With the advent of 3D printing technology, the music world has undergone a major transformation. One area that benefits a lot from this innovation is the production of trumpet mouthpieces. Traditionally, trumpets are made of materials such as brass, bronze or silver, and the manufacturing process is time-consuming and labor-intensive. But with the advent of 3D printing, musicians and manufacturers can now create custom trumpet mouthpieces with unprecedented precision and speed.

Greglight is a professional rapid prototype manufacturer that has been at the forefront of this revolution. Equipped with advanced SLM 3D printers and production technology, Greatlight can solve complex rapid prototyping problems of metal parts and provides one-stop post-processing and finishing services. This means that musicians can now design and make custom trumpet mouthpieces to meet their specific needs and preferences.

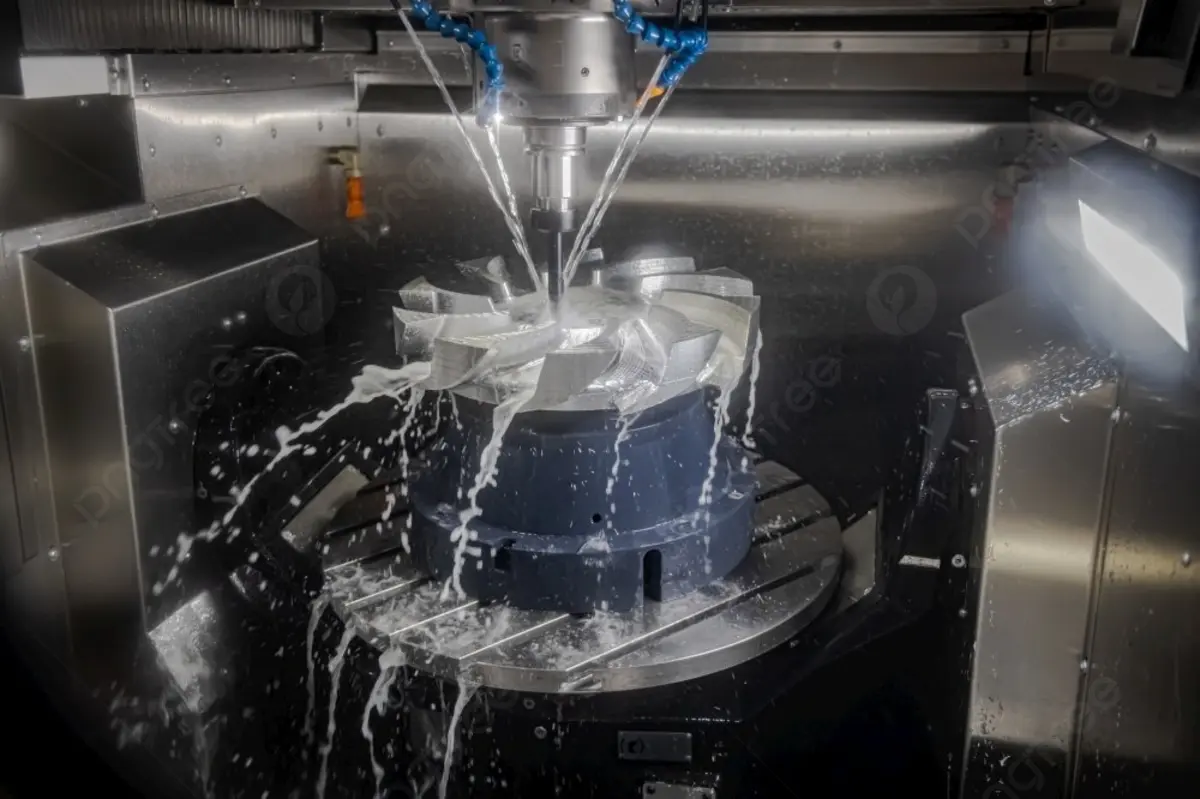

The process of printing a trumpet mouthpiece involves several stages. First, computer-aided design (CAD) software is used to create the design, taking into account factors such as musician support, aerial support, and tone preferences. The design is then sent to a 3D printer, which uses lasers to fuse metal powders layer by layer to create a cigarette mouthpiece. The final product is a highly accurate, custom trumpet mouthpiece that enhances the musician’s performance.

One of the important advantages of 3D printed trumpet mouthpieces is the level of customization it offers. Now, musicians can design cigarette holders tailored to their specific needs, such as adjusting edge width, cup depth, or throat size. This level of customization can help improve the tone, tone and overall performance of the musician. Furthermore, 3D printing allows for the creation of complex geometric shapes and internal structures that cannot be produced using traditional manufacturing methods.

Another benefit of 3D printed trumpet mouthpieces is production speed. Traditional manufacturing methods can take weeks or even months to produce a single cigarette holder. By contrast, 3D printing can create a mouthpiece within a few days, allowing musicians to quickly test and refine their designs. This quick prototyping capability also enables manufacturers to produce small batches or disposable mouthpieces, an attractive option for musicians who need unique or custom mouthpieces.

Greatlight’s expertise in rapid prototyping and 3D printing makes it an ideal partner for musicians and manufacturers looking to create custom trumpet flutes. With its advanced equipment and production technology, Greatlight can produce high-quality mouthpieces that meet the strict standards of professional musicians. In addition, its one-stop post-processing and finishing service ensures that the mouthpiece is refined and polished to perfection and can be used in performances.

In short, the emergence of 3D printing technology has revolutionized the production of trumpet mouthpieces, providing unprecedented customization, speed and accuracy. Greatlight’s expertise in rapid prototyping and 3D printing makes it a leading manufacturer of custom trumpets to meet the needs of musicians and manufacturers around the world. Whether you are a professional musician or a music lover, 3D printed trumpet mouthpieces offer a game-changer opportunity to take your performance and take your music to the next level.

FAQ:

Q: What materials can be used to print small mouth blowers?

A: Greglight can print small trumpets using various materials including metals such as brass, bronze and silver.

Q: How long does it take to produce a 3D printed small cigarette holder?

A: The production time of 3D printed small cigarette holders may vary depending on the complexity of the design, but usually takes several days to a week.

Q: Can I customize the design of the trumpet?

A: Yes, Greglight offers custom services that allow musicians to design their cigarette holders according to their specific needs and preferences.

Q: Are 3D printed trumpet mouthpieces durable and long-lasting?

A: Yes, 3D printed trumpet mouthpieces are highly durable and durable thanks to the advanced materials and production techniques used by Greatlight.

Q: Can I order a custom small cigarette holder or do I need to order in bulk?

A: Greatlight offers small batch and one-time production services, making it possible to order a single customized small mouth.

ISO 9001 Factory