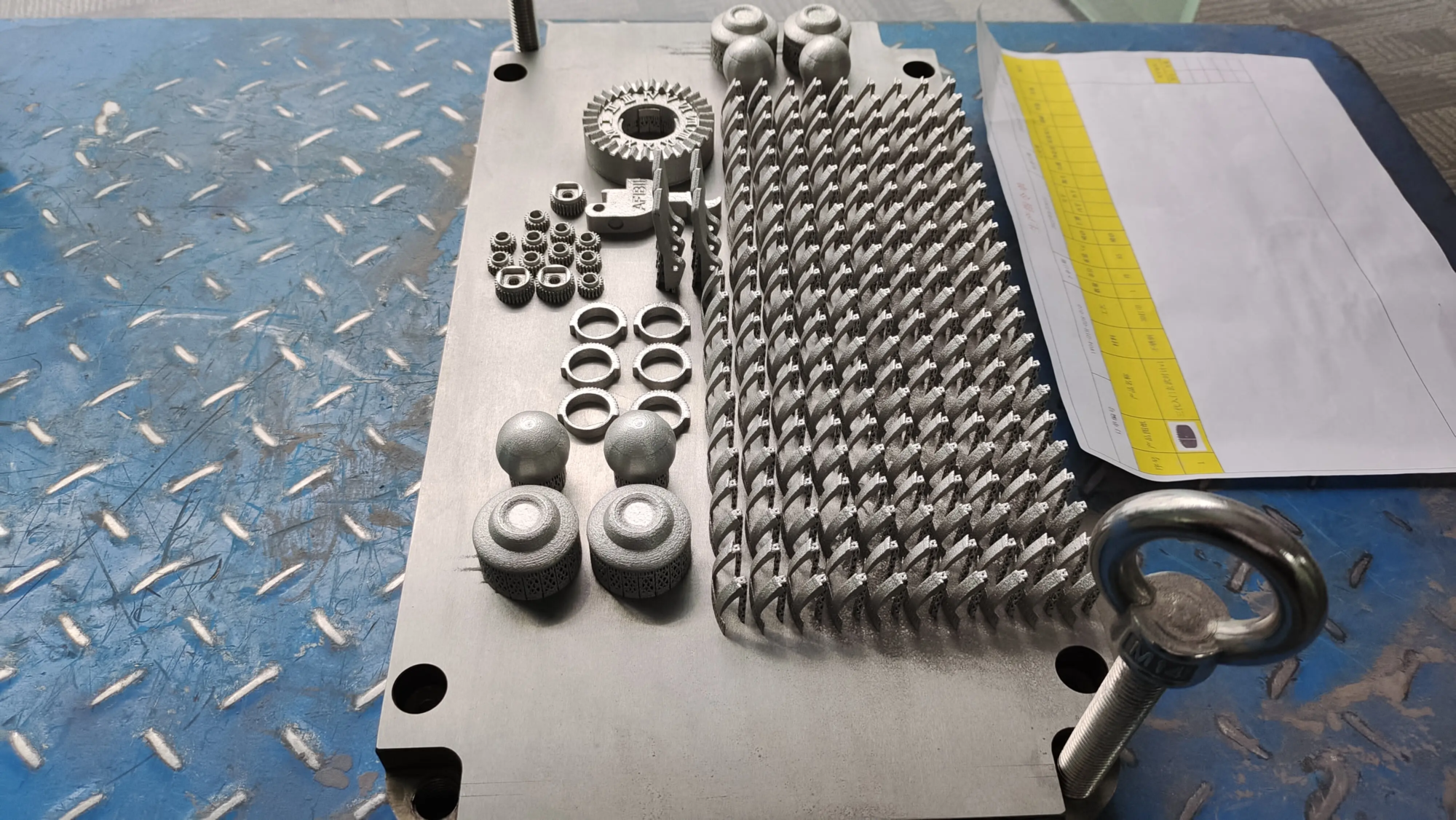

The forefront of printing heroism is the utilization of cutting-edge technologies, such as selective laser melting (SLM) 3D printing equipment. This technology enables the creation of complex metal parts with unparalleled accuracy and accuracy. With its advanced SLM 3D printers, Greglight has become a pioneer in the field of rapid prototyping, providing professional solutions for metal parts production. The company’s expertise in post-processing and completion services ensures that the final product meets the highest standards of quality and durability.

One of the important advantages of typographic heroism is the ability to customize the materials and processes according to specific requirements. Greatlight offers a wide range of customizable materials that can be processed quickly to meet customer needs. This flexibility is particularly valuable in industries where custom parts and components are critical, such as aerospace, automotive and medical equipment. The company’s commitment to precise machining and rapid prototyping makes it one of the best reputations in the business and has a strong influence in the Chinese market.

The applications of printing heroism are diverse and profound. From creating complex geometric shapes and structures to generating functional prototypes and end-use parts, the possibilities are endless. In particular, using SLM 3D printing technology, parts with complex internal structures can be created that cannot be generated using traditional manufacturing methods. This has great significance for industries that are critical to weight loss, strength increase and performance improvements, such as the aerospace and automotive sectors.

In addition to its technological interests, printing heroism offers economic advantages. By reducing production time and costs, companies can bring their products to the market faster, thus gaining a competitive advantage. The use of rapid prototypes also enables businesses to test and refine their products, thereby reducing the risk of errors and defects. This, in turn, improves customer satisfaction and loyalty, ultimately driving business growth and success.

In short, printing heroism is a revolutionary force in the world of manufacturing and production. With its advanced technology, customizable materials and precise machining capabilities, Gremphime is at the forefront of this revolution. By leveraging the power of print heroism, companies can create innovative products, reduce production costs and bring their ideas to life. Whether you are a startup or an established business, Greatlight offers services that can help you achieve your goals and stay ahead of the curve.

FAQ:

Q: What is printing heroism?

A: Printing heroism refers to the use of advanced printing techniques (such as SLM 3D printing) to produce complex and customized parts, components and products.

Q: What are the benefits of printing heroism?

A: The benefits of typographic heroism include increased accuracy and accuracy, reduced production time and cost, and the ability to create complex geometric shapes and structures.

Q: Which industries can benefit from printing heroism?

A: Industry such as aerospace, automotive, medical equipment and consumer products can benefit from printing heroism, especially when custom parts and components are crucial.

Q: How do I start printing heroism?

A: To start printing heroism, please contact Greatlight, a leading rapid prototyping manufacturer from China to discuss your specific needs and requirements.

Q: What is the difference between SLM 3D printing and traditional manufacturing methods?

A: SLM 3D printing allows the creation of parts with complex internal structures that cannot be generated using traditional manufacturing methods and provide higher accuracy and accuracy.

ISO 9001 Factory