blog post

Woodworking combines artistry with precision. Achieving consistently perfect joints (dovetails, mortises, tenons, box joints) requires not only skill but often complex jigs traditionally made of wood or metal. This process can be time-consuming, expensive for one-off projects, and limiting for complex designs. Fortunately, modern machining and rapid prototyping technologies are changing this process. Enter 3D printing fixture: A game changer that provides woodworkers with unprecedented accuracy, customization and efficiency.

The Precision Revolution: How 3D Printed Fixtures Work

Imagine designing a custom dovetail fixture on your computer, precisely tailored to your workpiece size and desired angle, and then printing it overnight. 3D printing enables exactly this. Woodworkers use CAD software such as Fusion 360 or SketchUp to design jigs that are optimized for specific cuts and joints. The design files are sent to a 3D printer, which builds the jig layer by layer out of durable plastic or metal (for extreme requirements). The printed jig clamps onto the workpiece, guiding the router, chisel or saw with absolute consistency, eliminating human error in marking or alignment.

Why use 3D printed fixtures?

- Unparalleled accuracy and repeatability: Micron-level joint geometric accuracy is achieved batch after batch. Ideal for complex joints such as compound angled Japanese joinery or intricate decorative patterns.

- Completely customizable: Clamps designed for use with unique angles, irregular workpiece shapes, or niche joint types not possible with off-the-shelf clamps.

- Cost effectiveness: No need for expensive CNC machined metal fixtures for prototypes or low-volume production. Plastic wire is very affordable.

- Speed and iteration: Design changes are digital. Do I need to adjust the tenon width? Modify CAD files and reprint them in hours, not days. Rapid prototyping accelerates design refinement.

- Release complexity: Easily integrate complex features into the fixture (locating pins for multi-step operations, bending rails, dust removal ports), breaking traditional manufacturing methods.

- Auxiliary functions: Brings high-precision clamping capabilities to small shops, hobbyists, and custom furniture makers without industrial machinery.

Customized solutions for every woodworking task

3D printed fixtures shine in a variety of applications:

- Router Guide: Templates for perfect mortises, dados, profiles, inlaid cavities and decorative edge treatments.

- Drilling and boring: Positioning jig ensures perfect alignment of pins or domino holes.

- Cutting and sawing: Angle guides, custom sleds or bandsaw curve templates for precise mitering.

- Assembly alignment: Fixtures that hold complex glued pieces into perfectly square or precise angles.

- Professional joints: Jig useful for making sliding dovetails, snap joints, or complex crimped joints.

Choosing the right material: plastic vs. metal

Most woodworking jigs use common Engineering plastics:

- People’s Liberation Army: Affordable and sturdy, suitable for light to moderate use. Susceptible to creep under sustained heavy loads.

- Polyethylene glycol: There is an excellent balance between toughness, impact resistance and temperature stability for most mill/saw applications.

- ABS: Good temperature resistance and impact strength, but requires a heated chamber for optimal printing.

- Nylon (PA): Extremely tough and wear-resistant, ideal for high-wear rails or production environments.

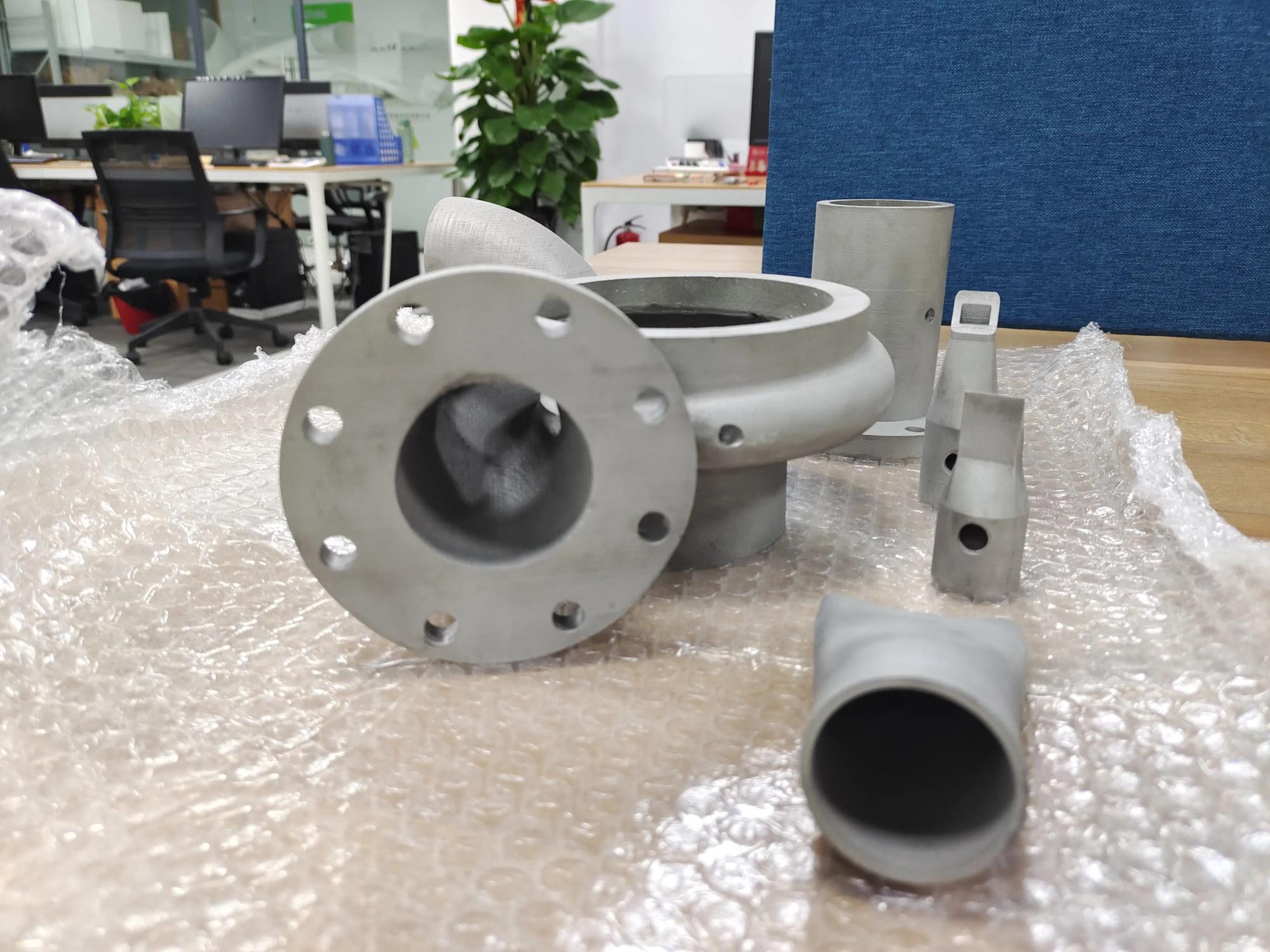

However, for extremely high loads, high temperatures or industrial production environments that require absolute rigidity and wear resistance for thousands of cycles, Metal 3D printing fixture become crucial. use Selective Laser Melting (SLM) Materials such as craft, aluminum alloys, stainless steel alloys, tool steel or titanium alloys can be printed directly from CAD files. They offer superior durability, accuracy, thermal stability and strength comparable to conventionally machined metal fixtures, but without the limitations imposed by machining complex geometries. Companies specializing in metal prototyping, e.g. huge lightproviding valuable solutions here.

Turn your vision into reality

Follow a simplified process for using 3D printed fixtures:

- design: Model the fixture in CAD software, ensuring gaps, clamping points and alignment features.

- Material selection: Choose plastic for most tasks, or consider metal for heavy-duty needs with prototyping experts.

- Print: Use your own plastic printer. For metal or high-fidelity, high-precision parts (even plastic), hire a rapid prototyping expert.

- Validation and calibration: Make sure you have a good fit with the workpiece and tool before making critical cuts.

- implement: Clamp and cut/route/drill with unparalleled confidence.

The role of an advanced prototyping partner

While desktop plastic printing offers tremendous opportunities, boundary-pushing projects require industrial-grade expertise. For carpenters in need Precision metal components, Extremely complex geometriesor Robust, production-ready fixturesworking with a professional rapid prototyping manufacturer yields superior results. Combining advanced metal printing with expert engineering insight to ensure flawless functionality and longevity.

in conclusion

3D printed jigs transform woodworking from a craft limited by traditional tools into a field with unlimited potential. They democratize precision, enable customization, unlock complex designs, and significantly reduce the time and cost of fixture manufacturing. Whether leveraging an easily accessible desktop printer or working with the advanced prototyping experts at Metal Solutions, integrating 3D printed fixtures into your workflow is a definite leap forward. Employ this technology to master perfect joints, streamline production, and enable complex designs previously thought impractical. It’s not just a new tool, it’s an advancement in craftsmanship.

Frequently Asked Questions (FAQ)

Q1: Can desktop 3D printers produce fixtures suitable for routers?

Answer: Of course! Printers using PETG, ABS or nylon filament produce highly durable jigs that can withstand milling forces and are suitable for both hobbyists and light professional use. Clamp securely and understand the forces involved.

Question 2: How does 3D printing compare to MDF or aluminum CNC cutting jigs?

Answer: Both CNC machining and 3D printing can produce precision fixtures, but their advantages are different. CNC machining is suitable for simpler profiles and requires machining setup. The advantages of 3D printing are complex internal geometries, rapid iteration, lower setup costs, and elimination of tool path constraints.

Q3: Are metal 3D printing fixtures cost-effective?

A: For prototyping complex geometries or low-volume production, metal printing is more cost-effective than traditional machining – eliminating tooling and complex setups. As production volume increases, the cost per part decreases significantly.

Question 4: What tolerances can be achieved with 3D printed fixtures?

A: High-precision fused deposition modeling (FDM) printers can reliably achieve tolerances of ±0.1mm–0.2mm. Metal SLM printing can achieve ~±0.05mm–0.1mm tolerances – comparable to machining – ideal for demanding woodworking applications.

Q5: How do I start designing my own 3D printed fixture?

A: Analyze your cutting tool dimensions, accurately measure the workpiece, understand clamping locations, and then use CAD software to incorporate these constraints into the fixture design. There are tons of sample tutorials online!

Q6: Where can I find high-precision metal 3D printing fixtures?

Answer: Professional rapid prototyping manufacturers such as GreatLight uses industrial-grade SLM 3D printers, capable of producing precision metal fixtures from aluminum, stainless steel, tool steel or titanium alloys, with professional post-processing for optimal results. They specialize in turning complex computer designs into powerful tools.