Entering Bounty Hunter’s Boots: The Ultimate Guide to Printing Your Own Boba Fett Helmet

The iconic T-Visor. Unique Mandalorian armored line. Fighting green and red. Boba Fett’s helmet is more than just a headdress. It’s a symbol that instantly recognizes generations of Star Wars fans. While the screen-accurate replicas may cost money, the rise of accessible 3D printing has opened up the galaxy for enthusiastic amateurs: you can now print out this legendary work yourself. But it’s a journey, not just a print button. This guide will provide you with the process from digital files to Mandalorian Masterpiece, while highlighting how manufacturing expertise can enhance your project.

Why 3D Print Your Boba Fett? It’s about Beskar Pride

Purchasing a prefabricated helmet can instantly satisfy your desire, but the desire to make it yourself is deeper:

- Final Customization: Want to wear ESB gray cheeks? Dent configuration before painting? Or the original Jango-inspired blue? Printing allows you to choose Exactly Which version or create your own unique variant.

- A sense of accomplishment: Building something like this complex can bring great satisfaction, i.e. buying mismatch. The process itself becomes part of the story.

- Cost-effective (long-term): While it requires upfront effort and material, printing may be much cheaper than high-end licensed replicas, especially for common actors or prop makers.

- Perfect for: Scalability during slices means you can make sure your helmet is right your Comfortable place.

Print Pilgrimage: Print from file to finished

1. Finding sacred text (STLS):

The journey begins with getting the digital blueprint – STL file. Many talented designers share their explanations online (usually on platforms like Thingiverse, Prinbables, Cults3d, or Myminifactory). Popular files include The Empire Counterattack,,,,, Mandalorianeven stylized. Crucial: Always respect intellectual property rights. Pay the documents if required, never distribute paid documents and avoid direct copies of the official licensed merchandise model unless explicitly released to print.

2. Number forgery (slicing):

Using software like Prusaslicer, Cura, or Bambu Studio, your 3D model cuts it into thin printable layers. Main things to note:

- Zoom: Measure your head! The model is expanded accordingly to ensure that sufficient filling and space for electronic devices can be ensured if needed. It is usually necessary to increase the head circumference size of 10-15%.

- Print settings:

- Material selection: PLA is common and easy, but can twist and soften in heat. PETG has better temperature resistance and durability, making it perfect for role-playing. ABS requires fences and good ventilation, but can smooth the acetone (although ABS’Fumes require caution). For internal structure and Critical high pressure external components (such as rangefinder stems), professional Metal solutions become striking.

- Layer height: Lower layer heights (0.1-0.2mm) produce smoother surfaces, but greatly increases printing time. Need to balance. It is desirable to be 0.15-0.3mm as a typical range.

- filling: Don’t waste materials to make it strong! 15-30% of the filler (usually recommended to use energy or grid patterns) provides sufficient strength without inappropriate quality or printing time.

- support: Ears, keyholes and domes often require complex support. Dialing in support settings (interface density/Z-distance) is critical for later smoother surfaces and is easier to remove.

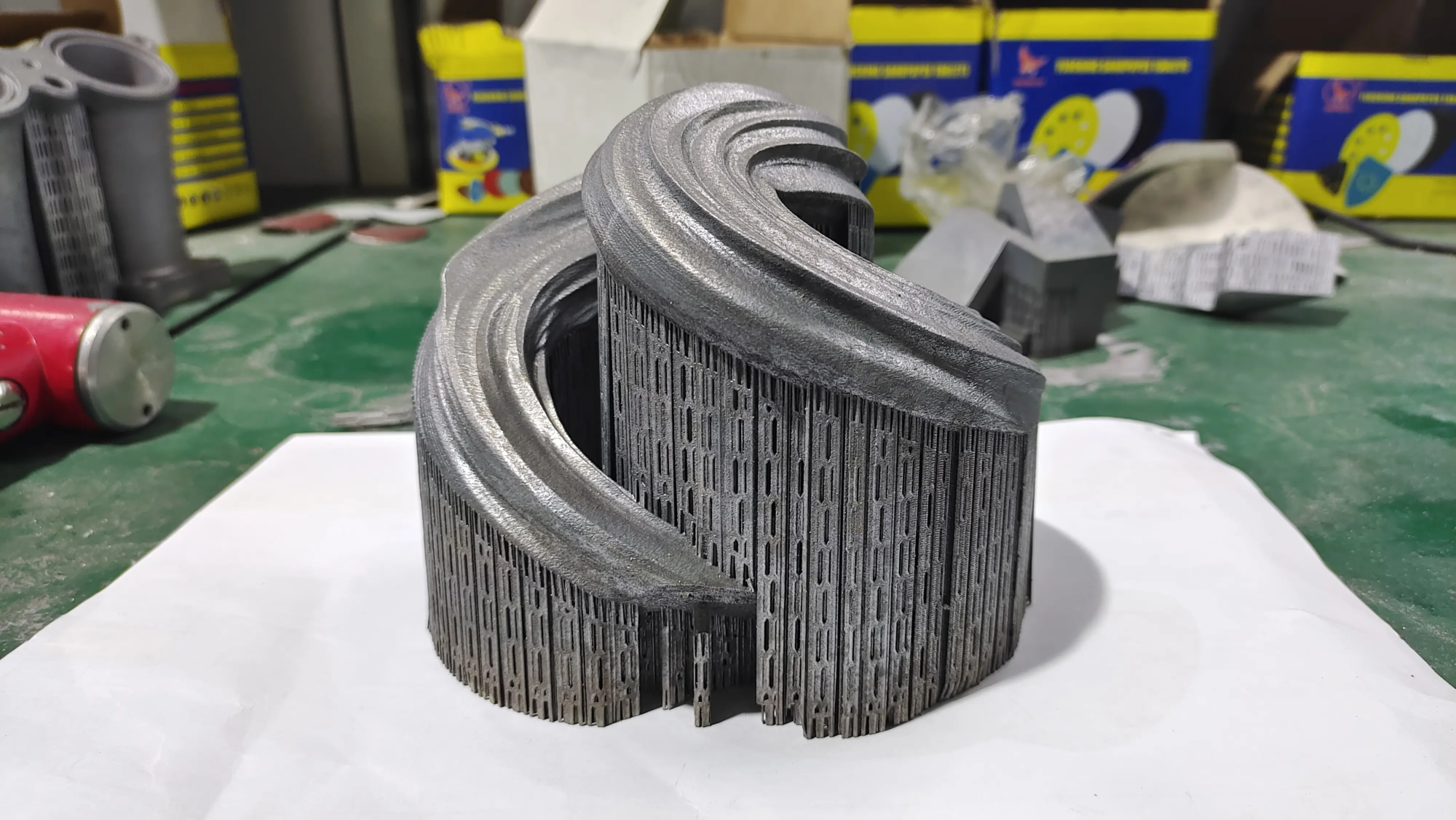

3. Install campaigns (conference):

Large helmets rarely print on consumer printers. Multiple parts are desirable (dome half, ears, keyholes, vent ports, rangefinder assembly). The conference involves:

- Dry accessories: Test assembly forward Glue to ensure perfect alignment. Tape is your friend.

- join in: High-strength epoxy resins (such as JB welding plastic bolts) or specialized plastic welding glue are the best. ca glue ("Super lue") may be fragile and prone to pressure cracks. Drying time must be respected.

- seam: This is a critical step. The sand-printed seams are carefully printed. Fill gaps or small amounts of defects with high-quality bond/auto glass putty, wood filler or dedicated 3D printed filler such as XTC-3D. Multiple thin layers are gradually polished through sand particles (from heavy duty work of about 80 particles to more than 400 final smooth) are key.

4. Perfect path (sand, primer, polish, primer…):

This stage separates the toy from the replica. It is repetitive, but essential.

- Eliminate layer lines: Grind the entire surface, through the sand grains (usually starting from ~120/180 and initially through 400/600 grit). Round motion and sanding blocks help avoid capsules.

- Seams disappear: Focus your intense efforts on the seams you fill. They should become invisible before moving forward.

- start up: Spray with high-build car fill primer. This acts as a surface, revealing any remaining layer lines, printing artifacts or defects. Let it heal completely.

- Grind again: The wet sand starts with 400 sand noodles from the surface of the primer and then moves to 600, 800, or even 1000 grain sizes for glass smooth finish. Repeat the original/sand cycle (even 3-4 times) until the surface is flawless. Yes, this is labor-intensive!

5. Lay basteel (painting and weathering):

Now for art. Boba Fett is definition Work through his combat damage and unique paint.

- Basic jacket: Use a spray paint or spray gun to carefully apply the core color. Tape is essential. Key colors: Hunter green, charcoal grey, crimson red, olive monotony, silver. Smooth, even coats are crucial.

- detail: Hand-painted details such as ear symbols, kill stripes or sun-visual decorations. Use a fine brush and patience.

- Sealed and weathered: Apply a transparent coat. Then, the fun begins! Clean with acrylic (dark brown, black), dry brush (with silver or lighter base color), sponge crumbs (dab silver/grey clever), and even direction sprays for scratching and blasting marks. Less more! Once satisfied, seal again.

6. Final touch (electronics and accessories):

Lift the helmet:

- Sun visor: It is crucial for wearability and authenticity. It is common to have dark green motorcycle visor material or replace welded masks (carefully cut and shape). Fix it inside.

- filling: Comfortable helmet filler or foam ensures fit, safety and sweat during wear.

- electronic: The LEDs of the status indicator can be installed, the servers for the stalk of the rangefinder, and even the fan system for airflow can be installed. Cabling requires clean routing and power solutions (batteries).

- Rangefinder stem: This thin protruding element can easily break, especially when printed in plastic. Its mechanism (if electric) requires strong tolerance management. This is a primary candidate for considering professional services.

Beyond PLA and PETG: When your helmet needs Mandalorian grade material

Although consumer FDM printers excel in plastic, Boba Fett’s armor evokes durability. Components that withstand pressure – especially Range finder stem Or potential attachment clips and hinges – can benefit greatly from metal. Here, professional manufacturing expertise becomes your place.

Creating complex, sturdy, lightweight metal parts for a helmet requires:

- Material expertise: Choose the right alloy (aluminum, titanium, stainless steel) for strength to weight ratio and compatibility with other materials.

- Precision technology: High-end SLM (Selective Laser Melting) 3D printing creates complex, durable metal parts directly from digital designs, ideal for complex geometric shapes such as stem mechanisms. CNC machining provides tight tolerances for functional components.

- Post-processing: Metal finishes (smooth, polished) ensure seamless integration of parts.

- Robustness and durability: Metal components are much less likely to be captured during treatment, transportation or routine wear – critical for delicate exposed parts.

Why consider supporting your Beskar ambitions?

While DIY printing achieves a core vision, achieving true professional-grade robustness or integrating custom metal elements often requires advanced features. As a leader in rapid prototyping and custom manufacturing, Great Have the expertise and technology to enhance your project:

- Advanced SLM Metal 3D Printing: Specializes in the manufacture of composite, durable metal components directly from digital files. Need a stronger rangefinder stem hinge or a custom mounting bracket? SLM provides a solid solution in metals such as aluminum alloys (ALSI10MG), stainless steel (316L), or titanium.

- Precision machining: In addition to RP, we also offer high-precision CNC machining for parts that require ultra-tight tolerances and superior surface finishes – essential for functional mechanical elements such as servo frames.

- One-stop post-processing: From polishing and smoothing (including complex interior geometry difficult by hand tools) to shooting, polishing, plating, powder coating and custom painting – we deal with labor-intensive finishes that define quality parts.

- Material versatility: A wide range of material options outside of plastics for consumers.

- Speed and scalability: Do critical components require multiple replicas or quick turnaround? Automated industrial workflows have a significant speed advantage over home printing and are used for complex or orderly batch processing.

Printing your Boba Fett helmet is an incredible adventure in creation. And while the DIY printing journey makes a lot of sense, please understand when and how Professional manufacturing expertise As Greatlight offers, specific challenges can be solved, especially in terms of durability, precision metal parts and high-end finishes – giving you the ability to build a helmet worthy of Mos Eisley’s most terrifying bounty hunter.

in conclusion

3D printing your own Boba Fett helmet is a very meaningful project that blends model building, art and deep connections to the Star Wars universe. It requires patience, attention to detail and the willingness to learn as you browse through various stages – procurement, printing, assembly, finishing and painting. However, the result is truly unique personal craft: functional wearable art, full of satisfaction that makes this iconic symbol come to life with your own hands.

While consumer-grade printers and filaments offer great accessibility, achieving durability and crispness involves consistent efforts, just like advanced replicas. Recognizing the unique advantages of professional manufacturing, especially SLM metal printing and professional finishes, with demanding components or high-quality results – provides additional possibilities. Whether you solve every step yourself or leverage expert services to make these critical enhancements, this journey will open the way to the door to own Beskar Steel Legend. So start those printers, get sandpaper ready, and probably work with your filament!

FAQ: Print and build your Boba Fett helmet

Q: Where can I find free Boba Fett helmet STL files?

A: Well-known platforms like Thingiverse and Printables have numerous free designs created by talented members of the 3D printing community. Popular files include "Boba Fett Helmet – Mix" or various versions such as designers (usually required for name credit). remember: Always check the license terms! Do not distribute paid documents without permission.

Q: How long does it take to print the entire helmet?

Answer: Height is variable! Factors include: printer speed, layer height (quality setting), fill percentage, support requirements and part quantity. Expected Total printing time Over a time range of 60 to 150 hours, multiple parts are usually printed simultaneously or continuously over a few days or weeks. Components, polishing and painting phases add more time.

Q: Which 3D printer is best for helmets?

A: A large build volume printer (usually >== 280x280x300mm) is required to print out huge parts (such as the dome half). Reliability is the key to long-term printing. Popular options include Creality (CR-10 series, Ender 5 Plus), AnyCubic (Kobra Max), Elegoo (Neptune 4 Max), Prusa (I3 MK3S+, XL) or Bambu Labs (P1S, X1C). Corexy printers usually offer speed advantages. Buy the largest reliable printer you can afford.

Q: PLA or PETG? What material is the best?

A: Both work, but it is generally recommended to use PETG as a better all-round option for character helmets:

- PETG: More powerful and influential than PLA. Higher temperature resistance (not soft or warp in hot car or under conference lights). Good layer adhesion. Printing is a little tricky compared to PLA (stringed).

- PLA: Easier to print and provide good surface details. Softer and easier to catch under impact. Can be significantly distorted in a thermal environment.

- ABS: Hard and acetone smooth, but easily twisted, smells during printing and requires ventilation/enclosure.

- Asa: UV and weather resistance, such as ABS, but with less warping, still require closure/ventilation.

Q: The polishing/priming phase is disappearing forever! Are there any skills?

A: Unfortunately yes time consuming. Tip:

- Start with coarse sand (80-120) only in places with large slits or spots. Don’t use them to attack the entire surface first.

- Use sand blocks on flat areas, not just fingers.

- Tall building primer is your best friend. It is full of micro-drawing and reveals lows/highs. Spray in a thin coat.

- Wet lines (especially used from above 400 grits) are smoother and reduces clogging.

- be patient. Stop when you don’t see the /payment layer line or the blemish under the primer. The rush show in the final paint.

Q: Do I really need metal parts? The PLA seems to be strong enough.

A: It depends. For a carefully worn main helmet shell, a PLA or PETG is usually sufficient. Howeverfor criticism Thin,,,,, High pressureoften Repositioning components like Range finder stemplastic may be easily captured over time, especially when dealing with or using servo motor accessories. Metal components printed by SLM or CNC machined provide great strength, stiffness and life for these fragile parts.

Q: Can services like Greatlight help build the entire helmet?

A: Rapid prototype service, etc. Great Best performing in specific areas of support:

- Complex metal parts: Made a durable rangefinder stem, sensor knob, hinge or mounting bracket with SLM Metal 3D printing or CNC.

- Precision machining: Ensure that critical functional sizes (such as servo brackets) are perfect.

- High-end post-processing: Provides smooth solutions (such as steam polishing of resin parts or advanced processing of printed metals), complex grinding/surface preparation, and professional painting/fitting that can be difficult to obtain complex geometric shapes at home.

- Large capacity: Efficiently manufacture multiple identical components. for All Helmet components are printed in plastic, and for enthusiasts, unless they seek super-optimized production methods, they are usually more cost-effective and beneficial.

Q: Where can I find templates for weathering and painting?

A: There are many resources online! Looking for Boba Fett Studio Scale Models, Prop Replica Drawing Tutorials, dedicated Mandalorian Mercs Forum/Clothing Club and Video Tutorials (YouTube: Punished Props, Galaxy Armory, Built Candidly, SKS Props, etc.). It is crucial to refer to high-quality photos from official sources or museum exhibitions. Creating your own map from reference lenses is part of the challenge and fun! Primer Guide: Dark Silver Primer, Dark Green (Hunter Green), Olive Monochrome, Dark Red, Charcoal Gray, Rusty Red, Light Gray for Crush.