Bringing the Guardian of the Galaxy into your world: A guide to 3D printing your own Groot model

Groot’s naughty charm and heart-warming loyalty make him one of the most popular characters in the Marvel Universe. "I’m Groot!" Resonance is far beyond the screen, what better way to celebrate our favorite perceptual tree than to bring him into your physical space? 3D printing provides fans with an incredible way to create their own detailed Groot characters, from cute miniatures to impressive desktop companions. This guide will take you through the entire journey, highlighting the joy and technical considerations that bring Flora Colossus to life step by step.

The charm of the printing guardian:

It is very satisfying to bring the Groot model from your screen and into your hands. It combines creativity, technology and pure fanaticism. Whether you choose cute baby Groot from it Guardians of the Galaxy Vol. 2the fierce warrior Groot (Vol) ended. 3, or the ability of classic potted saplings, custom sizes, postures and even expressions makes every printing unique. This is a personal decoration, a conversation piece or a heartfelt gift that can showcase your craft skills.

3D printing process: from file to image

-

Find the perfect model file:

- Your journey begins with digital 3D models. Many talented artists share their work online. Websites like Thingiverse, Cults3D and Myminifactory are great starting points. Search similar "Big STL," "Large baby model," "Guardian Groot printing," ETC.

- Main things to note: Pay close attention to the model’s:

- Level of details: Complex bark textures, facial expressions, and posture complexity significantly affects the required print quality and the required printer resolution.

- support: Check whether the model is pre-supported or whether it is necessary to manually generate support in the slicing software. Groot’s branched limbs and unique postures usually require careful support planning to prevent print failures.

- scale: The model file size can usually be resized in slicing software. Consider the build volume of the printer and the required final size.

-

Prepare the model: Slicing software:

- Download the STL file of your choice and import it into the slicing software (Cura, Prusaslicer, Simplify3D, etc.). This critical step converts the 3D model into instructions (G code) that your printer understands.

- Basic slicing settings for Groot:

- Layer height: Lower layer heights (e.g., 0.1mm or 0.15mm) are ideal for smooth surfaces (e.g., 0.1mm or 0.15mm) although it increases printing time.

- Fill density: 10-20% is usually enough to save material and time on the decorative model. Higher fills (25%+) are required only if the model bears or requires significant strength (less likely Groot).

- Printing speed: Slower speeds often produce higher quality finishes on complex organic shapes such as Groot.

- support: Critical! Enables overhang support over 45-50 degrees. Tree support or custom support positions in the slicer minimize damage to the delicate bark texture during the removal process. If your printer supports it, consider using soluble support interface materials.

- Raft/Edge: Using edges can help bed adhesion for models with smaller base footprints.

-

Material selection: Bring texture and character:

- PLA: The most popular choice. Easy to print, width range. Looking for a PLA full of wood – sanding and even staining, giving Groot an incredibly realistic wood texture and look. Standard blocks in brown, green or grey also work well.

- PETG: Stronger and more durable than PLA, with good layer adhesion. Perfect for models that may be processed frequently. Available in translucent finishes, it can add interesting effects (e.g., glowing juice!).

- Resin (SLA/MSLA): accomplish Highest Levels of surface details and smoothness, ideal for complex baby pore faces or super detailed bark. Needs post-treatment (washing and curing), but it brings amazing results.

-

Printing itself: Patience is the key:

- Make sure your printer is carefully leveled.

- Apply appropriate adhesion aids (glue sticks, hair spray, PEI paper) for your bed type.

- Carefully monitor the first few layers, as complex organic shapes can sometimes be tricky starters.

- Prepare for potential printing times, especially for larger models or printed at high resolution.

- Post-processing: Expose your guardian:

- Delete support: This is usually the trickiest part of Groot. Be patient and use beautiful tweezers and a flush cutter. Work slowly to avoid breaking twigs or destroying the texture of the bark. Carefully polishing small pieces is essential.

- Grinding: For PLA prints, especially those filled with wood, sanding helps mix layer lines and smooth rough spots. Start with coarse sand and move to finer gravel. Wear a mask with particulate matter.

- Painting and finishing:

- start up: Apply a primer (spray or brush) to create an even base and help paint stick.

- painting: Acrylic paint is perfect. Use a variety of brown, gray, green and even moss tones to highlight the organic nature of Groot. Washing (thin paint) can bring deep texture details. Light dry brushes with highlight colors add depth.

- detail: A tiny brush is the key to the expressions of the eyes and facial. Consider realistic gloss varnish "Wet" Eye.

- Wood finish (optional): For wood-filled PLA, applying wood stains after sanding before painting can significantly enhance the natural cereal effect. Sealed with matte varnish.

Beyond PLA: Possible when your idea needs metal?

While most amateurs print Groot in plastic or resin, their love for the character inspired off-desktop creations. Imagine having intricate Groot themed jewelry, custom bike parts, artistic sculptures or industrial design prototypes in its unique form. This is the need to produce metal manufacturing.

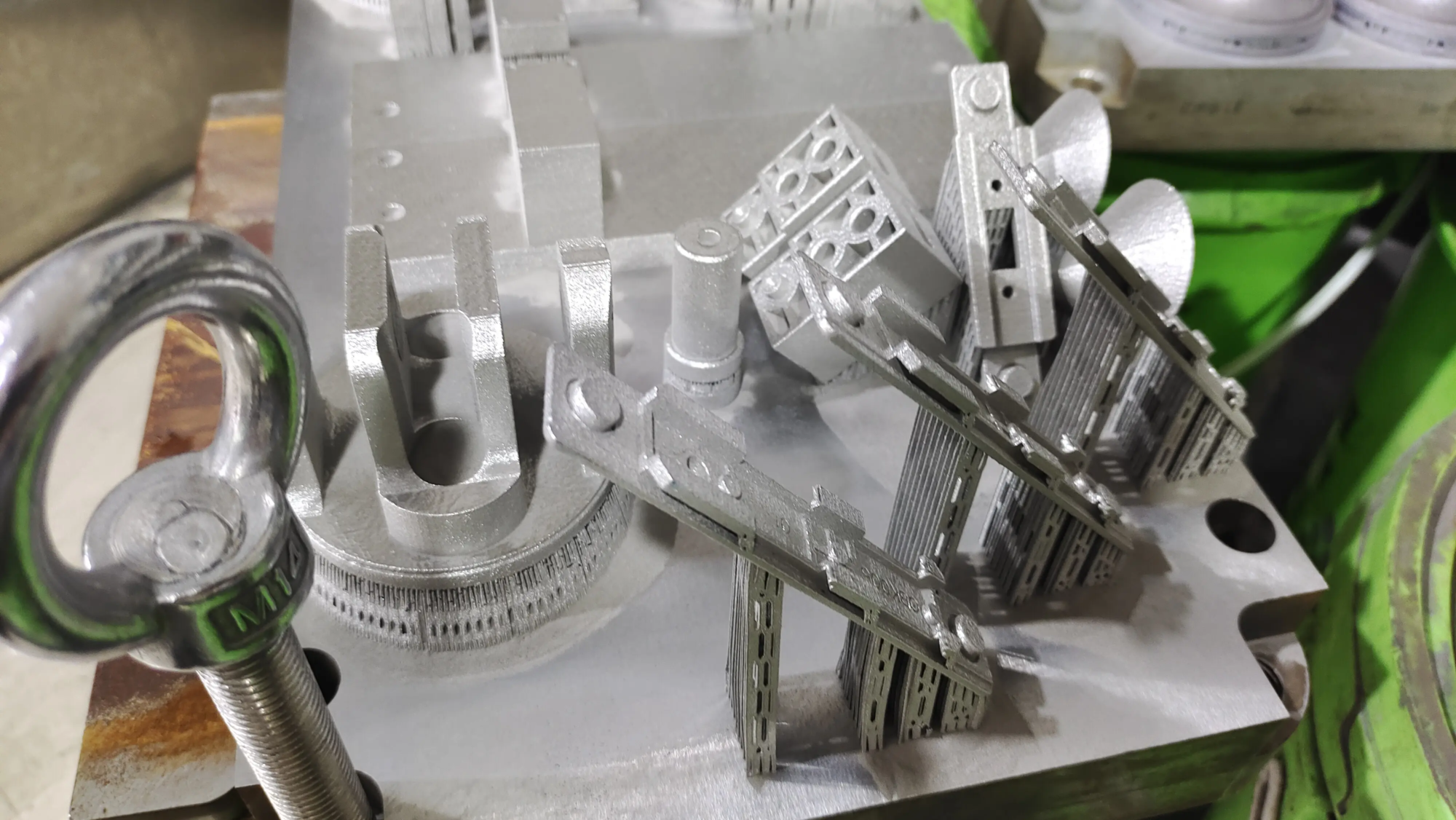

Creating metal objects inspired by Groot involves very different techniques. Selective laser melting (SLM) – High-precision metal additive manufacturing process – is an industrial power behind composite metal parts. SLM uses powerful lasers to fuse fine metal powder layer by layer into fully dense components that traditional machining may encounter. Think of the titanium pendant shaped like a Groot root, or a stainless steel bracket integrated with his signature profile.

Great: Precise location

This is where to work with experts. As a professional rapid prototype manufacturer, Great Advanced leverage SLM 3D printing technology and deep production expertise to solve the toughest metal parts challenges. Understanding the complexity of additive manufacturing (DFAM) design and the behavior of materials during laser melting is critical to success. Especially when targeting details that are often seen in fan-inspired designs such as Groot elements, precision is not negotiable.

Greglime not only stops printing. We provide comprehensive One-stop post-processing and completion service. From critical pressures – utilizing heat treatment and precise removal of support structures to CNC machining for tight tolerance features, surface finishes (polishing, bead blasting, coatings) and meticulous inspections – your metal GROOT-inspired concept can accept complete professional treatments that transform digital brilliance into tangible metal masterpieces. Most materials, such as titanium alloy (TI6AL4V), aluminum alloy (ALSI10MG, ScalMalloy), stainless steel (316L, 17-4PH), nickel alloy (Inconel) and cobalt colloids, can be easily used for reliable customization.

in conclusion

Printing your own 3D Groot model is a meaningful project that combines creative enthusiasm with technical craftsmanship. From finding the perfect digital design to browsing the slicer settings, selecting the right materials and applying a collation touch, the process is a journey in itself. It allows you to create unique superhero fanatics for the shelf.

When home FDM and resin printers make a living from plastic for personal enjoyment, the ambitions of metal interpretation require the ability to manufacture industrial-grade additives. For those joint ventures, choosing a professional partner like Greatlight – equipped with state-of-the-art SLM technology, deep material knowledge and comprehensive post-processing expertise – ensures that your sophisticated complex metal design, whether directly inspired by Groot or requiring similar complexity and strength, can be achieved with the highest quality and reliability. From rapid prototyping to end-use parts, the power created with metal is now easily accessible. We are Groot – we can do anything. Ready to bring your precise metal concept to life? [Explore GreatLight’s Rapid Prototyping & CNC Machining Services] (Consider adding a subtle link placeholder).

FAQ: Print your Groot and metal prototypes

Q1: Where can I find the best Groot 3D model?

A1: Start with famous 3D model repositories such as Thingiverse, Cults3d, myminifactory and Printables. Look for models with good reviews, clear photos of the print result, and check the license (usually a creative sharing for non-commercial use). Searching for the name of a particular artist often produces high-quality results. The paid market also offers incredibly detailed models of professional designers.

Q2: How to prevent the branches and branches of my Groot from breaking after printing or removing?

A2: This is a common challenge!

- support: Use tree support or place the support manually and focus on the most critical overhang. Very slightly (within the recommended limit) in the slicer to increase the support interface Z-distance to make it easy to delete.

- direction: Sometimes, a slightly rotating model can reduce the drooping on the most subtle functions.

- Print settings: Increase the wall/peripheral count of thin sections (3-4 walls). A slightly lower cooling fan speed improves layer bonding. If one copy fails, multiple copies are printed.

- move: Use patience, fine scissors, pinch of the nostrils, and possibly a heat gun (be careful!) to soften the support nearby. If your printer is double-extruded, consider soluble PVA support.

Q3: What are the benefits of using wood-filled PLA for Groot?

A3: Wooden-filled PLA (composite of PLA and fine wood particles) allows you to achieve a very realistic wood texture using standard PLA. It can be almost as smooth as real wood, stained with wood to deepen color changes and mimic grains, and even carved or engraved. It brings tactile authenticity to your Groot model.

Question 4: Is painting necessary, or am I only able to use colored filaments?

A4: Painting significantly improves the final result when printed with brown or grey silk. Painting allows:

- Add depth and dimensions with highlights and shadows.

- Create realistic bark texture with cleaning.

- Accurately define facial features.

- Apply moss green or other accents.

Start and draw unlock the full visual potential of the model.

Q5: Why do I need metal 3D printing to be like Groot-inspired designs?

A5: Love plastic printing is very suitable for decoration. But if you need functional parts – such as custom jewellery (strong buttons, intricate pendants), custom mechanical components (gears with groot aesthetics), durable artwork for outdoor use, industrial prototypes require materials (strength, heat resistance, heat resistance, biocompatibility), or manufacturing industries similar to metal additions (similar to metal). This is about material properties and functional complexity beyond.

Question 6: As mentioned by Greatlight, what material can you actually provide?

A6: GRESTHIMENG usually handles a variety of high-performance alloys suitable for the required application:

- Titanium alloys (such as Ti6al4v): High strength to weight ratio, excellent biocompatibility (excellent for medical equipment/luxury items), corrosion resistance.

- Aluminum (e.g., Alsi10mg, ScalMalloy): Good strength, lightweight, excellent thermal properties.

- Stainless steel (e.g. 316L, 17-4ph): Excellent corrosion resistance, good strength, widely used in functional parts and prototypes.

- Nickel alloys (e.g., Inconel 625/718): Special high temperature strength and corrosion resistance (aerospace, energy).

- Cobalt powder alloy: High wear resistance, biocompatible (dental, medical implant).

Material selection depends entirely on the functional requirements, budget and application of the final section.

Q7: How to ensure accuracy in Greatlight? What post-processing do you do for metal parts?

A7: By:

- Advanced SLM devices: Maintain strict calibration of the laser and reconfiguration system.

- Process expertise: Optimize parameters for each geometry and material.

- DFAM input: Design collaboratively for optimal manufacturing and performance.

Post-processing is essential for SLM parts:- Pressure relief/heat treatment

- Support structure removal (use precise methods such as EDM cutting if needed)

- CNC machining for critical tolerances and mating surfaces

- Surface finish (polishing, bead blasting, vibration finish, paint)

- As needed (X-rays, dye penetrants), non-destructive tests (NDT)

- Comprehensive dimension inspection (CMM, optical scanning)

Question 8: How does Greatlight handle the intellectual property rights of fans creating designs?

A8: Greatlight is designed specifically for rapid prototyping and custom parts production to manufacture physical parts. We strictly respect intellectual property rights. yes Customer Responsibility To ensure they have the right to work based on copyrighted work, any project (such as Groot elements) can be produced. We discuss designs only in the context of quality requirements for manufacturing feasibility, material selection and physical geometric shapes. We recommend that customers obtain the original design or obtain a license before commercially reproducing copyrighted characters.